Health real-time monitoring system used for operation and rotation equipment

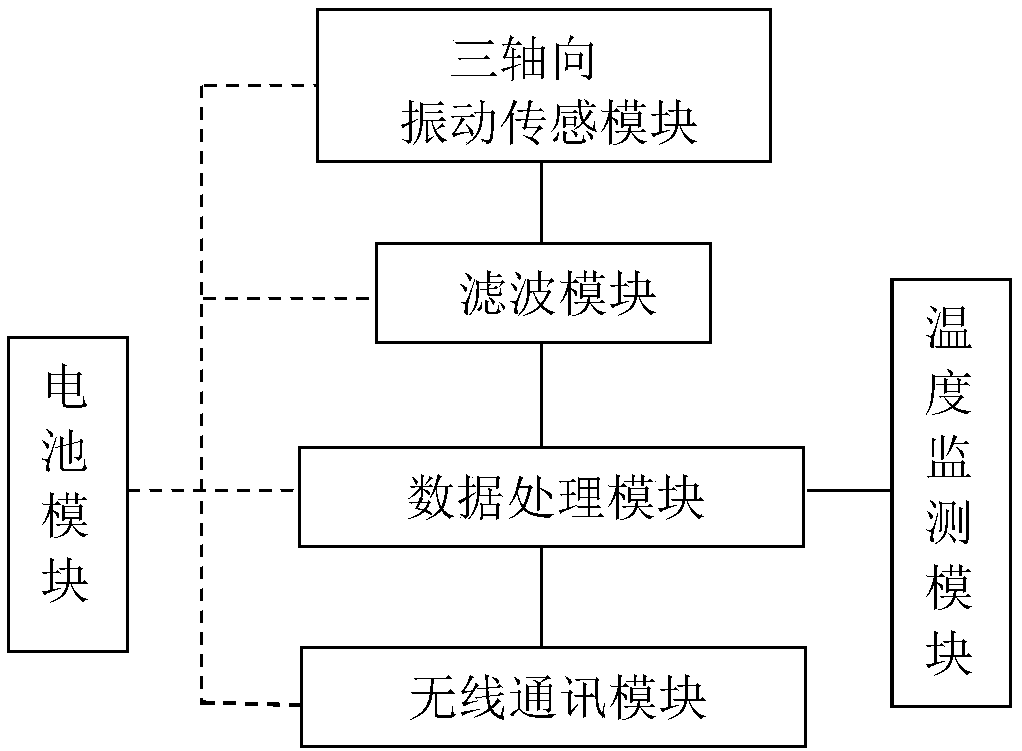

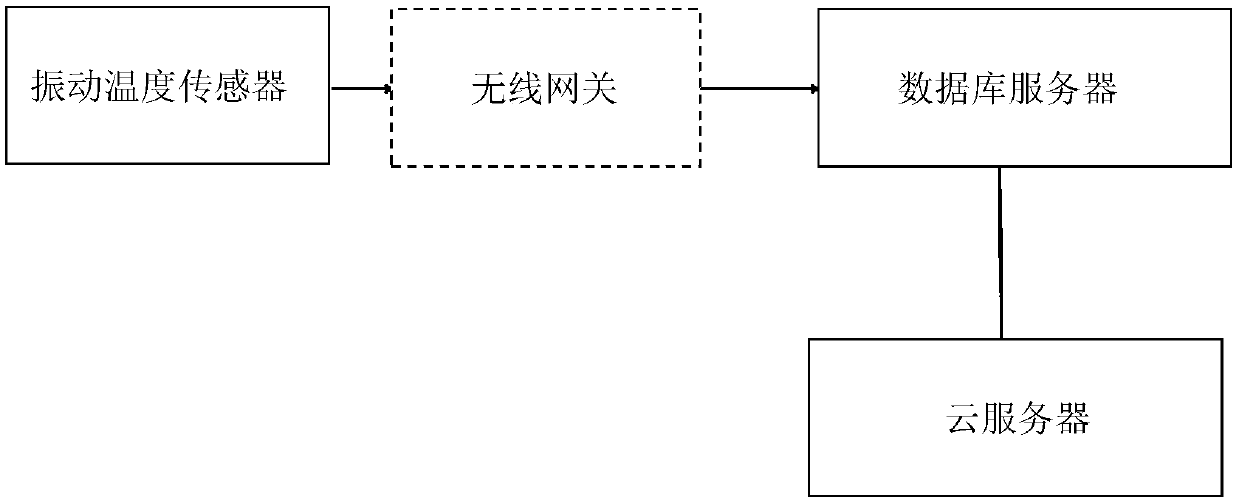

A technology for real-time monitoring systems and equipment, applied in signal transmission systems, measuring devices, measuring heat, etc., can solve problems such as systems without operating equipment health monitoring, shortening the normal life of bearings, and accelerating motor bearing wear, etc. The effect of data storage and fault diagnosis, reducing major accidents and extending operating life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the purpose, technical solution and advantages of the present invention more clear, further detailed description will be made in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

[0041] First of all, it needs to be explained that the present invention belongs to signal detection technology and relates to the application of computer technology in the field of industrial production. During the implementation of the present invention, the application of multiple software function modules will be involved. The applicant believes that, after carefully reading the application documents and accurately understanding the realization principle and purpose of the present invention, combined with existing known technologies, those skilled in the art can fully implement the present invention by using their software ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com