Glue application machine for box sealing adhesive tapes

A gluing machine and adhesive tape technology, applied in coatings, devices for coating liquid on the surface, etc., can solve the problems of high cost and slow manual gluing efficiency, and achieve improved production efficiency, reduced production costs, and increased reset speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

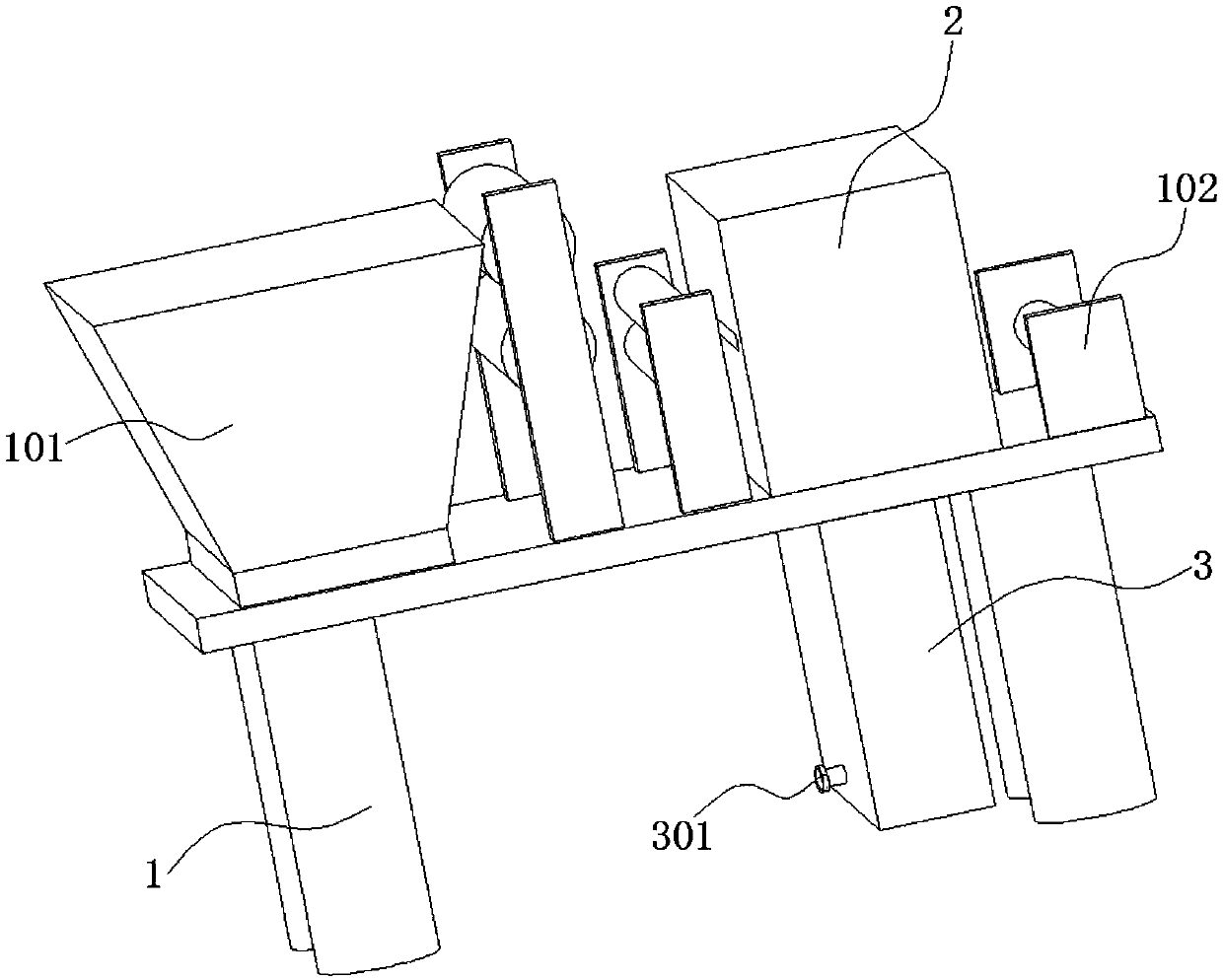

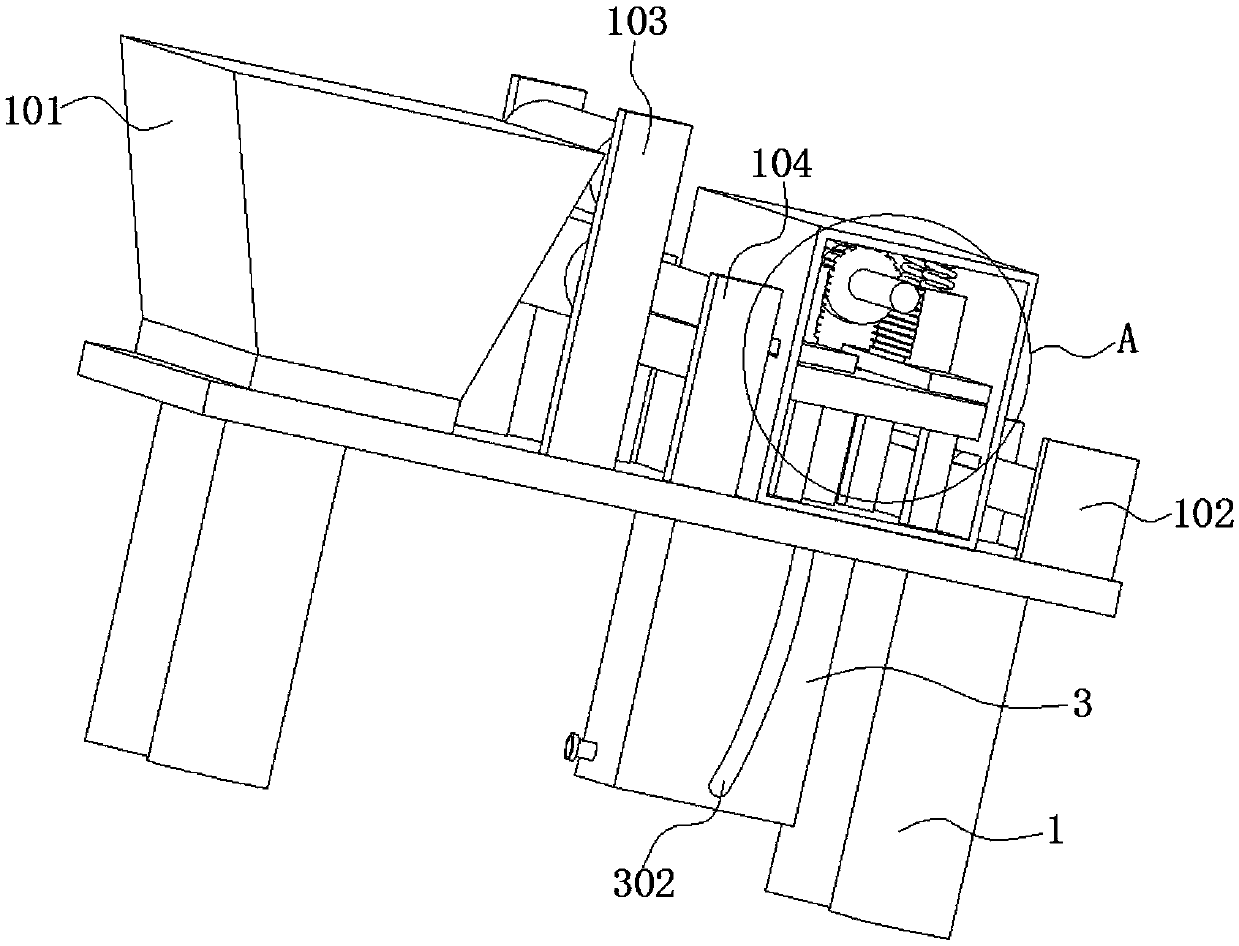

[0034] refer to Figure 1-4 , a sealing tape gluing machine, comprising a base 1, a film-making box 101, a first roller set 103 and a second roller set 104 are fixedly connected to the base 1, and an adhesive glue is fixedly connected to the base 1 Box 2, a first extruding plate 201 and a second extruding plate 202 are slidingly connected in the viscose box 2, a third extruding plate 207 is fixedly connected in the viscose box 2, and a drawer is fixedly connected on the bottom wall of the base 1. The liquid tank 3, the liquid inlet end of the liquid suction tank 3 is fixedly connected with the liquid inlet pipe 301, the liquid outlet end of the liquid suction tank 3 is fixedly connected with the liquid outlet hose 302, and the end of the liquid outlet hose 302 away from the liquid suction tank 3 is fixedly connected to the The upper end surface of the third extruding plate 207, in the working process, manufactures the finished tape film through the film making box 101 fixedly ...

Embodiment 2

[0036] refer to Figure 1-6 , a sealing tape gluing machine, comprising a base 1, a film-making box 101, a first roller set 103 and a second roller set 104 are fixedly connected to the base 1, and an adhesive glue is fixedly connected to the base 1 Box 2, a first extruding plate 201 and a second extruding plate 202 are slidingly connected in the viscose box 2, a third extruding plate 207 is fixedly connected in the viscose box 2, and a drawer is fixedly connected on the bottom wall of the base 1. The liquid tank 3, the liquid inlet end of the liquid suction tank 3 is fixedly connected with the liquid inlet pipe 301, the liquid outlet end of the liquid suction tank 3 is fixedly connected with the liquid outlet hose 302, and the end of the liquid outlet hose 302 away from the liquid suction tank 3 is fixedly connected to the The upper end surface of the third extruding plate 207, in the working process, manufactures the finished tape film through the film making box 101 fixedly ...

