Control method and control device used for integrated cooker and integrated cooker

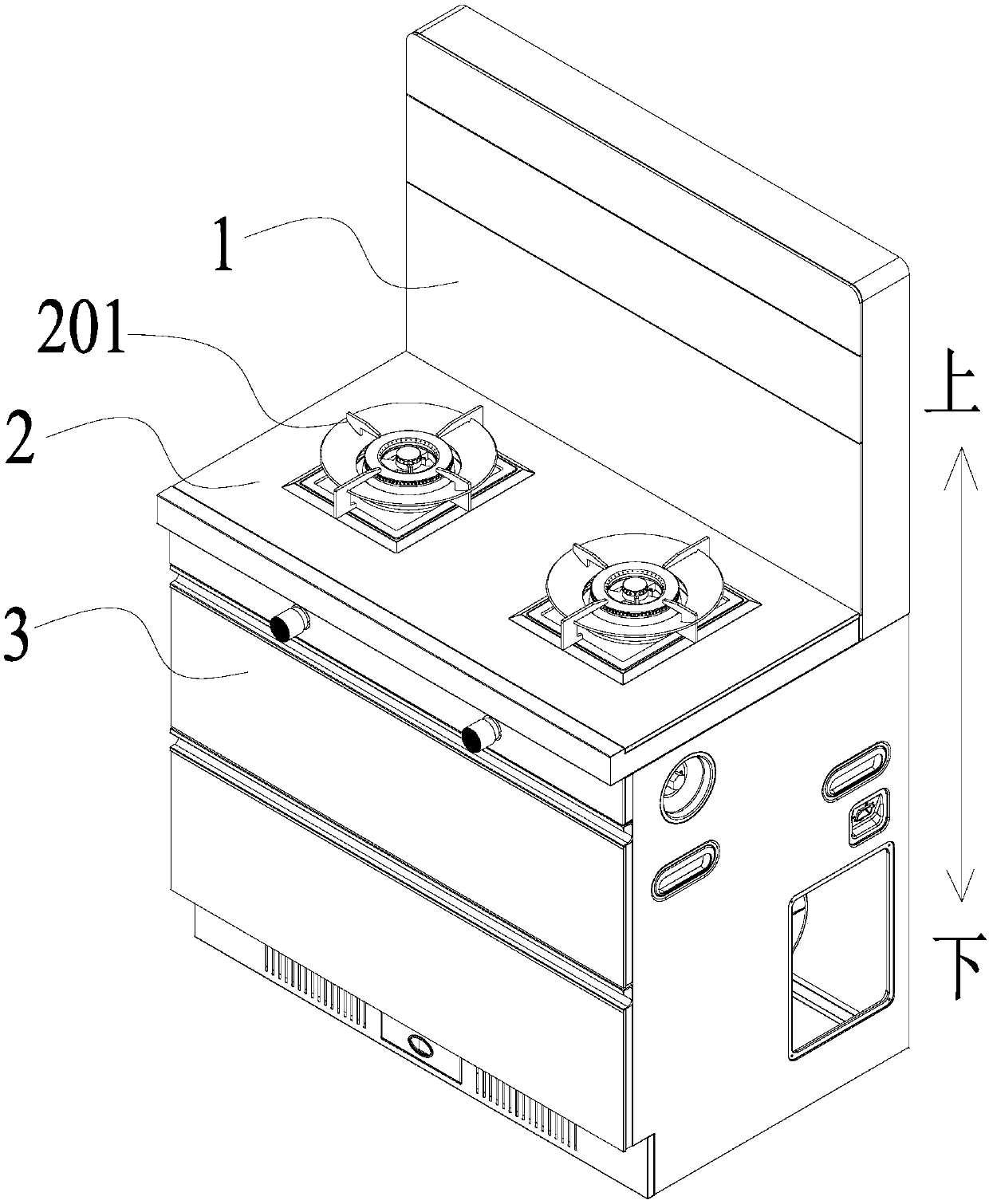

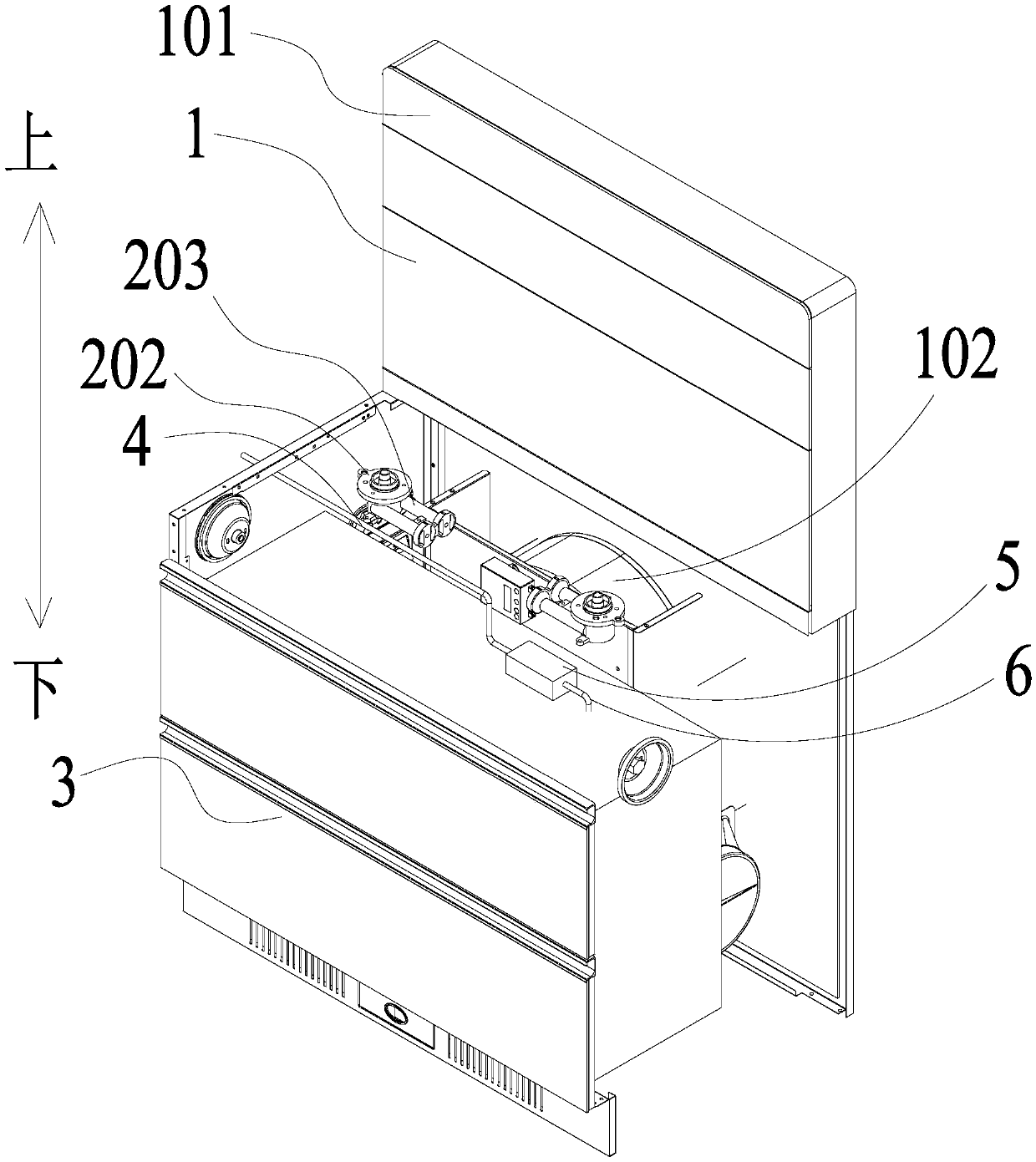

A technology of a control device and a control method, which is applied in the field of integrated stoves and can solve problems such as unreasonable disinfection and sterilization methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0071] Further, based on the first embodiment of the above-mentioned control method, the second embodiment of the control method further includes:

