An automobile back door electric stay bar torque optimization method

A technology for automobile back doors and electric struts, applied in design optimization/simulation, electrical digital data processing, instruments, etc., can solve problems such as poor performance of electric struts, and achieve the effect of improving performance and improving design capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

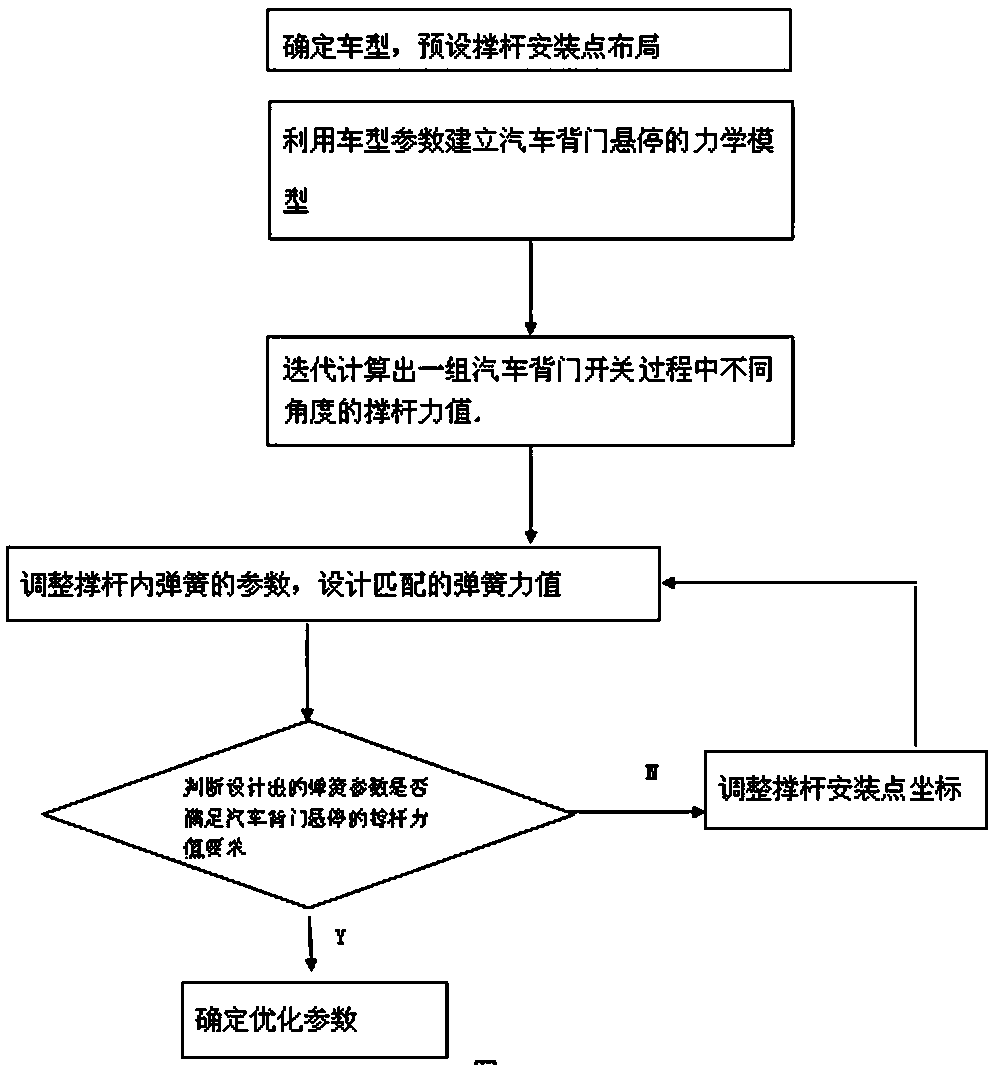

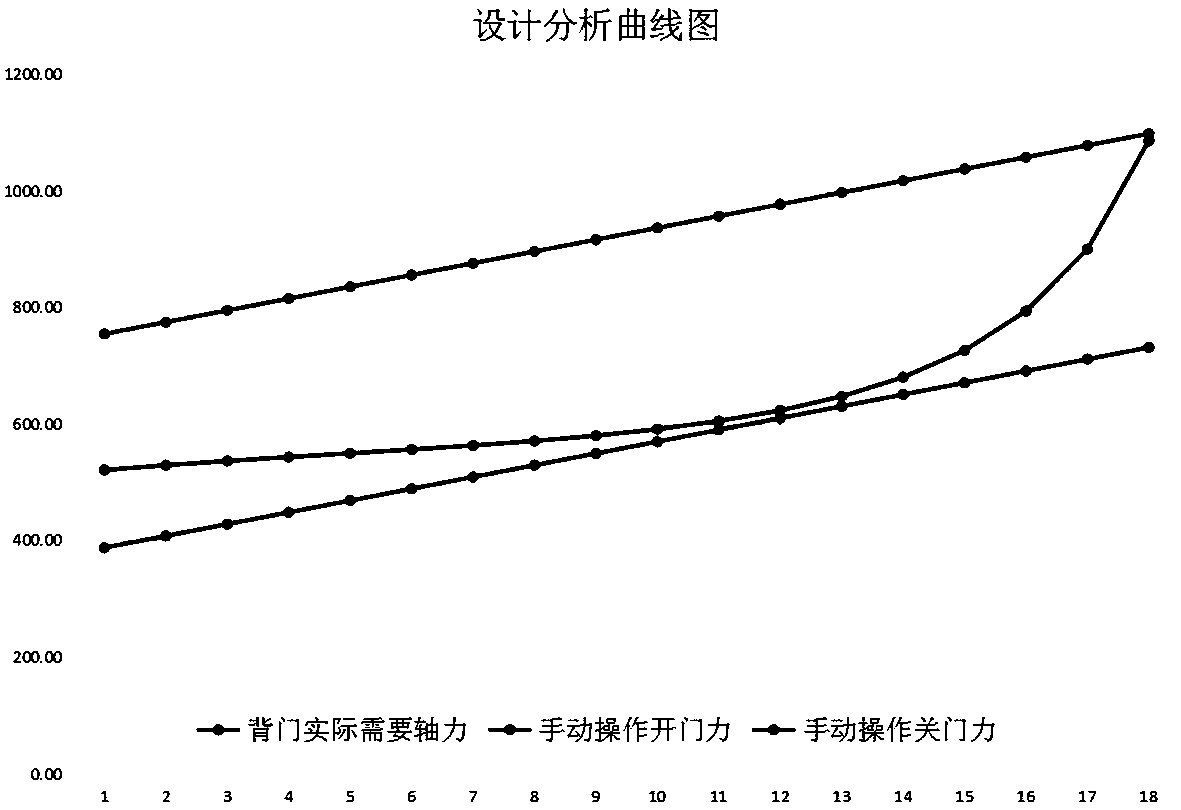

[0021] figure 1 The shown method for optimizing the torque of the electric strut for the back door of the automobile includes the following steps:

[0022] Step S1: The car model optimized in this embodiment is the V302 car model, and the layout of the strut installation points of this car model is preset;

[0023] Step S2: Use the vehicle model parameters to establish a mechanical model of the car's back door hovering, and calculate the moment arm of the center of gravity of the back door to the center of rotation of the back door hinge and the moment arm of the strut to the center of rotation of the back door hinge; the calculation formula is:

[0024] L 背 =X M -X O

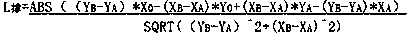

[0025]

[0026] Among them, L 背 is the moment arm between the center of gravity of the back door and the center of rotation of the back door hinge, L 撑 The moment arm of the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com