Embodiment 3

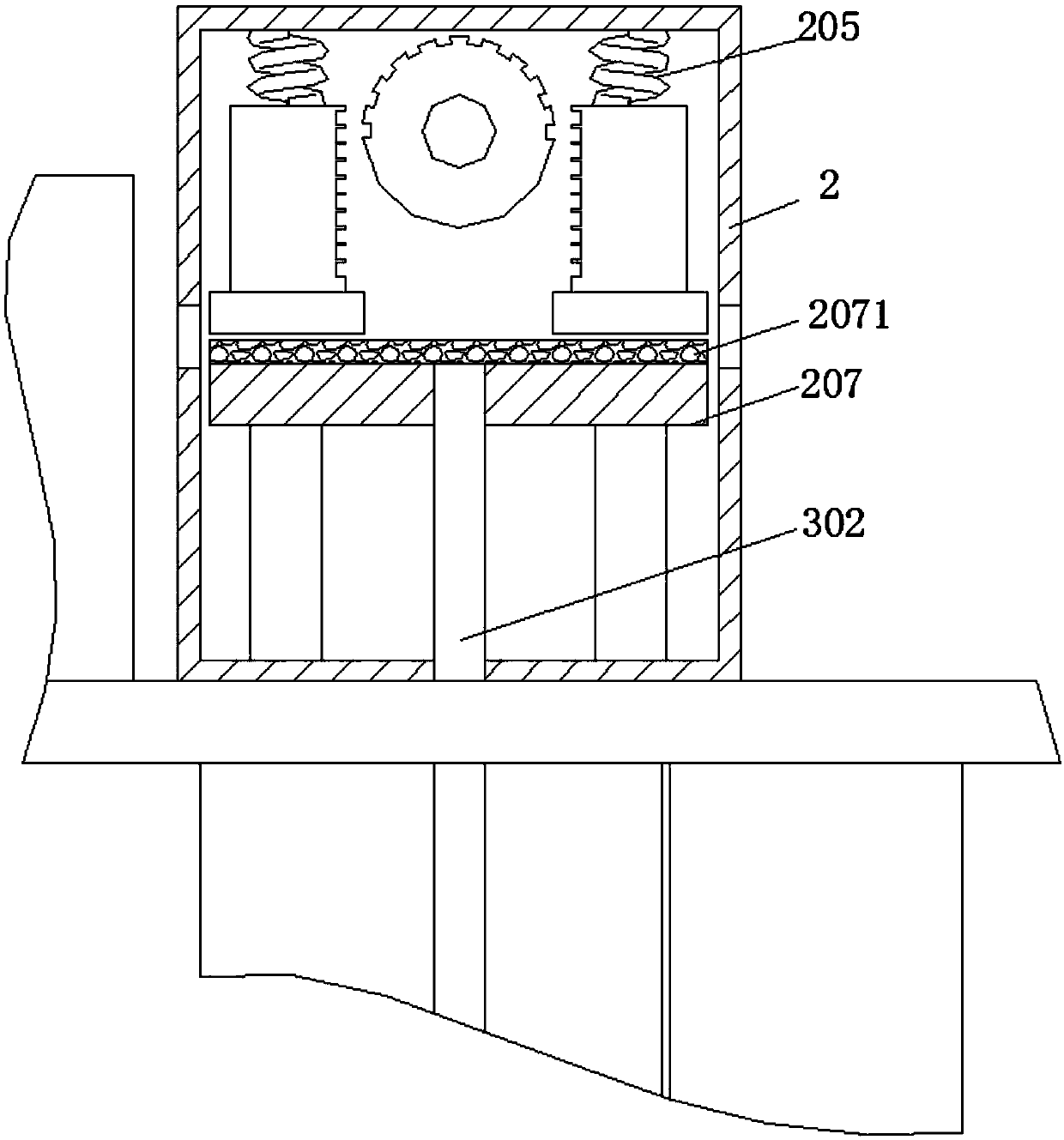

[0038] refer to Figure 3-5, a sealing tape gluing machine, basically the same as Embodiment 2, the difference is that the ends of the first gear plate 204 and the second gear plate 203 away from the extrusion plate are fixedly connected with a spring 205, and the spring 205 is far away from the gear One end of the plate is fixedly connected on the inner wall of the glue box 2 top.

[0039] The number of springs 205 is 2-4, and evenly distributed on the gear plate, in the working process, the springs 205 are fixedly connected to the ends of the first gear plate 204 and the second gear plate 203 away from the extrusion plate, so that The gear plate can be quickly reset, so as to prepare for the next extrusion of glue, and the number of springs 205 is 2-4, so that the reset speed of the gear plate can be improved.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap