Labeling device of anti-counterfeit label for bottled products

An anti-counterfeit label and labeling technology, which is applied in the field of label pasting, can solve the problems of slow response speed, aesthetic impact, and high cost, and achieve the effects of faster response speed, simple structure, and improved labeling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following is a further detailed description through specific implementations:

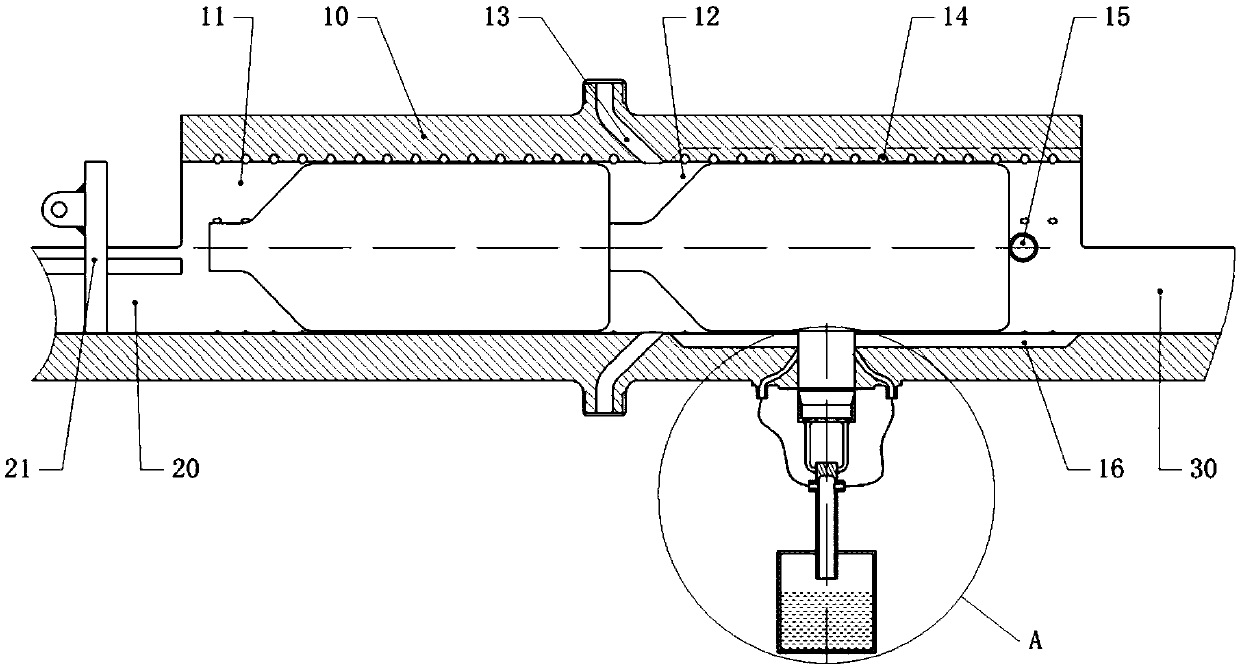

