3D (three-dimensional) effect PVC (polyvinyl chloride) decoration plate and 3D printing production method thereof

A PVC board and production method technology, applied in the post-processing of printing, copying/marking method, printing and other directions, can solve the mechanical property testing of decorative boards, can not become a qualified decorative board product, and the ink firmness cannot reach the wear resistance of decorative boards. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following is further described with regard to specific embodiments:

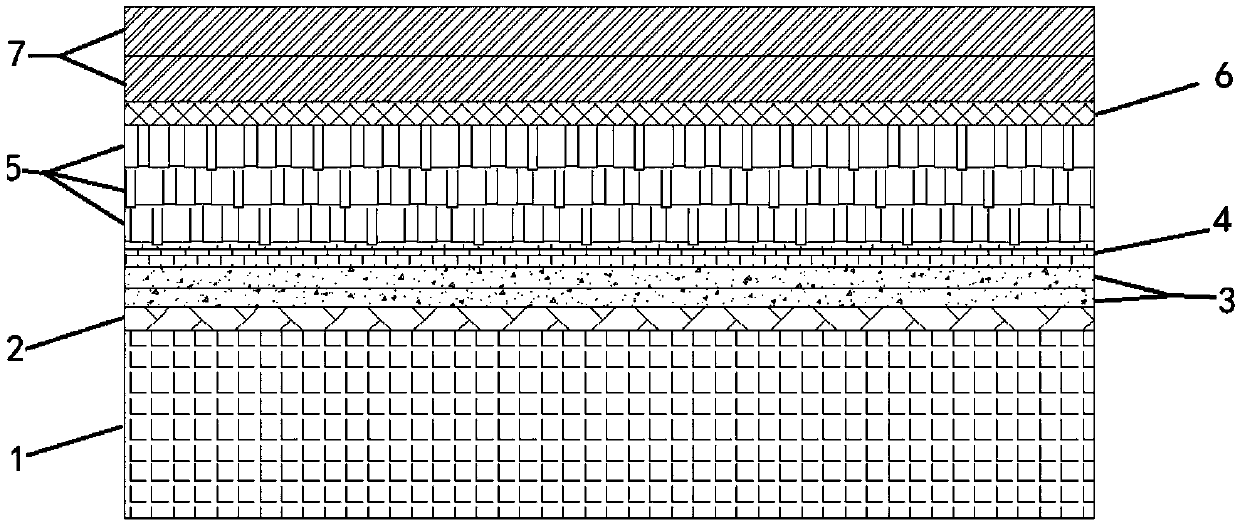

[0028] The decorative panels that need to be made in this example are as follows figure 1 , including the PVC board base material, there are UV primer layer, UV white paint layer, pattern layer, UV wear-resistant paint layer, concave-convex effect layer, UV topcoat layer on the PVC board base material in sequence from bottom to top. The UV white paint layer has 2 layers, the UV wear-resistant paint layer has 3 layers, and the UV topcoat layer has 2 layers.

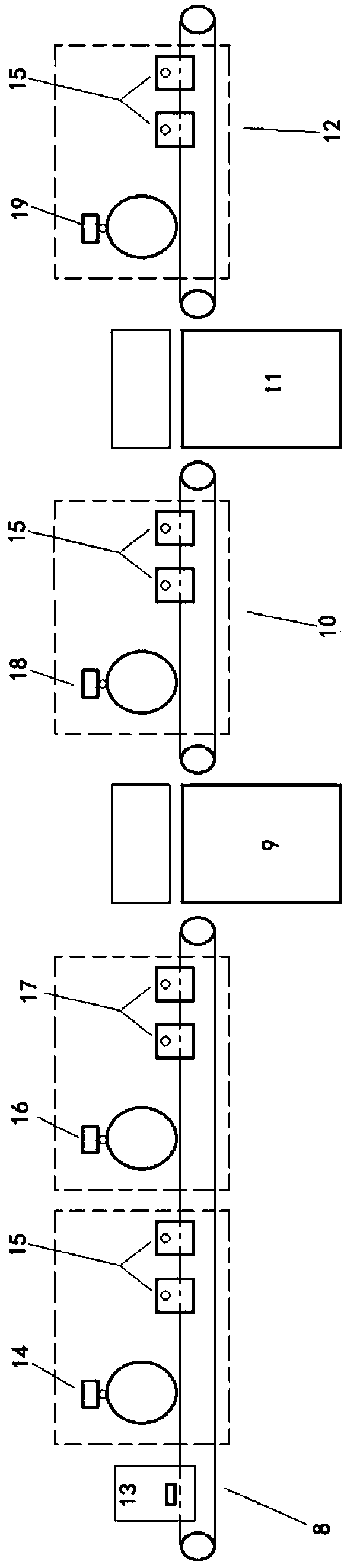

[0029] Such as figure 2 The dedicated assembly line includes at least three conveyor belts; the first flat inkjet printer for printing patterns is placed between the first and second conveyor belts; the second flat inkjet printer for printing concave-convex effect layers is installed between the second and third conveyor belts. Ink printer; the working planes of the first and second flatbed inkjet printers are at the same height as the conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com