Method for removing a filler from a cavity present in a component and device for carrying out the method

A technology of components and cavities, applied in the field of equipment used to remove fillers from cavities existing in components and for performing this, can solve the problems of time-consuming powder, cannot be completely removed from cavities, etc., and achieve optimal movement The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

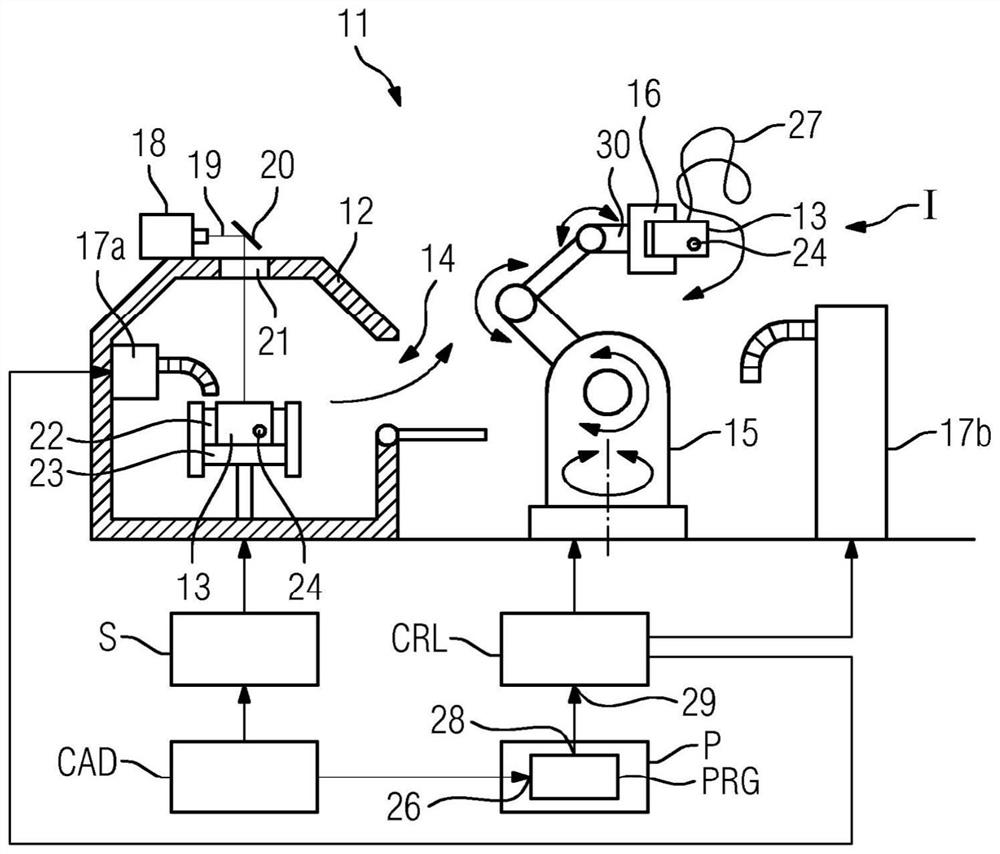

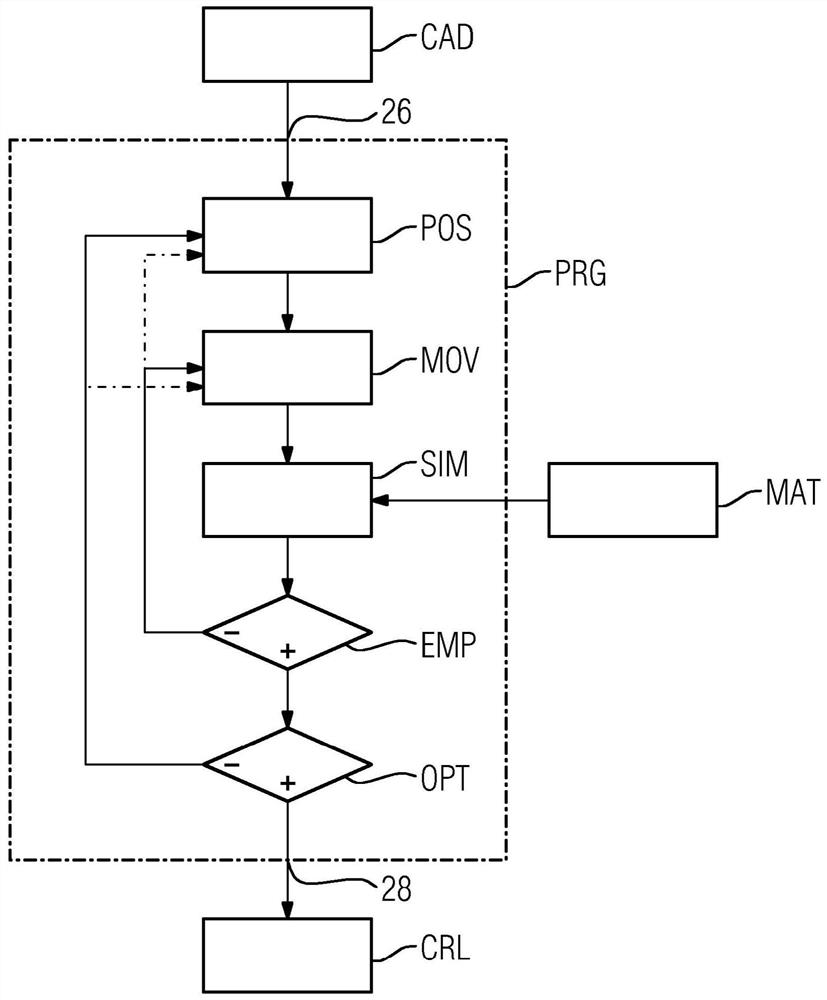

[0030] The manufacturing unit 11 has a device 12 for the additive manufacturing of components 13 , wherein this is a device for selective laser melting. The device has a material interface 14 in the form of a flap, through which components can be accommodated in a holder 