Automatic detecting device for selenium drum of printer

An automatic detection device, detection device technology, applied in the direction of measuring device, measuring device shell, workpiece clamping device, etc., can solve problems such as low efficiency, achieve the effect of improving detection efficiency, convenient detection, and improving positioning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

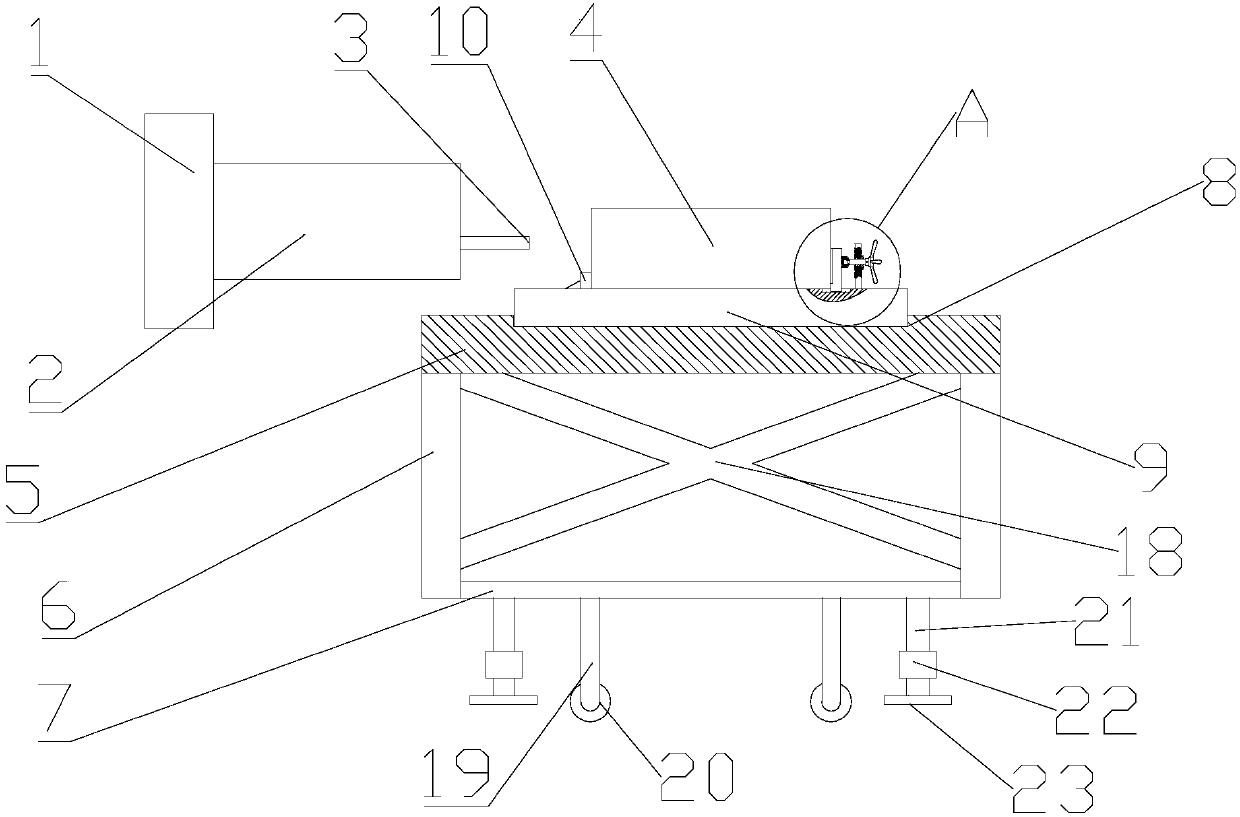

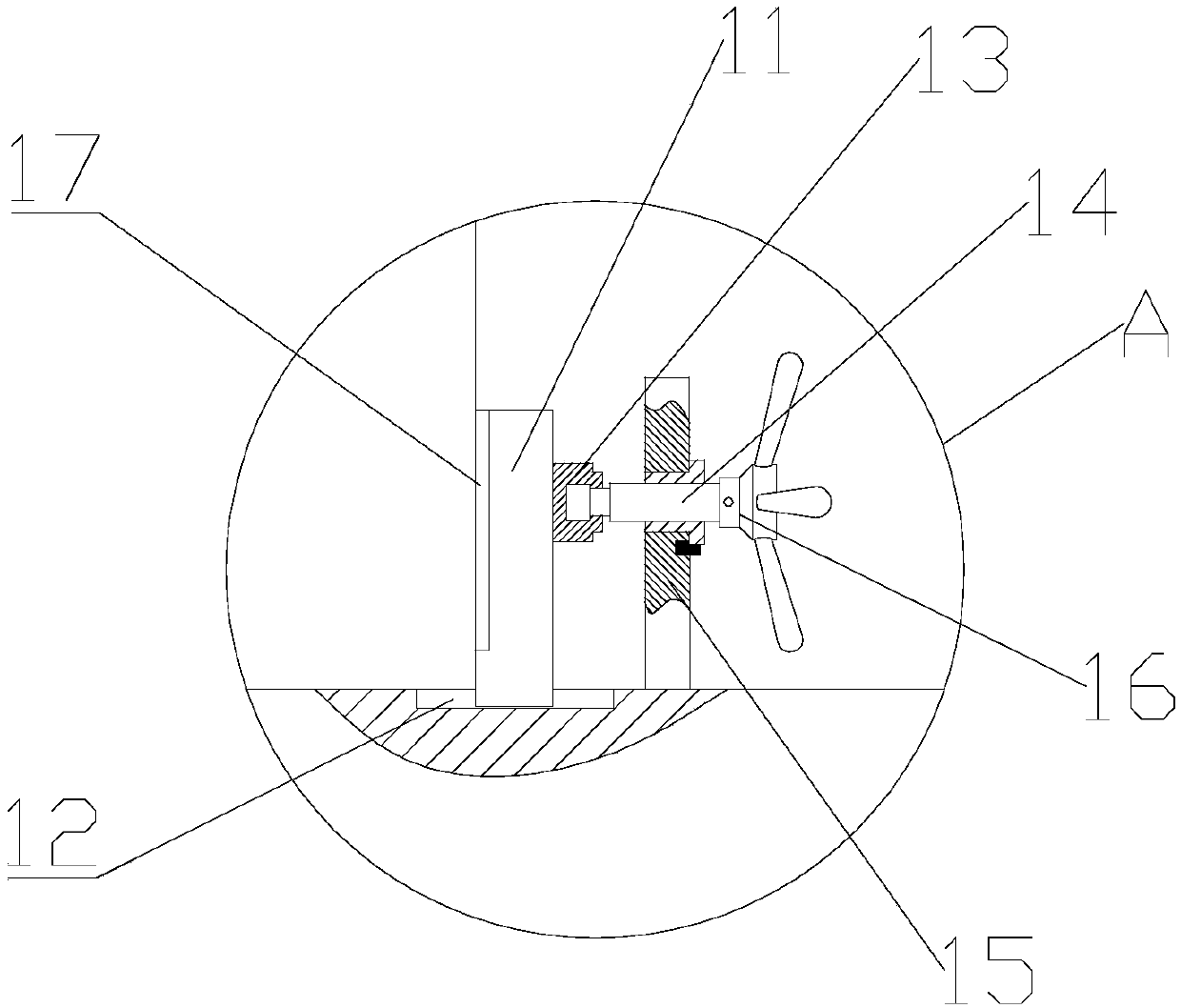

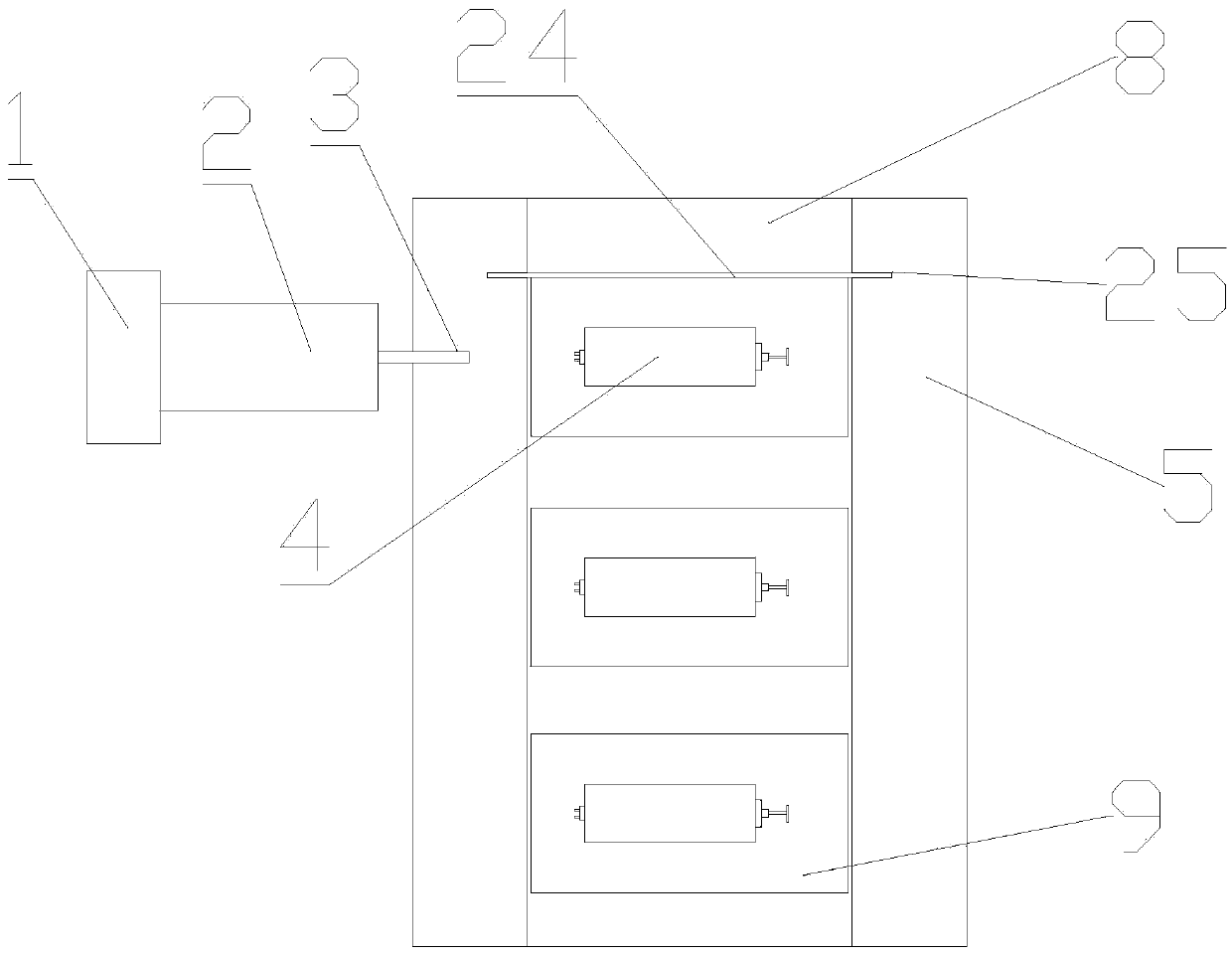

[0021] see figure 1 and figure 2 , an automatic detection device for a printer toner cartridge, comprising a hydraulic push rod 1, a detection device 2, a detection probe 3, a printer toner cartridge 4, a workbench 5, a support rod 6 and a bottom plate 7, and a detection device is installed on the right side of the