Aqueous organic flow battery electrolyte, preparation method thereof and aqueous organic flow battery

A flow battery and organic electrolyte technology, applied in the field of aqueous organic flow battery electrolyte and aqueous organic flow battery, can solve the problems of poor water solubility of products, limited application, increased battery cost, etc., to avoid chemical modification modification, The effect of improving solubility and improving energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038]The present application also provides a method for preparing an electrolyte for an aqueous organic liquid flow battery, comprising the following steps:

[0039] The organic electrolyte and coating are added to the supporting electrolyte solution to obtain an electrolyte solution; the coating is a cyclic molecule with a hydrophilic outer edge, a hydrophobic inner cavity and a cavity, and the organic electrolyte itself is poorly water-soluble or An electrolyte with poor water solubility after gaining and losing electrons.

[0040] In the above-mentioned process of preparing the electrolyte solution, the organic electrolyte, the coating, and the supporting electrolyte solution are mixed to obtain an electrolyte solution comprising an electrolyte composite in which the organic electrolyte is coated with the coating and a supporting electrolyte solution.

[0041] The above-mentioned raw material organic electrolyte, coating and supporting electrolyte solution have been descri...

Embodiment 1

[0047] Weigh 0.584g NaCl in a beaker, add 10mL deionized water, stir to dissolve; weigh 0.186g Fc and add it to the beaker, Fc is insoluble in water; weigh 4.625g hydroxypropyl-β-cyclodextrin (HP-β- CD) was added into a beaker, and stirred until Fc was completely dissolved, and then an aqueous organic flow battery anode electrolyte in which Fc was coated with 3 times HP-β-CD could be prepared. Due to the increase in solution volume due to the addition of cyclodextrin, its concentration is less than 0.1MFc, 0.3M HP-β-CD, 1M NaCl.

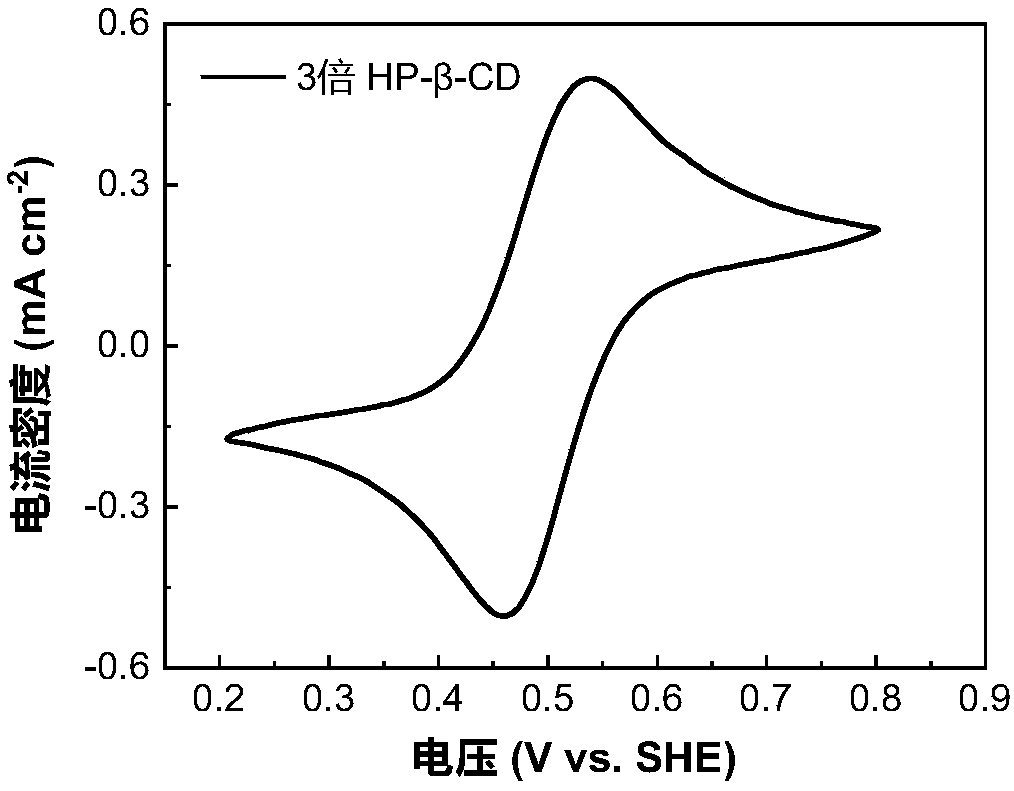

[0048] figure 1 yes (3 times) The cyclic voltammogram of the electrolyte, in which a pair of redox peaks at 0.50V vs. SHE corresponds to a single-electron redox reaction.

