Three-dimensional chromatographic separation system on basis of two-position ten-way valve

A chromatographic separation and ten-way valve technology, applied in the direction of material separation, analysis materials, measuring devices, etc., can solve the problem of impurity and multi-flow equalization after reverse elution, and achieve the effect of reducing the total separation time and improving the separation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

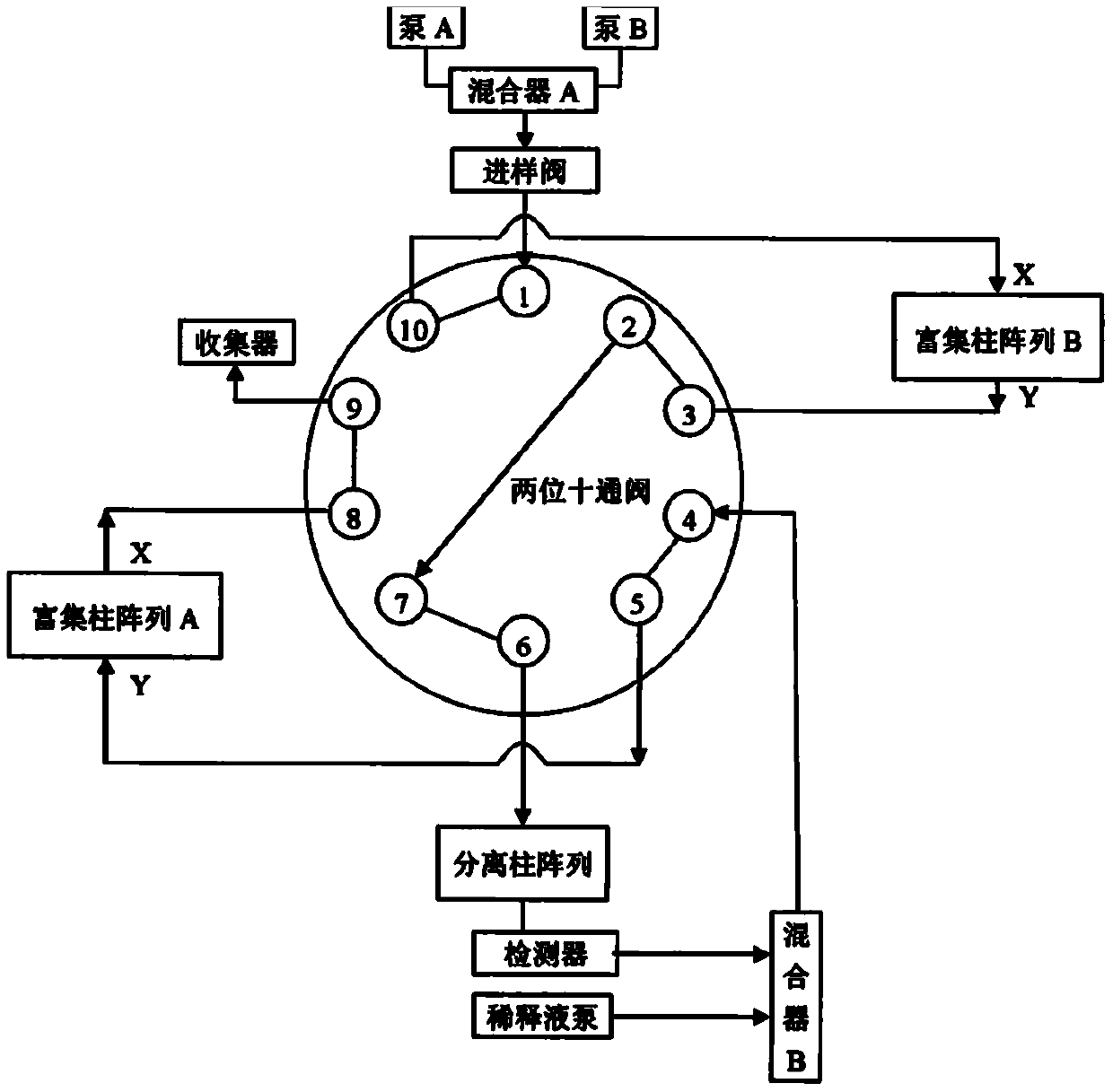

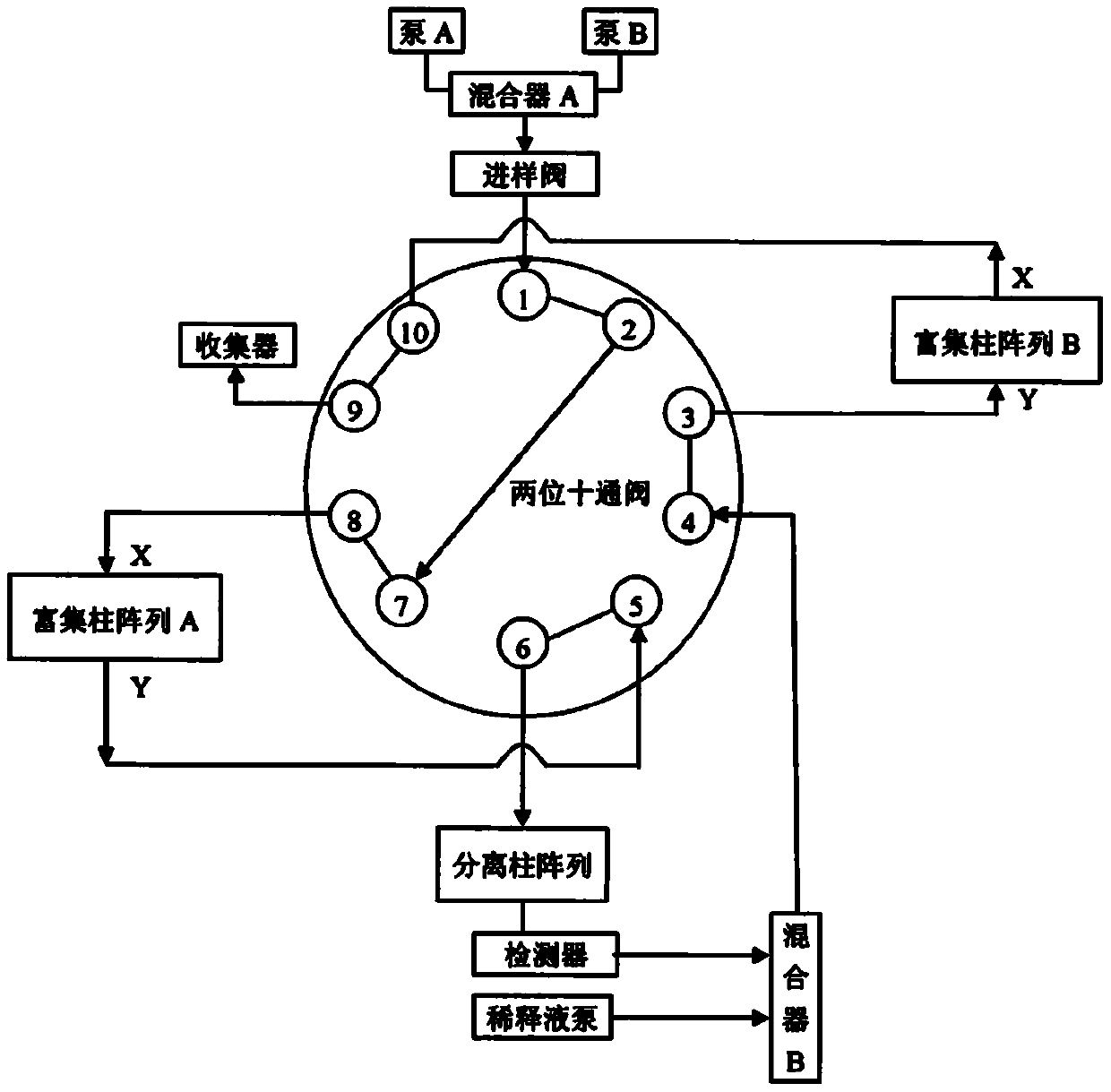

[0034] Embodiment: A kind of three-dimensional high performance liquid chromatography separation system structure

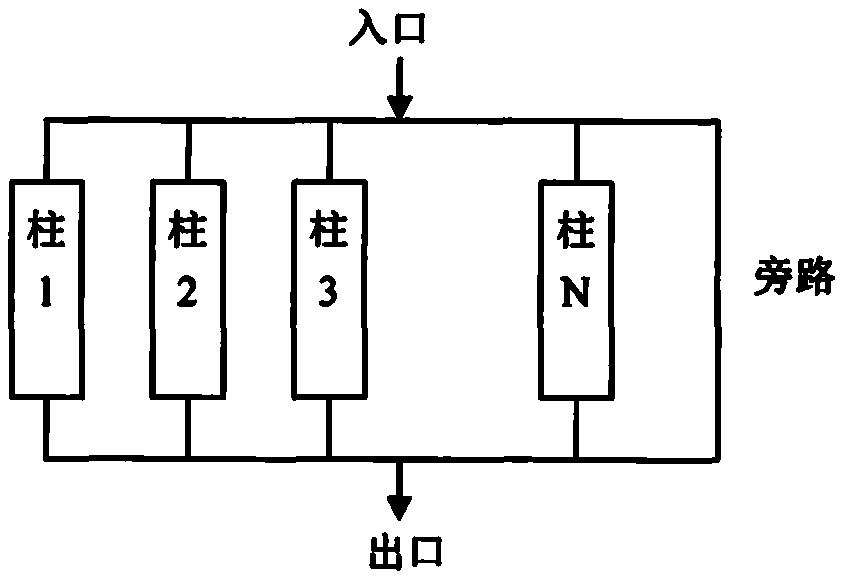

[0035] In this embodiment, the enrichment column array B has 9 enrichment columns, which are sequentially numbered as the first enrichment column of the enrichment column array B, the second enrichment column, etc., and the last number is the column of the enrichment column array B. The ninth enrichment column; the enrichment column array A is a two-stage enrichment column array, and each enrichment column array has 9 enrichment columns, that is, the enrichment column array A has 18 enrichment columns, and the numbers are enrichment The first enrichment column of column array A, the second enrichment column, etc., the last number is the 18th enrichment column of enrichment column array A; the liquid chromatography separation column array has 5 separation columns, which are numbered sequentially The first separation column, the second separation column, etc., the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com