Display panel and manufacturing method thereof

A technology for a display panel and a manufacturing method, which is applied in the direction of electrical components, electric solid-state devices, circuits, etc., and can solve problems affecting the position accuracy of light-emitting diodes, offset of light-emitting diodes, and poor display quality, so as to reduce light leakage and mixed light The effect of reducing precision tolerance and increasing light efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

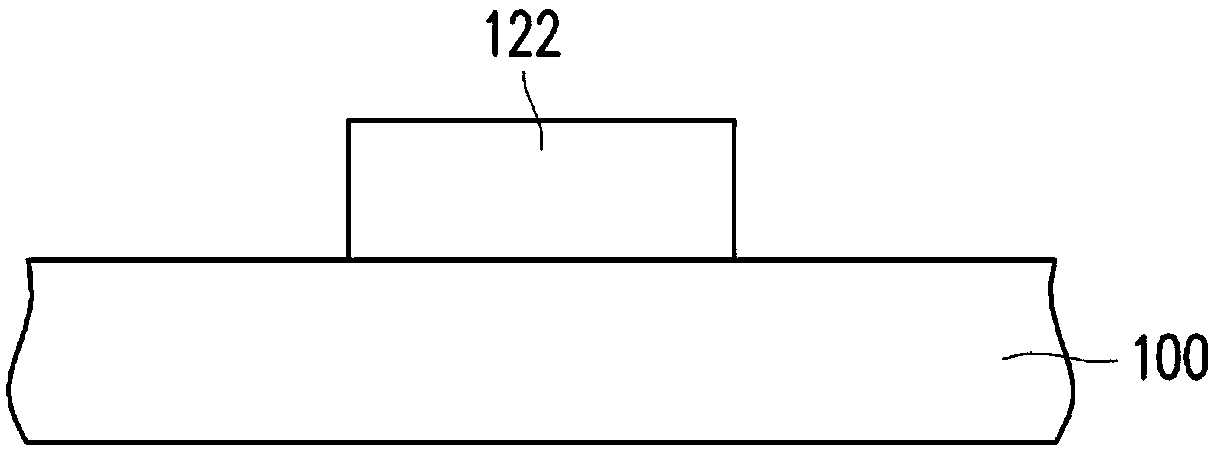

[0053] The present invention will be described more fully below with reference to the accompanying drawings of this embodiment. However, the present invention can also be embodied in various forms and should not be limited to the embodiments described herein. The thicknesses of layers and regions in the drawings are exaggerated for clarity. The same or similar reference numerals denote the same or similar elements, and the following paragraphs will not repeat them one by one. In addition, the directional terms mentioned in the embodiments, such as: up, down, left, right, front or back, etc., are only directions referring to the attached drawings. Accordingly, the directional terms are used to illustrate and not to limit the invention. In addition, similar or identical element symbols are used in each figure to indicate similar or identical elements or features, and if there is an element symbol that is the same as that in the previous figure, its repeated description will be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com