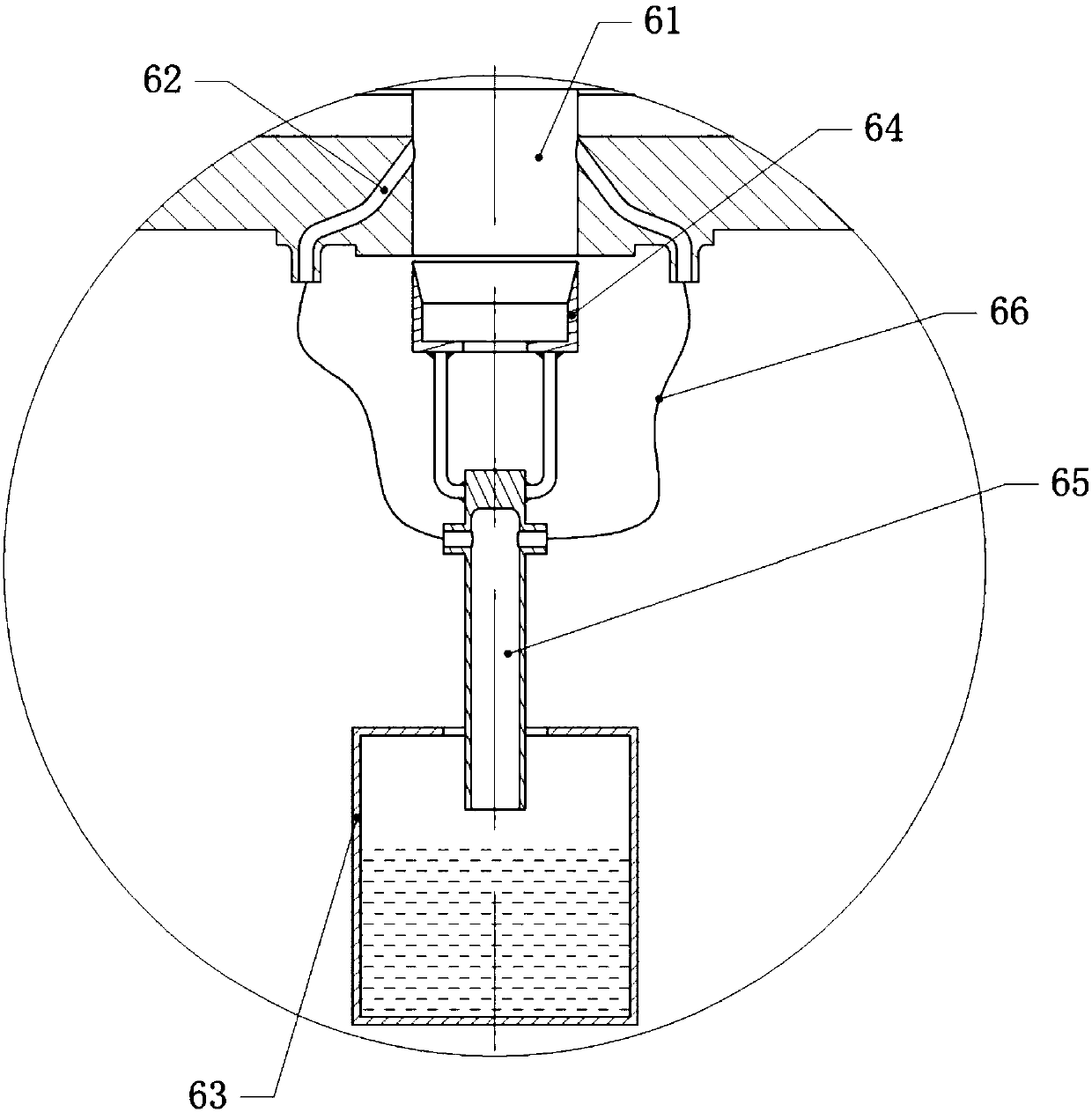

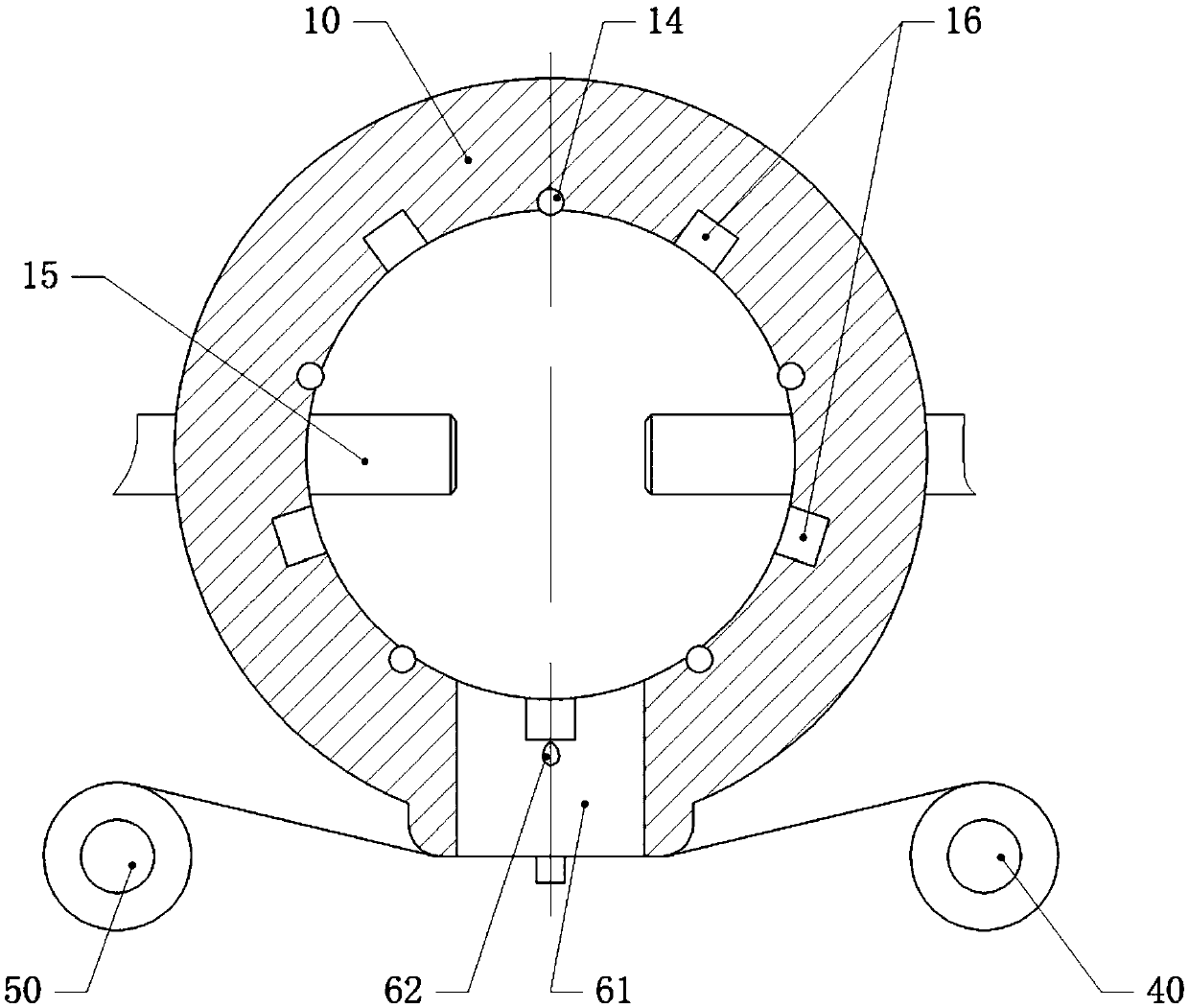

[0024] The reference signs in the drawings of the specification include: conveying pipe 10, inlet section 11, labeling section 12, air inlet 13, steel ball 14, limit pin 15, strip groove 16, feed groove 20, push block 21. The discharging trough 30, the feeding roller 40, the receiving roller 50, the label inlet 61, the spray hole 62, the glue storage tank 63, the cutter 64, the glue suction pipe 65, and the bellows 66.

[0025] As attached figure 1 As shown, the bottled product anti-counterfeiting label labeling device includes a frame and a conveying pipe 10. The conveying pipe 10 is fixed on the frame, and the conveying pipe 10 is in a circular tube shape; both ends of the conveying pipe 10 are respectively provided with the conveying pipe 10 integrally formed The feeding trough 20 and the discharging trough 30, the feeding trough 20 and the discharging trough 30 are both semi-circular trou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com