hydraulic push rod 1 Device 2, the right side of the detection device 2 is provided with a detection probe 3, the right side of the detection probe 3 is provided with a printer toner cartridge 4, the printer toner cartridge 4 is installed on a workbench 5, and the lower end surface of the workbench 5 is The support rod 6 is fixed by welding, and the bottom end of the support rod 6 is welded and fixed on the base plate 7; the printer toner cartridge 4 is fixed on the mounting table 9 through the fixed baffle plate 10 and the dynamic pressure plate 11, and the number of the mounting table 9 is greater than one , the fixed baffle 10 is welded and fixed on the upper e...

Embodiment 2

[0023] see figure 1 and image 3 , the bottom surface of the bottom plate 7 is bolted with a wheel frame 19, and the wheel frame 19 is rotatably equipped with a universal wheel 20 to facilitate the movement of the device; The bottom end of the rod 21 is welded and fixed with a hydraulic cylinder 22, and the bottom end of the hydraulic cylinder 22 is welded and fixed with a support plate 23. When it moves to a suitable position, the hydraulic cylinder 22 pushes the support plate 23 down to lift the whole device, further improving The stability of the device; the workbench 5 is provided with a positioning plate slot 25, and the positioning plate 24 is installed in the positioning plate slot 25. When the mounting table 9 is close to the positioning plate 24, the mounting table 9 is fixed The toner cartridge 4 of the printer is just in the position aligned with the detection probe 3, which greatly improves the positioning speed and effectively improves the detection efficiency. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com