Bottom Blowing Argon Method with Four Hole Circulation for Rapid Mixing of Molten Steel

A bottom blowing argon and mixing technology, applied in the field of metallurgical refining outside the furnace, can solve the problems of high efficiency and high quality steel production constraints, whether argon gas can be fully used to stir molten steel, and the cleanliness of molten steel needs to be improved. The effect of shortening the mixing time of molten steel, improving the cleanliness of molten steel and smelting efficiency, and reducing the dead volume in the ladle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

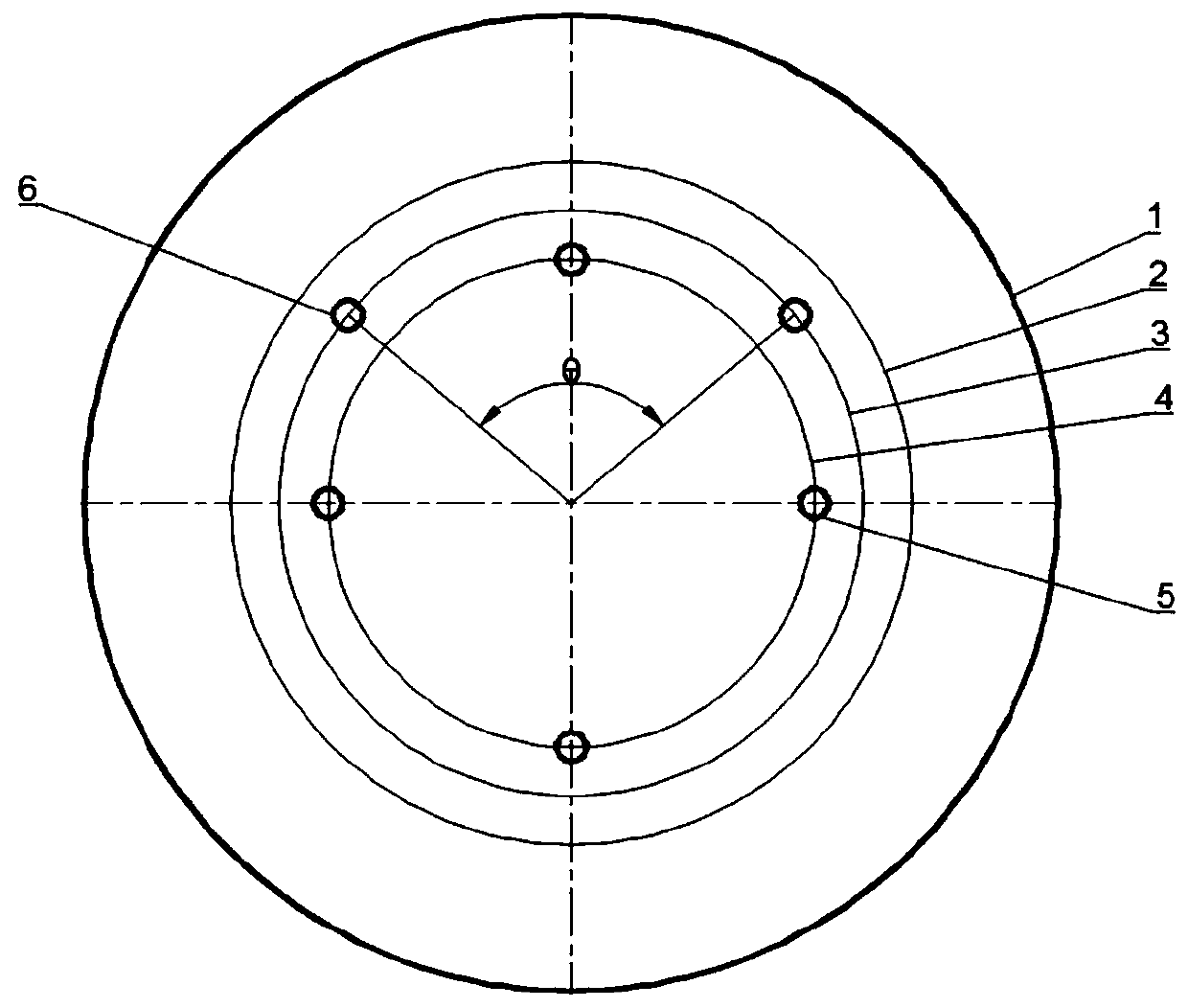

[0023] The bottom of the 110t ladle is located at a distance of 0.5R from the center of the bottom. 4 There are four argon blowing holes 5 evenly distributed, located at a distance of 0.6R from the center of the bottom. figure 1 ). The four argon blowing holes are blown in sequence sequentially, and the blowing flow rate of the sine wave peak is 8π~20πm 3 / h, the total blowing flow rate of the four argon blowing holes is 16~40m 3 / h, the cycle time is 2t. See Figure 4 . In the case of the same total flow rate of bottom blowing argon, the shortest mixing time of double-hole uniform rate bottom blowing is 69s, while the shortest mixing time of the four-hole circulating bottom blowing argon method of the present invention is 62s, and the mixing time is shortened by 10 %.

