Automatic temperature-regulating bio-engineering reaction kettle

A bioengineering and reactor technology, which is applied in the field of automatic temperature-regulating bioengineering reactors, can solve problems such as inconvenient temperature control, and achieve the effects of prolonging service life, ensuring consistency, and uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

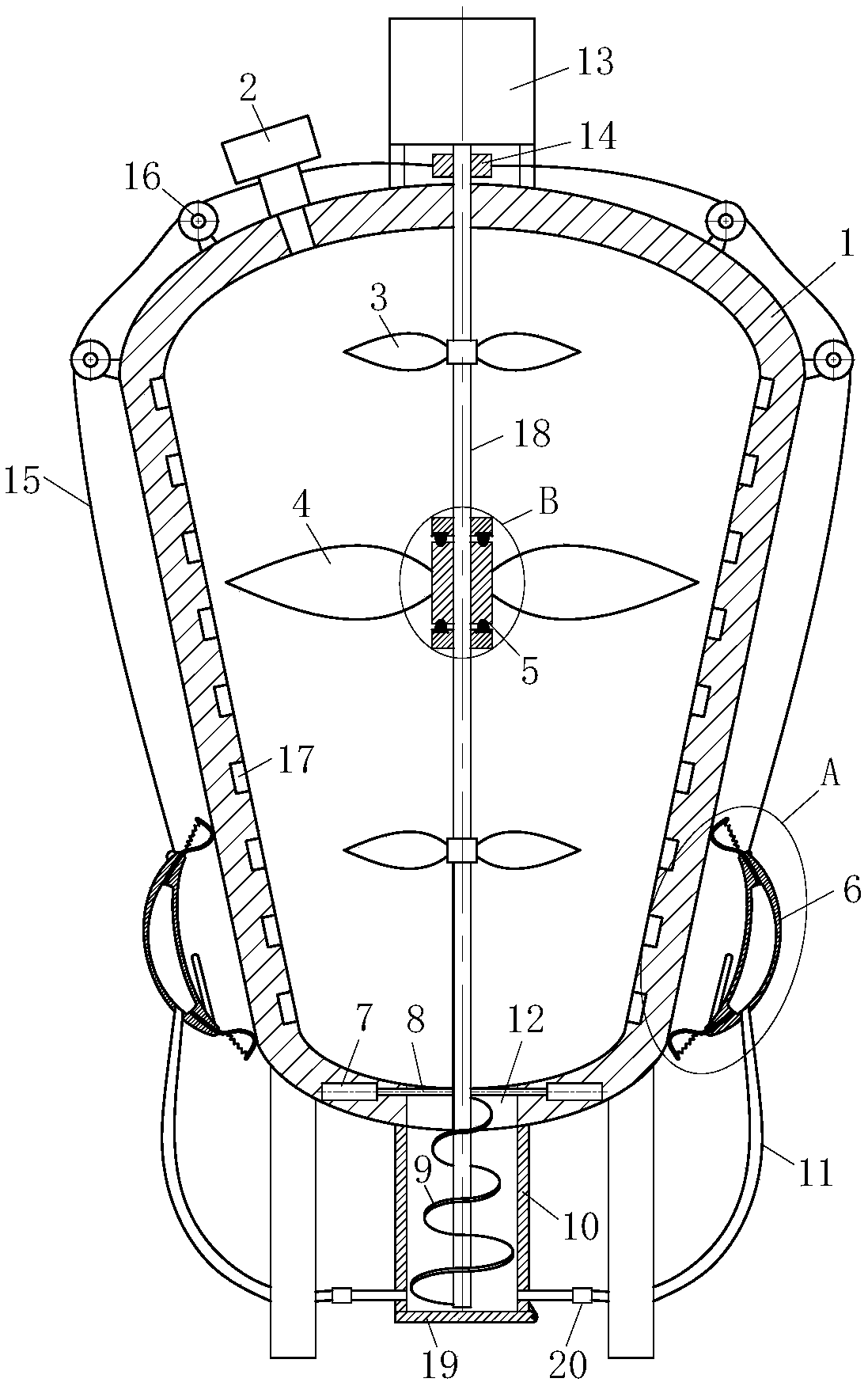

[0019] use Figure 1-Figure 4 An automatic temperature-regulating bioengineering reactor according to an embodiment of the present invention is described as follows.