16 by a robot 15 with four axes indicated by double-headed arrows. Furthermore, the production unit 11 has a plurality of suction devices 17a, 17b.

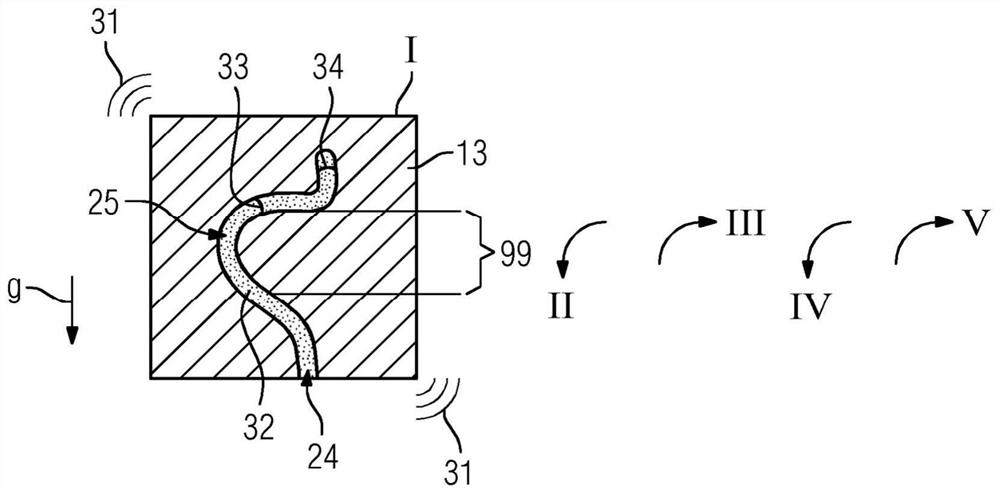

[0031] The structure of the apparatus 12 for selective laser melting is known and described in figure 1 are shown schematically only. The laser 18 generates a laser beam 19 which is directed by the steering optics 20 via the window 21 onto the powder bed 22 so that the component 13 is layered on the build platform 23 . After the production of the component 13 has been completed, the component 13 can first be exposed from the powder bed by means of the suction device 17a. In addition, some powder may have passed through the communication port 24 from the cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com