Embodiment 2

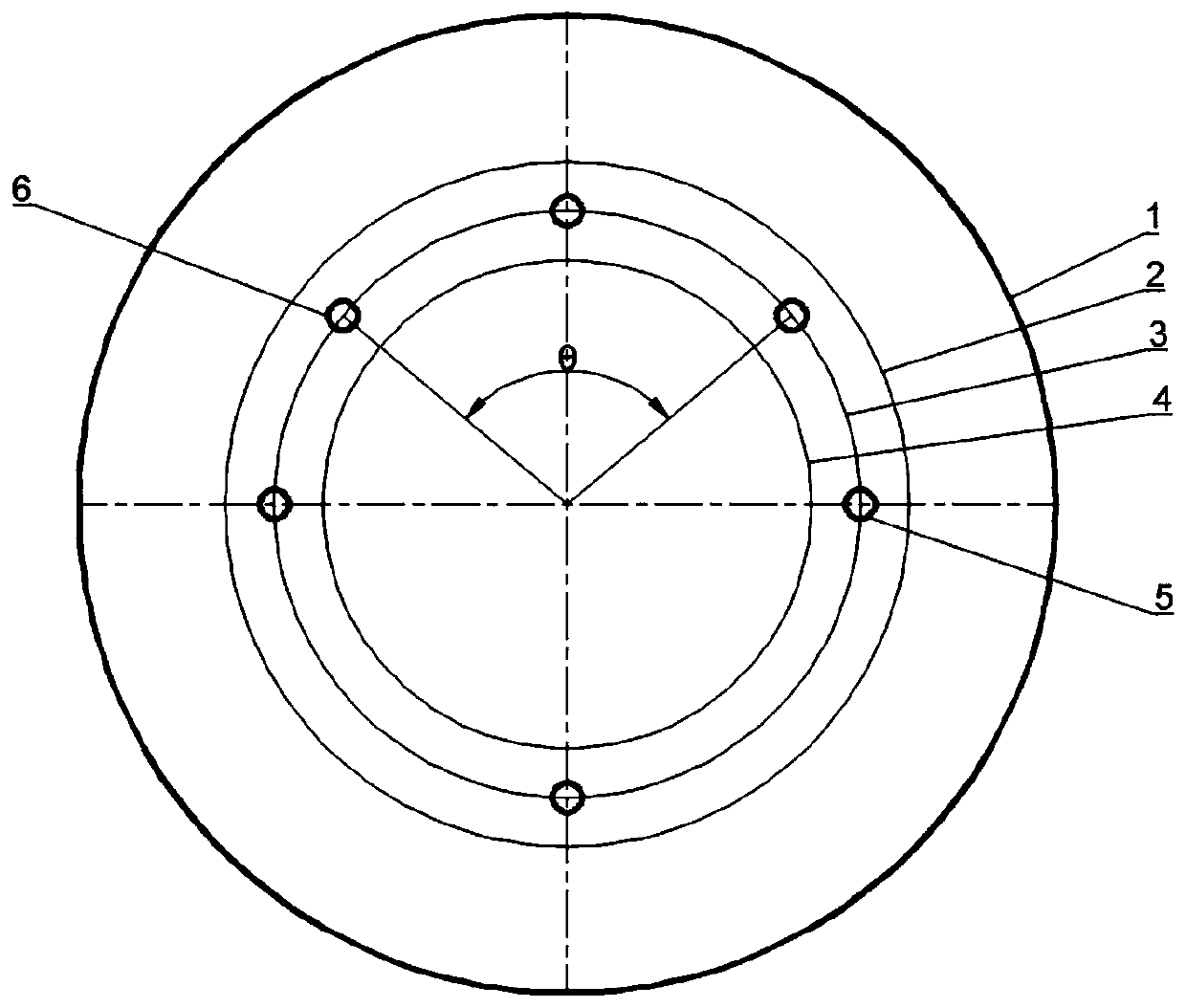

[0025] The bottom of the 110t ladle is located at a distance of 0.6R from the center of the bottom, 3 and four argon blowing holes 5 are evenly distributed, and are located at a distance of 0.6R from the center of the bottom. figure 2 ). The four argon blowing holes are blown in sequence sequentially, and the blowing flow rate of the sine wave peak is 8π~20πm 3 / h, the total blowing flow rate of the four argon blowing holes is 16~40m 3 / h, the cycle time is 4t. In a cycle period, the blowing flow changes of the four air holes are shown in Figure 4 . Under the condition that the total flow rate of bottom blowing argon is the same, the shortest mixing time of double-hole uniform rate bottom blowing is 69s, while the shortest mixing time of the four-hole circulation bottom blowing argon method of the present invention is 60s, and the mixing time is shortened by 13 %.