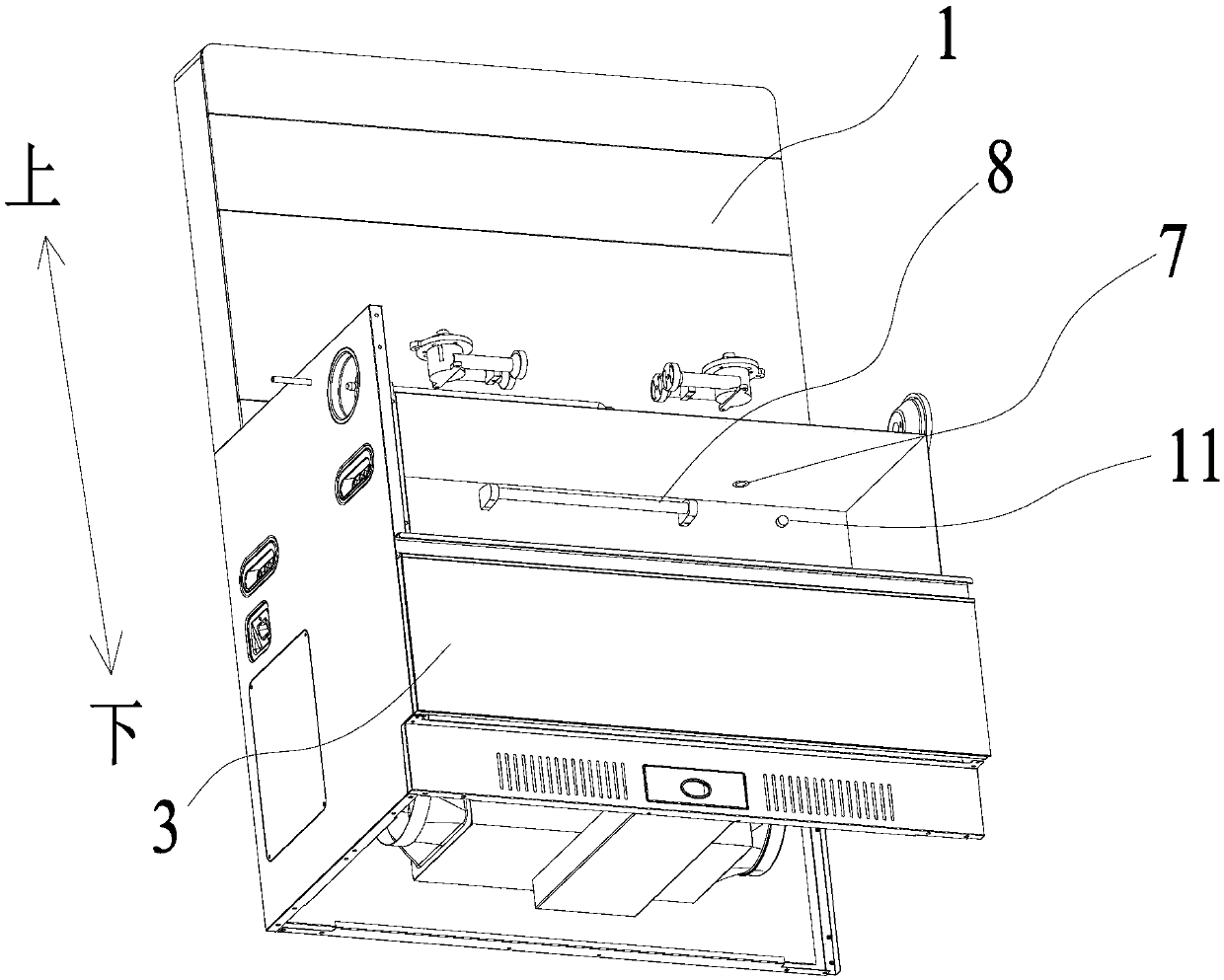

[0072] Before delivering the heated water vapor to the sterilization cabinet 3, the sterilization cabinet 32 is heated and the temperature inside the sterilization cabinet 3 reaches a first preset temperature.

[0073] That is, before the sterilization cabinet 3 is steam sterilized, the interior of the sterilization cabinet 3 is preheated. At this time, it can be preheated by the operation of the heater 8 arranged inside the sterilization cabinet 3 . A temperature and humidity sensor 11 can be set in the disinfection cabinet 3 to detect the internal temperature, and the preheating process is completed when the temperature reaches a first preset temperature such as 60°C. Adding a preheating process before steam sterilization can improve the sterilization effect.

[0074] Further, in the above step S520, it also includes: when t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com