Double-rotor bidirectional variable displacement pump or motor

A two-way variable, double rotor technology, applied in the direction of variable displacement pump components, pumps, multi-cylinder pumps, etc., can solve the problems of small overall displacement, large unfavorable load, large friction loss, etc., to reduce friction energy loss, The effect of counteracting adverse loads and reducing system wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

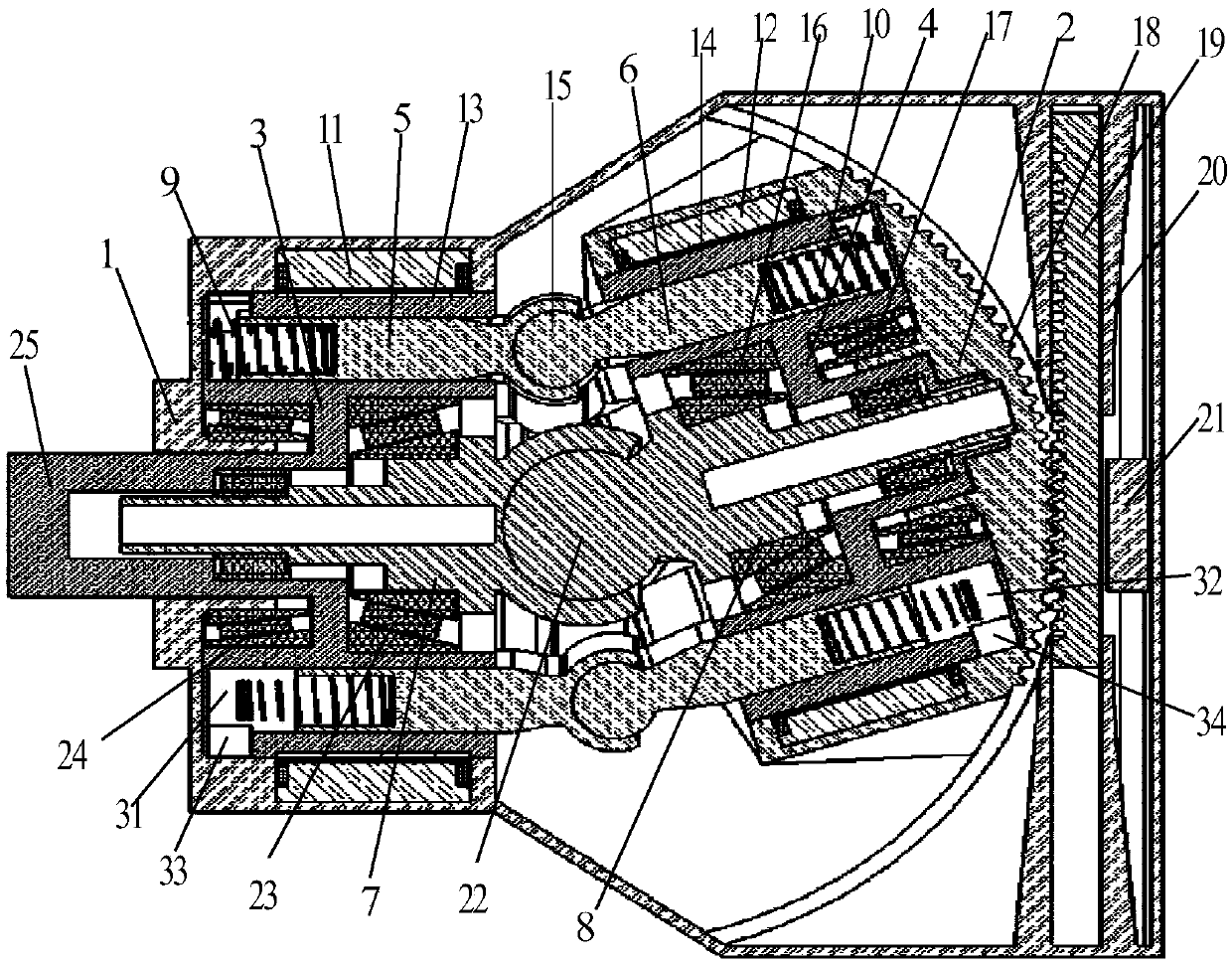

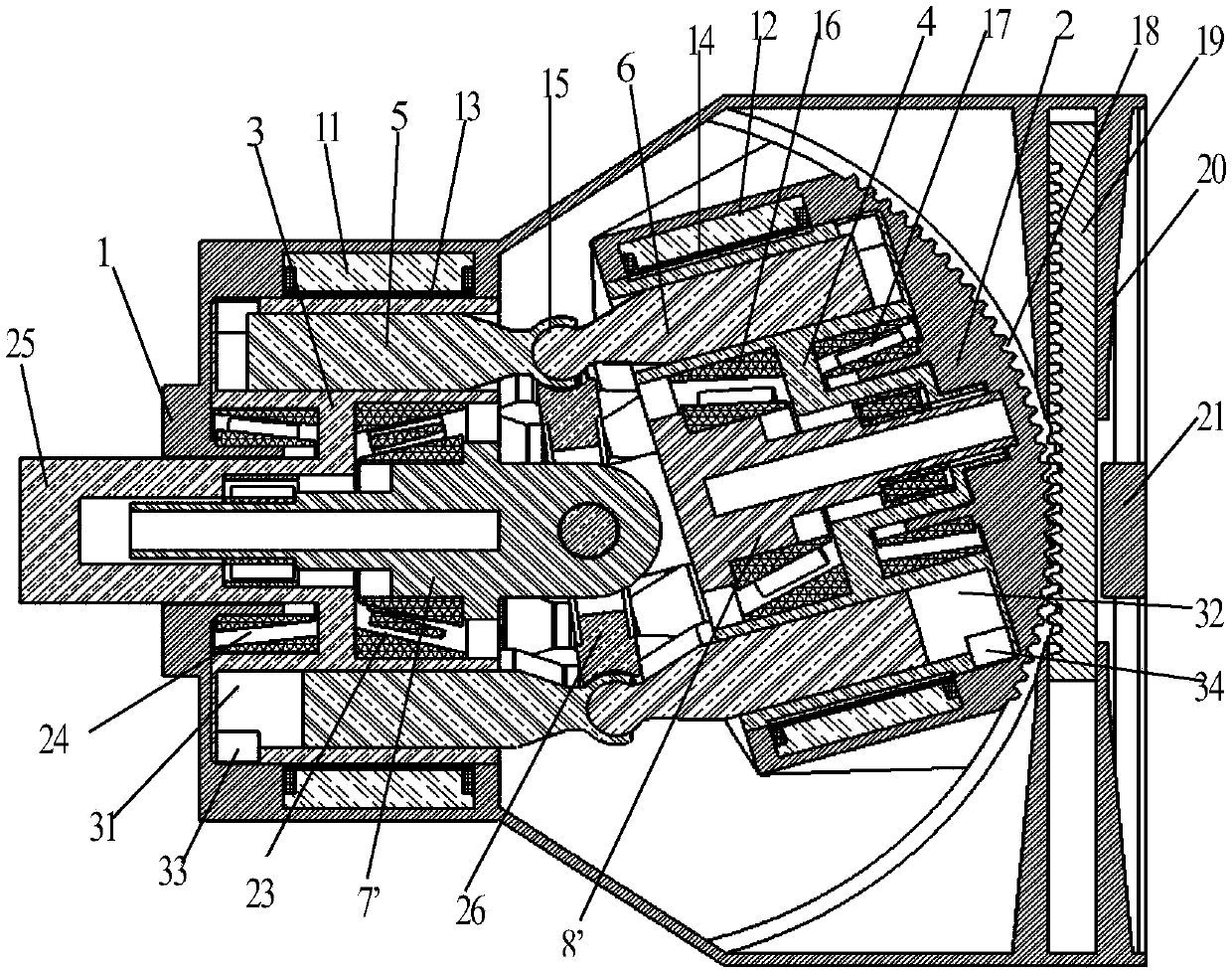

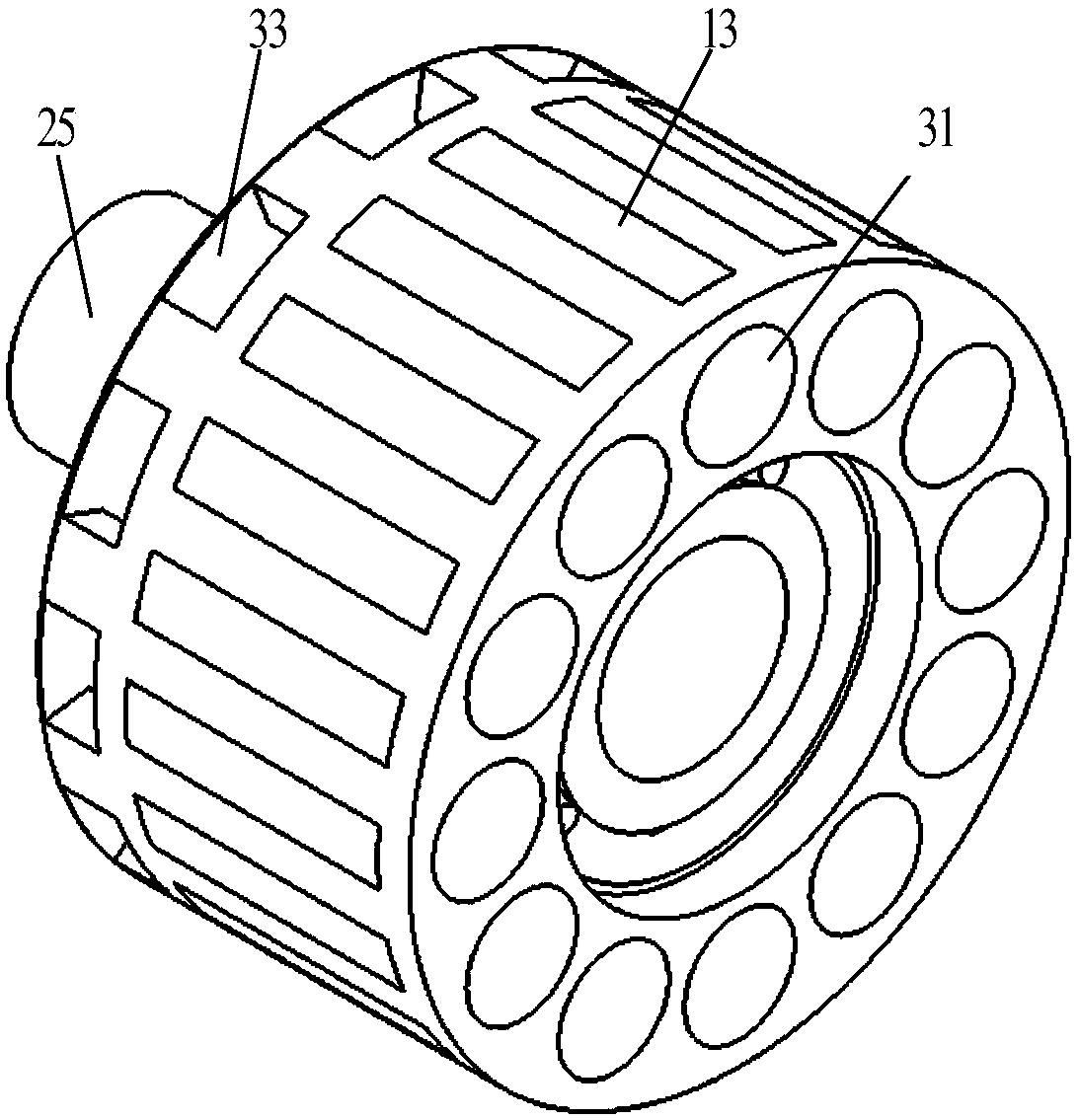

[0031] As shown in the figure, the dual-rotor bidirectional variable displacement pump or motor of the present invention includes a first base body 1 and a second base body 2, and the first base body 1 and the second base body 2 are respectively provided with a first accommodation chamber and a second accommodation chamber , the first rotor cylinder 3 and the second rotor cylinder 4 are rotatably arranged in the first accommodation chamber and the second accommodation chamber, and the first rotor cylinder 3 and the second rotor cylinder 4 are respectively A first plunger chamber 31 and a second plunger chamber 32 are provided eccentrically. As shown in the figure, the first rotor cylinder 3 and the second rotor cylinder 4 respectively pass through corresponding bearings (including angular contact bearings or thrust bearings, As shown in the figure, the angular contact bearings 24 and 17 are arranged on the corresponding first base body 1 and the second base body 2, and the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com