Embodiment 3

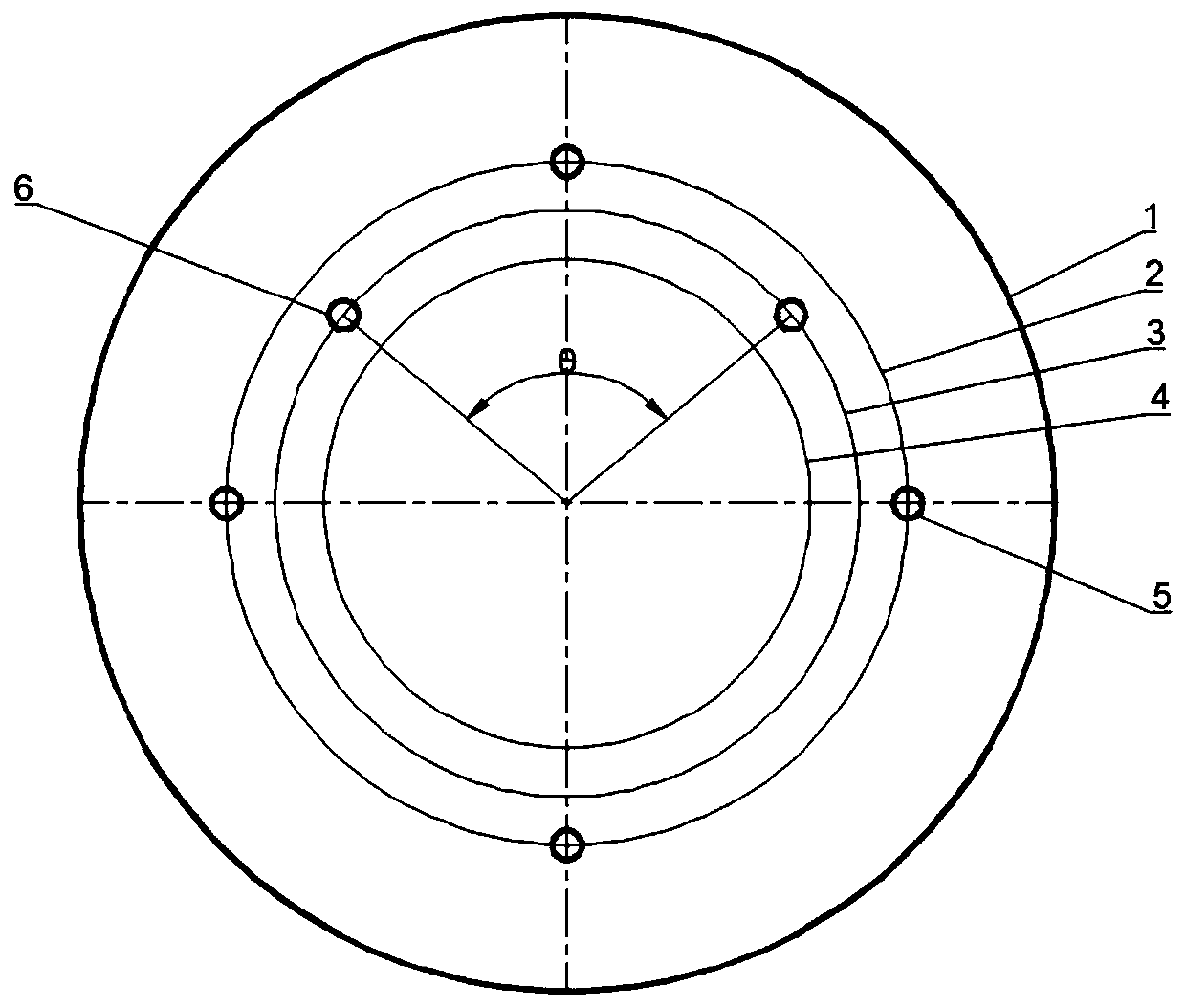

[0027] The bottom of the 110t ladle is located at 0.7R from the center of the bottom 2 There are four argon blowing holes 5 evenly distributed at 0.6R from the center of the bottom 3 Double holes 6 are arranged, and the angle θ between the double holes is 100° (see image 3 ). The four argon blowing holes are blown in sequence sequentially, and the blowing flow rate of the sine wave peak is 8π~20πm 3 / h, the total blowing flow rate of the four argon blowing holes is 16~40m 3 / h, the cycle time is t. In one cycle, the blowing rate of the four air holes changes as shown in Figure 4 . Under the condition that the total flow rate of bottom blowing argon is the same, the shortest mixing time of double-hole uniform rate bottom blowing is 69s, while the shortest mixing time of the four-hole circulation bottom blowing argon method of the present invention is 59s, and the mixing time is shortened by 14.5 %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com