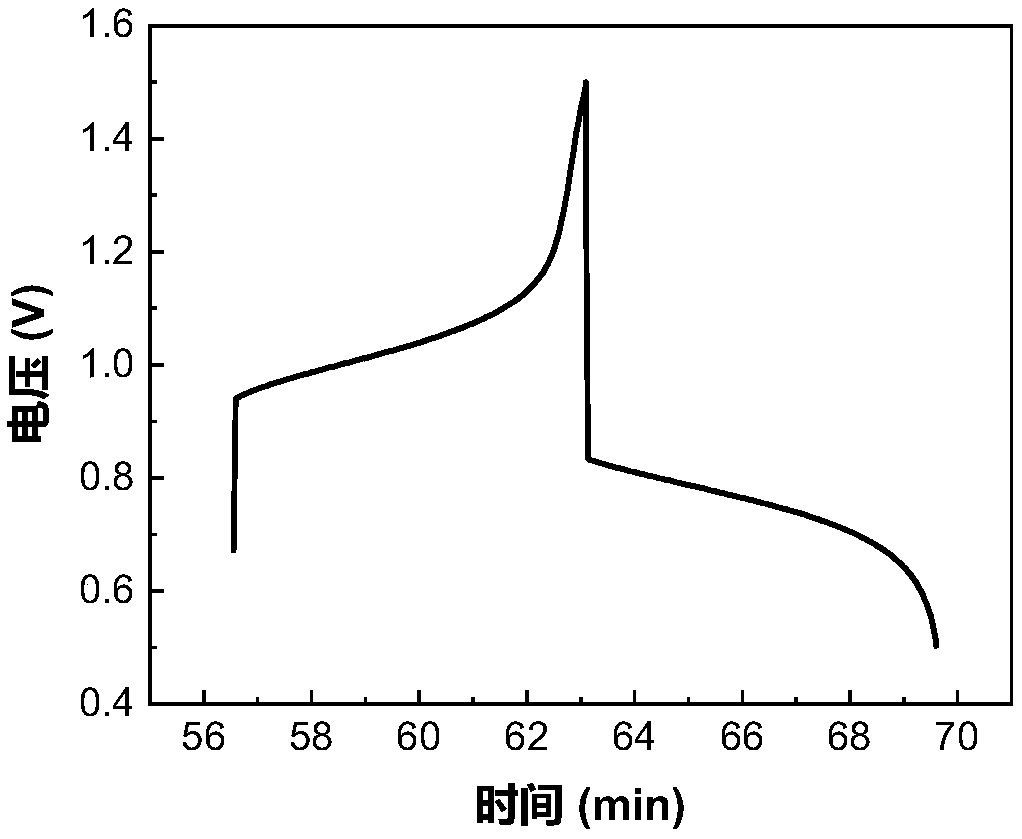

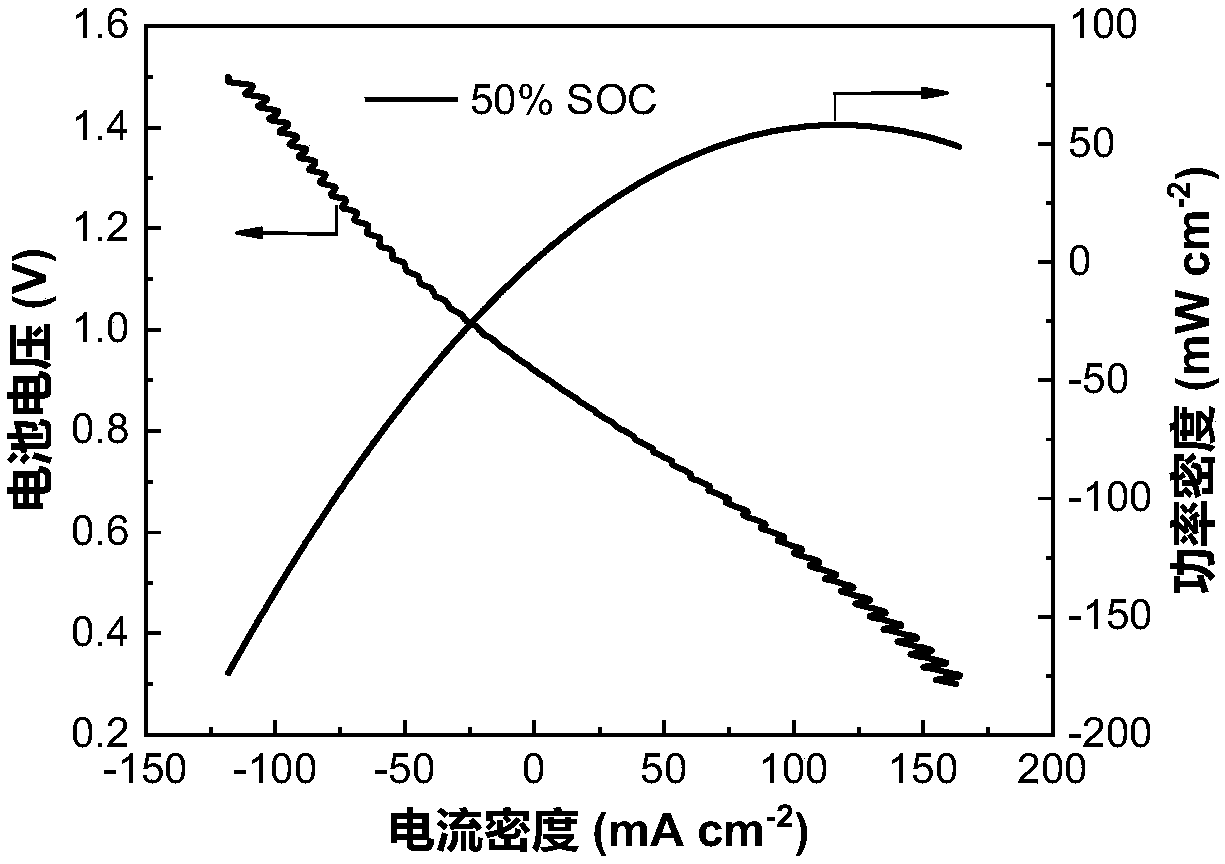

[0049] The Fc obtained in Example 1 is used to coat the positive electrolyte of the aqueous organic flow battery with 3 times HP-β-CD and BTMAP-Vi to form a flow battery. The speed of the peristaltic pump is 60rpm, and the positive and negative electrodes of the battery are bot...

Embodiment 2

[0052] Weigh 0.584g NaCl in a beaker, add 10mL deionized water, stir to dissolve; weigh 0.186g Fc, Fc is insoluble in water; weigh 6.167g HP-β-CD and add it to a beaker, stir until Fc is completely dissolved, then you can Aqueous organic flow battery cathode electrolyte with Fc coated on 4 times HP-β-CD was prepared. Due to the increase in solution volume due to the addition of cyclodextrin, its concentration is less than 0.1MFc, 0.4M HP-β-CD, 1M NaCl.

[0053] The Fc obtained in Example 2 is used to coat the positive electrode electrolyte of the water-based organic flow battery with 4 times HP-β-CD and BTMAP-Vi to form a flow battery. The speed of the peristaltic pump is 60rpm, and the positive and negative electrodes of the battery are both effective Area is 5cm 2 Carbon paper, the positive and negative electrodes are separated by an anion exchange membrane. Figure 6 yes (4 times) / BTMAP-Vi flow battery at 40mA / cm 2 The charge and discharge test curve graph under the cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com