data-driven SPI defect type intelligent identification method on an SMT production line

A data-driven, intelligent recognition technology, applied in character and pattern recognition, instruments, calculations, etc., can solve problems such as false alarm rate, high false alarm rate, poor optimization effect, etc., to reduce parameter setting errors and improve detection efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

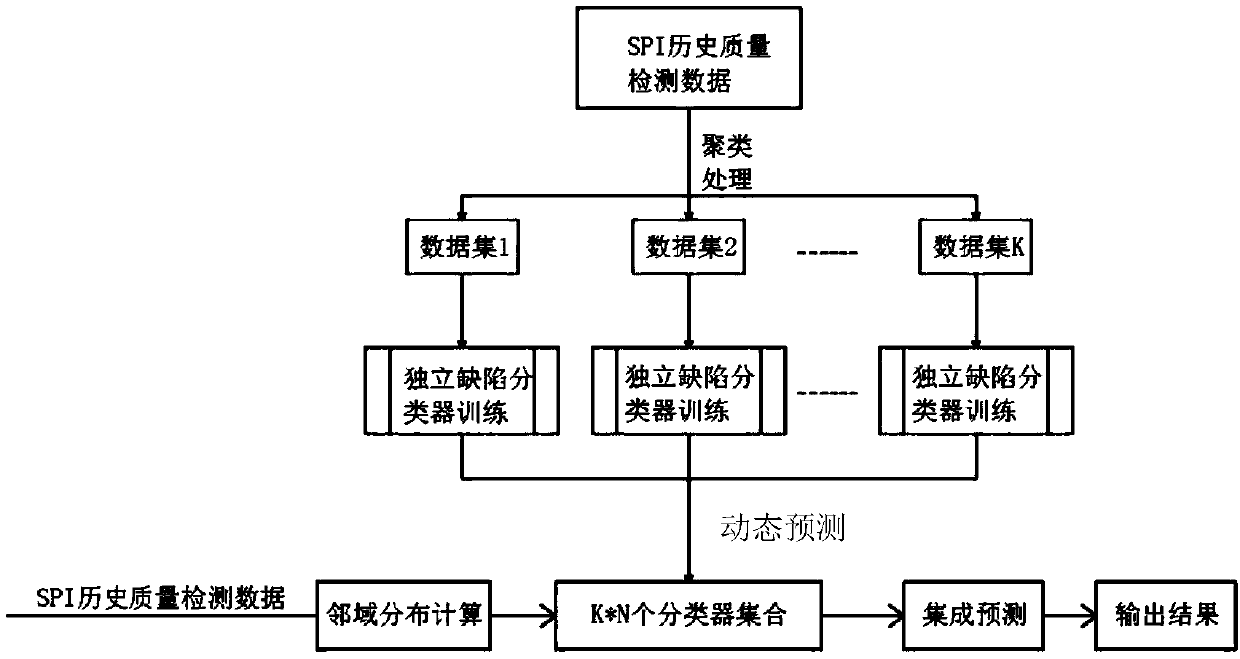

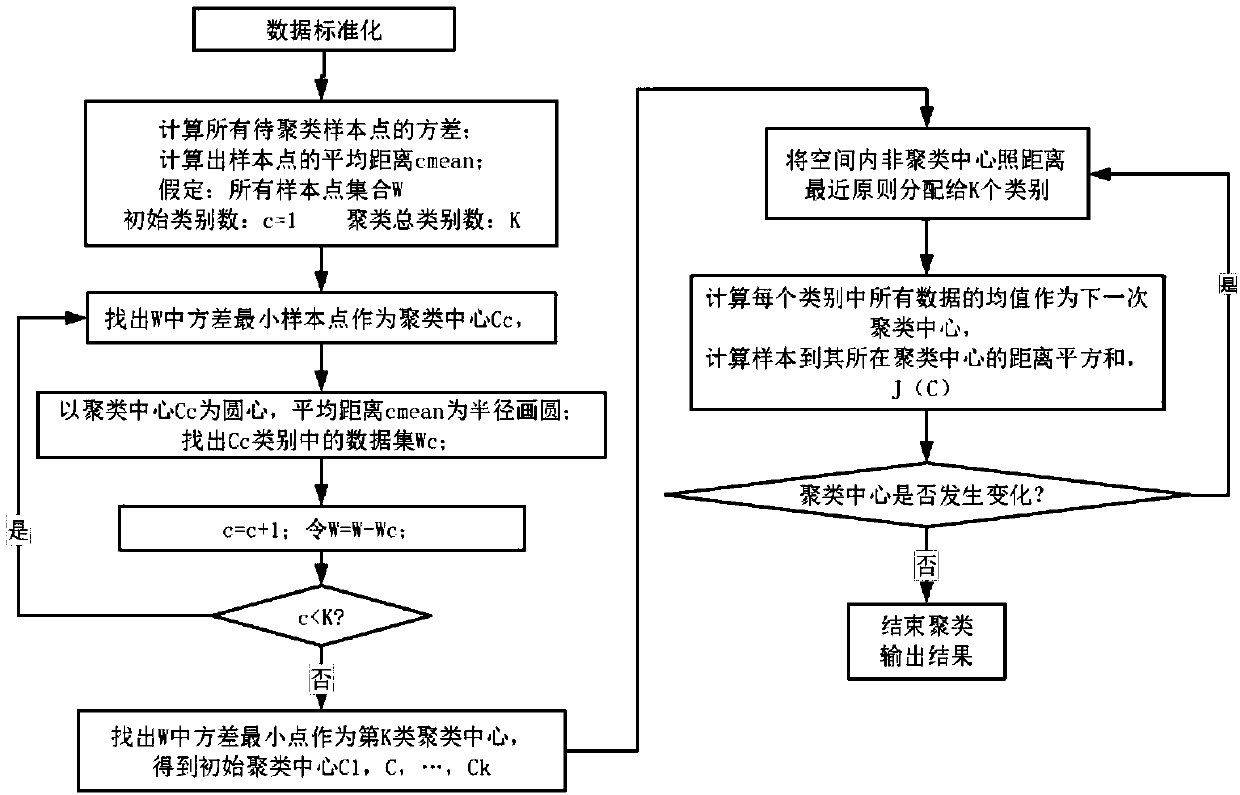

Method used

Image

Examples

Embodiment Construction

[0051] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

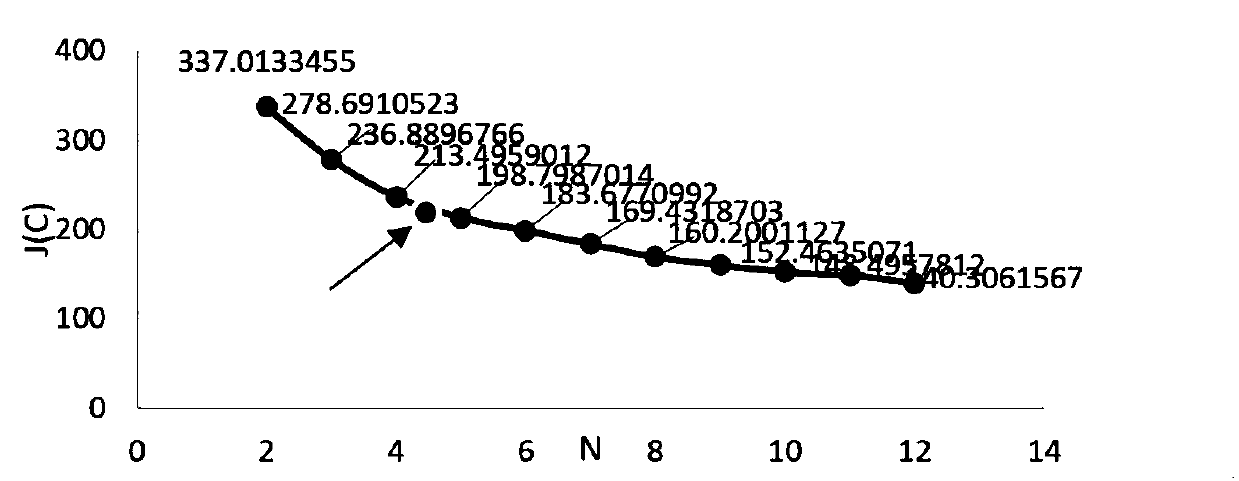

[0052]The single detection data record format and quality results of SPI detection on an SMT production line are shown in Table 1, and the defect categories and numbers of solder paste printing are shown in Table 2. Solder paste printing solder paste defects and defect types for more accurate automatic judgment. The quality inspection data used in this example is 18,703 pieces, including "32" pieces without solder paste and "4096" pieces of bridging defects that occur independently. The details are shown in Table 3. According to the process shown in the present invention, the 18703 is studied and model verified. The specific operation steps are as follows: Table 1 five example SPI detection records

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com