Environmental-friendly composite dispersing yellow dye composition and dye

A technology for compound disperse and yellow dyes, applied in the field of environment-friendly compound disperse yellow dye compositions, can solve the problems of limited alkali resistance, poor golden sublimation fastness, unsatisfactory light fastness, etc. The effect of improved fastness, good market prospects, high light fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~20

[0036] According to the data shown in Table 1, dye component A, dye component B, dye component C and auxiliary agents (dispersant MF, diffusing agent CNF, sodium lignosulfonate), after adding water and blending, use a sand mill Grind and disperse, followed by spray drying.

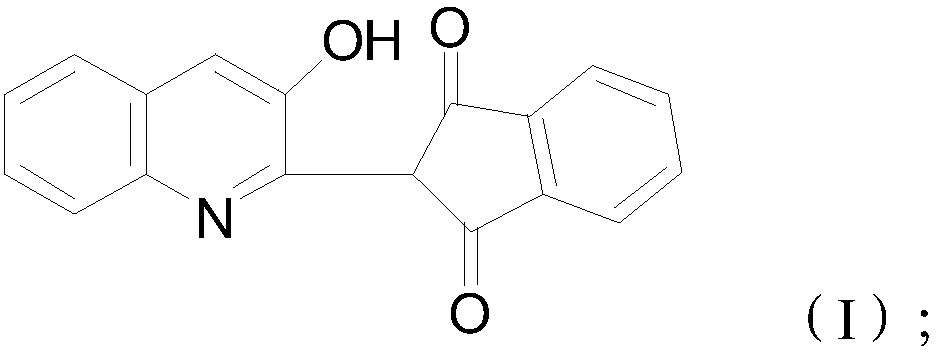

[0037] Wherein, component A can adopt commercially available product, the dispersion yellow 54# that Zhejiang Shanyu Technology Co., Ltd. produces;

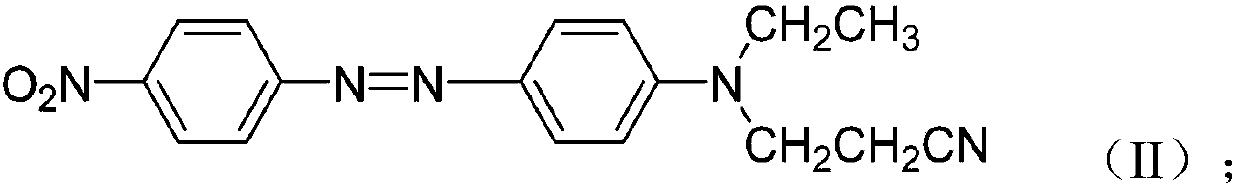

[0038] Component B can use Disperse Orange 25# produced by Zhejiang Shanyu Science and Technology Co., Ltd.;

[0039] Component C can use Disperse Orange 29# produced by Zhejiang Shuangguan Dye Co., Ltd.;

[0040] Table 1 (weight unit: g)

[0041]

[0042]

Embodiment 19

[0048] The yellow disperse dye composition that above-mentioned embodiment is made carries out performance test, and test method is as follows:

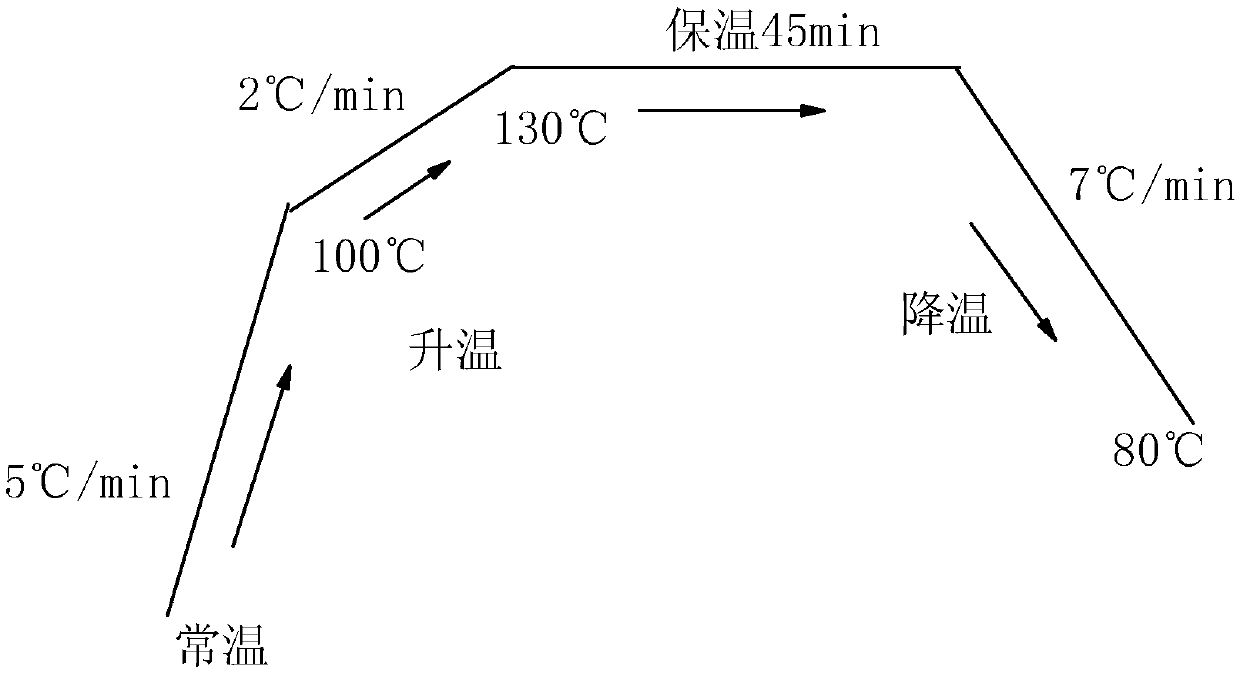

[0049] According to the method similar to GB / T2394-2003, each take 0.5 grams of the disperse dyes prepared in Examples 1 to 18, Comparative Examples 1 to 3, and the comparative samples prepared in Comparative Examples 1 to 3, and prepare them with water so that the concentration is 0.5g / 500ml of disperse dye suspension, mix 20ml with 80ml of water, adjust the pH value of the dyeing bath to 5 with acetic acid / sodium acetate, then raise the temperature to 60°C, and put 2g of polyester fiber fabric respectively, press figure 1 Carry out high temperature and high pressure dyeing, cool to 80 ℃ and sample.

[0050] Observe the shade of the cloth sample and adopt GB / T2397-2012 (lifting force), GB / T8427-2008 (light fastness), GB / T3921-2008 (washing fastness), GB / T3920-2008 (rubbing fastness), GB / T5718-1997 (sublimation fastness) measures i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap