A vacuum heat collecting tube with helically advancing semi-circumferentially distributed fin bodies

A vacuum heat-collecting tube and half-circle technology, which is applied in the direction of solar heat collectors, solar heat collectors, and solar thermal energy using working fluids. Applicable to problems such as gas heat transfer fluid and fluid viscosity increase, to achieve the effect of promoting high-efficiency conversion, reducing temperature gradient, and optimizing flow field and temperature field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

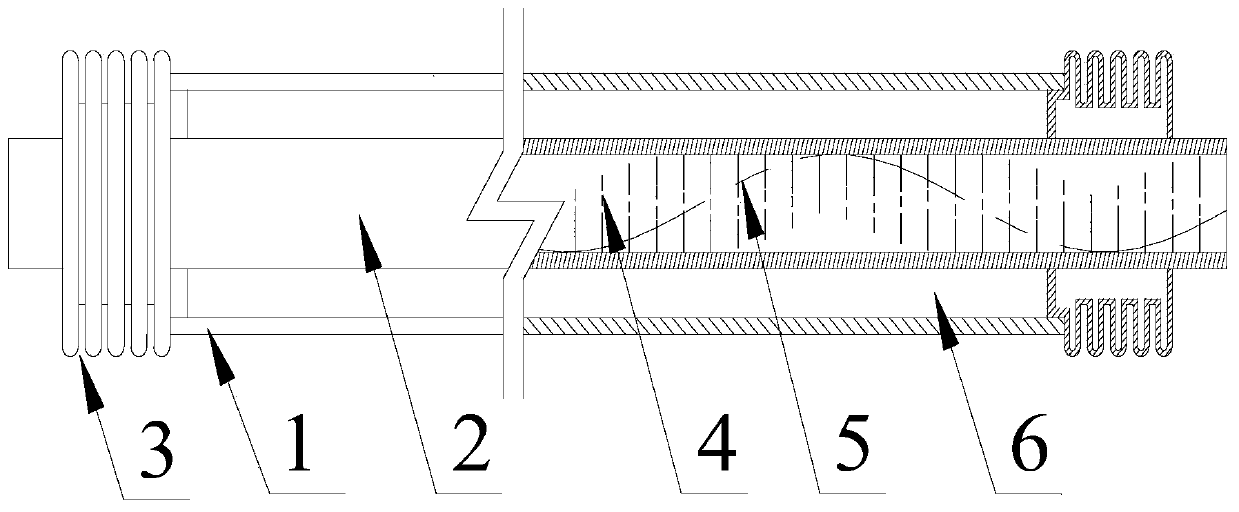

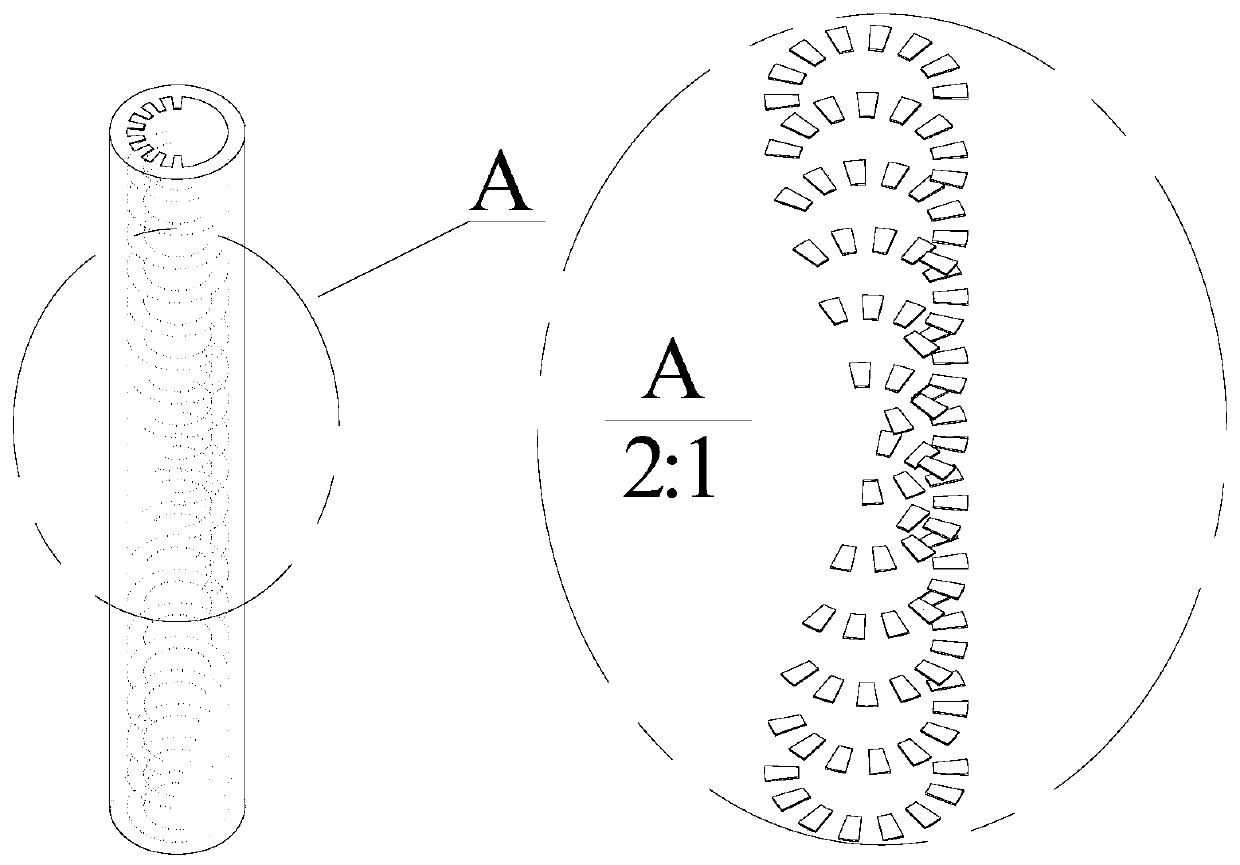

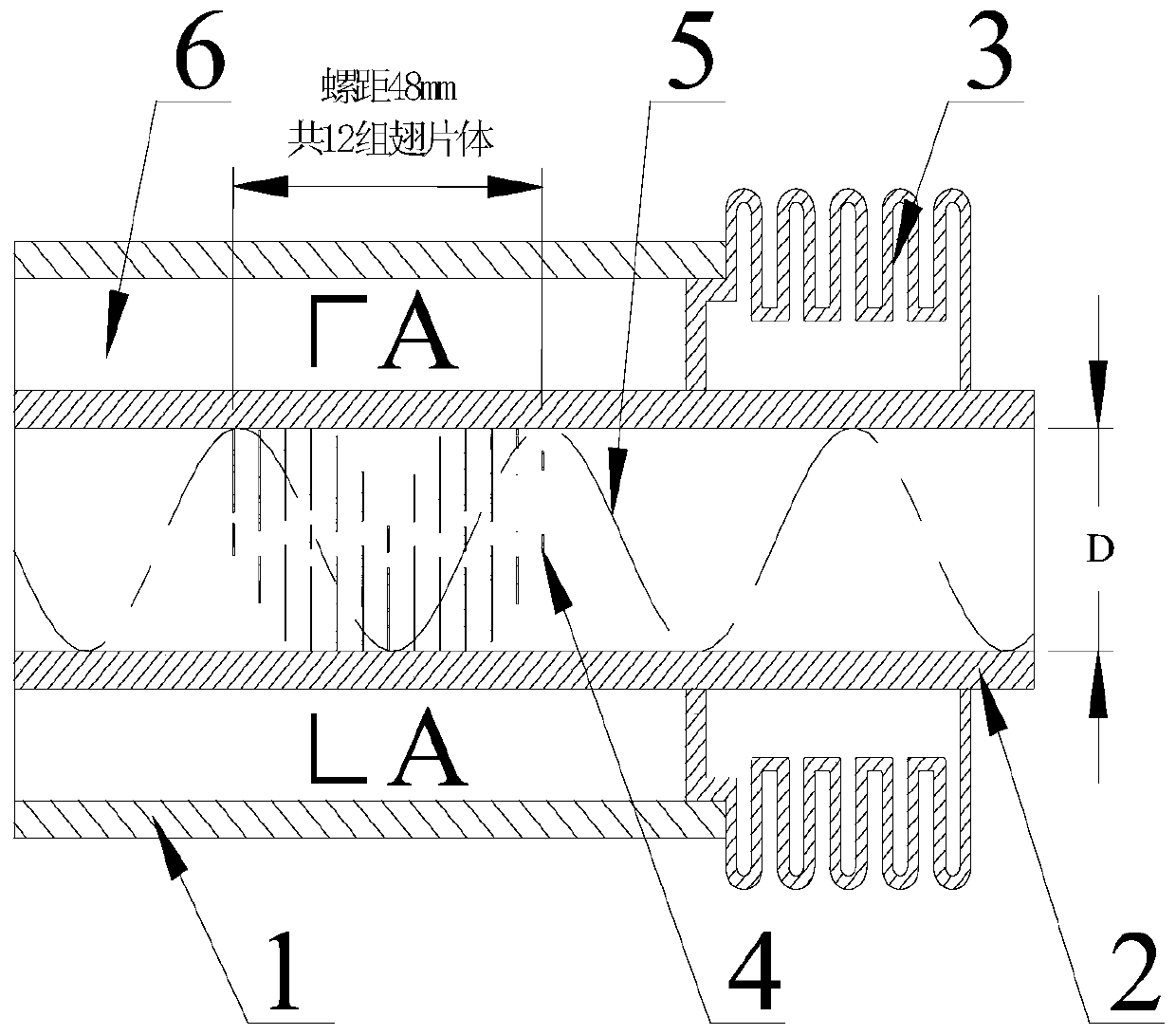

[0029] A vacuum heat-collecting tube with spirally advanced fins distributed on a semi-circumference, comprising a glass outer tube 1 and a metal heat-absorbing tube 2 containing fins 4, the metal heat-absorbing tube 2 is located in the glass outer tube 1, and Shaft arrangement. The glass outer tube 1 is connected with the metal heat absorbing tube 2 through a sealing device, and an expansion joint 3 is arranged at the end of the glass outer tube 1 . A vacuum cavity 6 is formed between the metal heat-absorbing tube 2 and the glass outer tube 1 . The schematic diagram of the distribution of fins in the metal heat absorbing tube is as follows: figure 2 shown.

[0030] One of the embodiments of the heat collecting tube of the present invention is as image 3 shown. The outer wall of the metal heat-absorbing pipe 2 is coated with a selective ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com