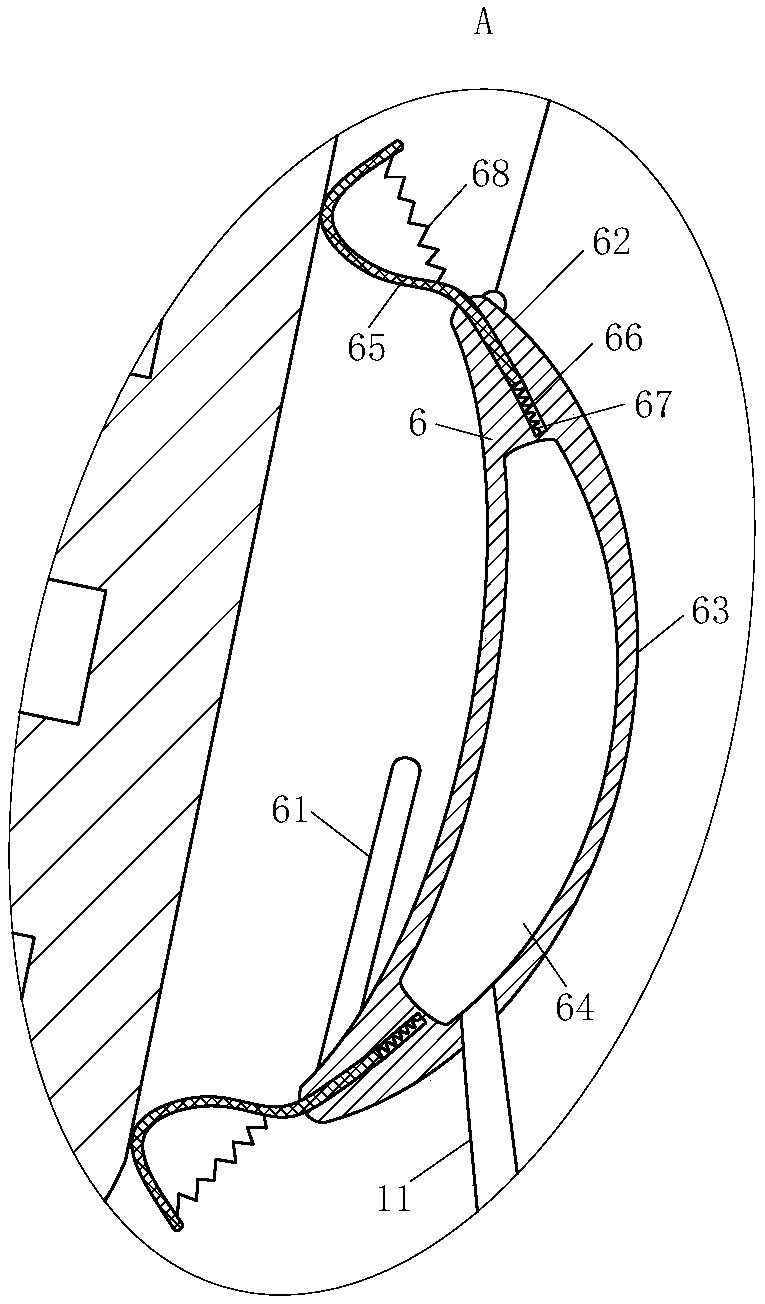

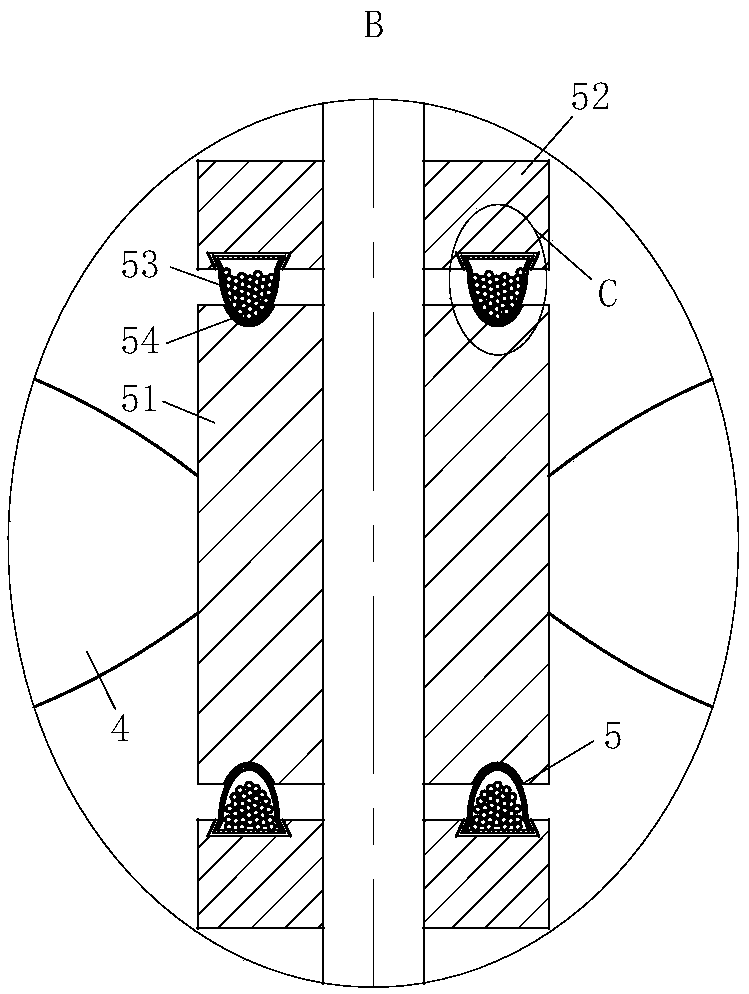

[0020] Such as figure 1 As shown, an automatic temperature-regulating bioengineering reactor according to the present invention includes a reactor 1, a feed port 2, a heat conduction module 6 and a discharge port 12, and the top of the reactor 1 is provided with a feed Port 2, the top of the reaction kettle 1 is connected to the motor 13 through the support frame, the output shaft of the motor 13 is connected to the rotating rod 18, and one end of the rotating rod 18 extends to the inside of the reaction kettle 1, and the external top and bottom ends of the rotating rod 18 are located The first paddles 3 are arranged at each place, and the outer part of the rotating rod 18 is located at the middle position of the two first paddles 3 to be provided with a second paddle 4, and the diameter of the second paddle 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com