Sley system for high-speed rapier loom

A rapier loom and reed technology, applied in looms, textiles, textiles and papermaking, etc., can solve the problems of restricting the weaving quality and weaving efficiency of fabrics, cumbersome installation, arousing strong vibration and noise, etc., so as to improve the fabric quality. Weaving quality and weaving efficiency, meeting compression requirements, the effect of reducing the deformation of the sled

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

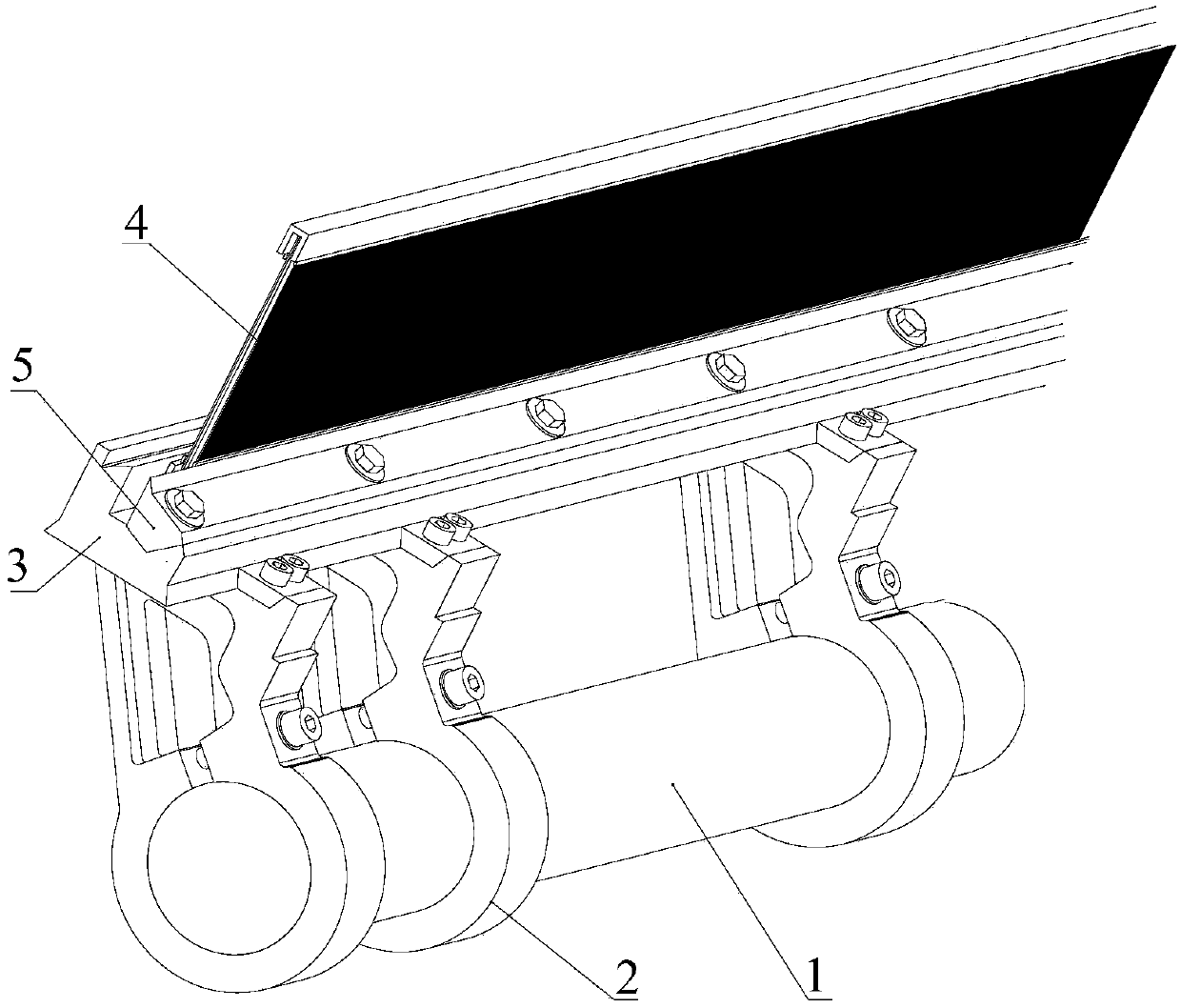

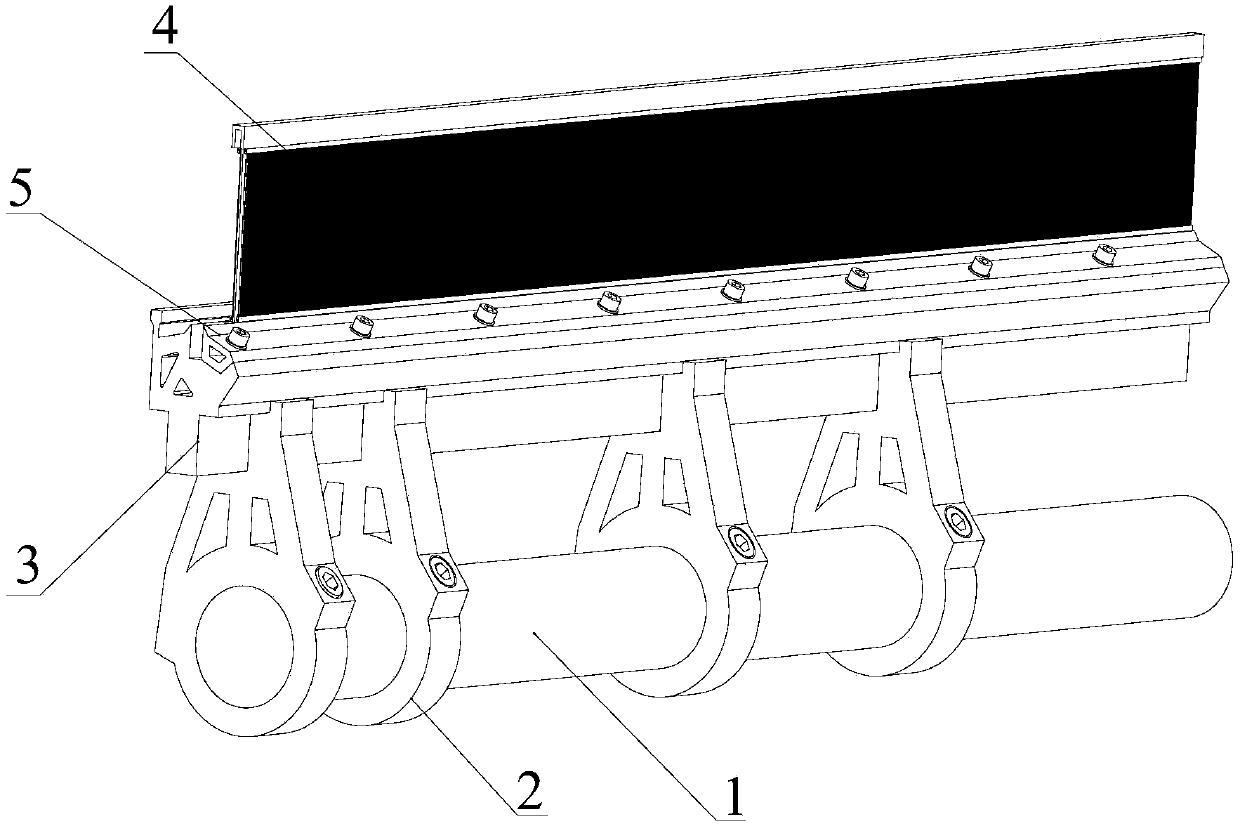

[0023] A sley system applied to a high-speed rapier loom, used for connecting a swing shaft 1 and a steel buckle 4, including a sley 3 and a plurality of sley feet 2;

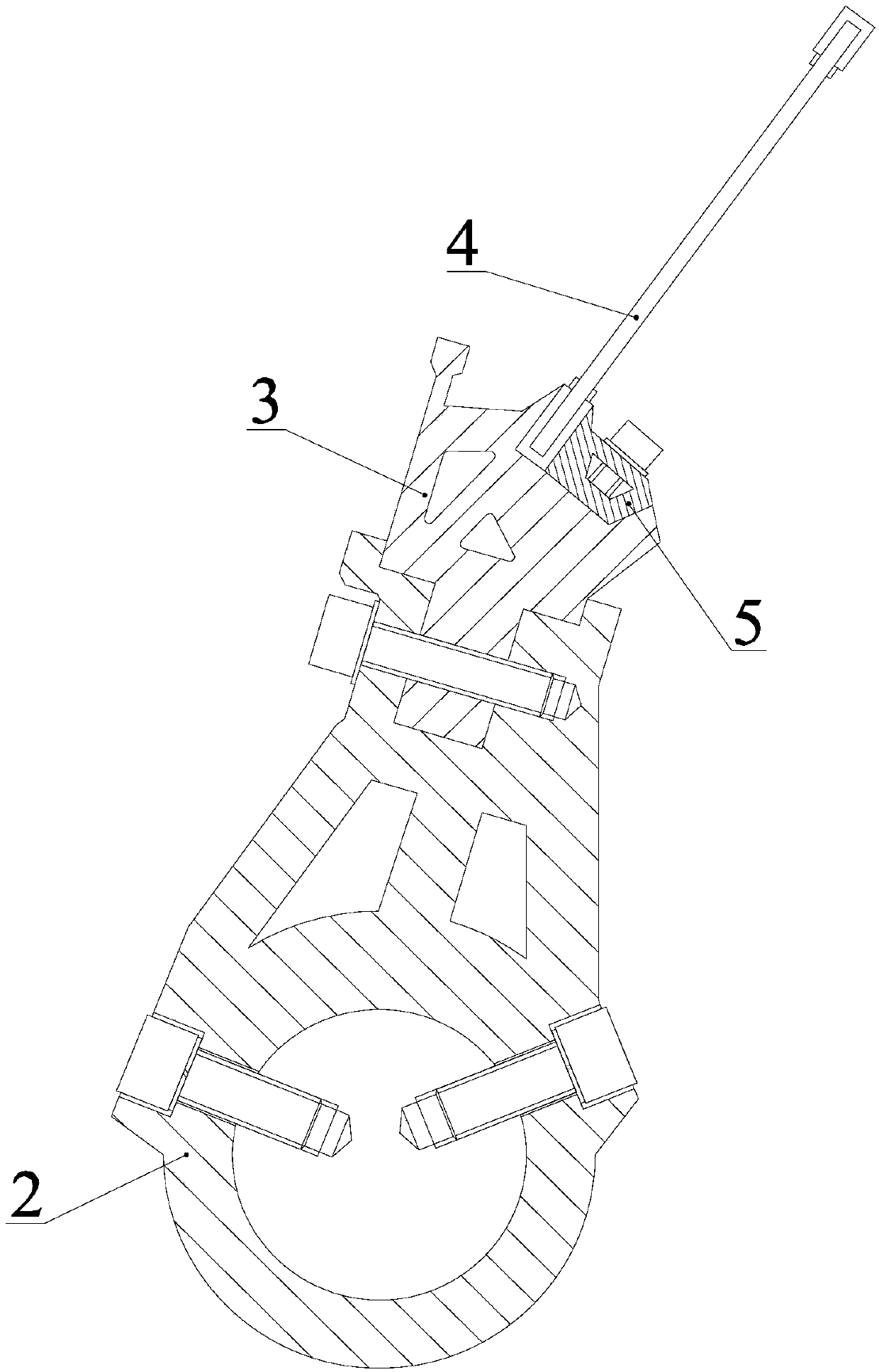

[0024] The outer contour of the longitudinal section of the sley foot 2 is in the shape of a drop or a drop-like shape as a whole, with a through hole on the lower side and a support frame on the upper side; at least two screw holes are provided on the side of the through hole position; preferably, The positions of the screw holes provided on the side walls of the through hole positions of a plurality of sley feet are all the same; as a specific embodiment of the present invention, as Figure 2-4 As shown, two screw holes are provided on the side walls of the through holes of the plurality of sley feet 2, which are respectively symmetrically arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com