Sweet potato starch production method

A production method and technology of sweet potato starch, which is applied in the field of sweet potato starch processing, can solve the problems of wasting sweet potatoes and low starch yield, and achieve the effects of reducing water consumption, increasing yield, and improving filtration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

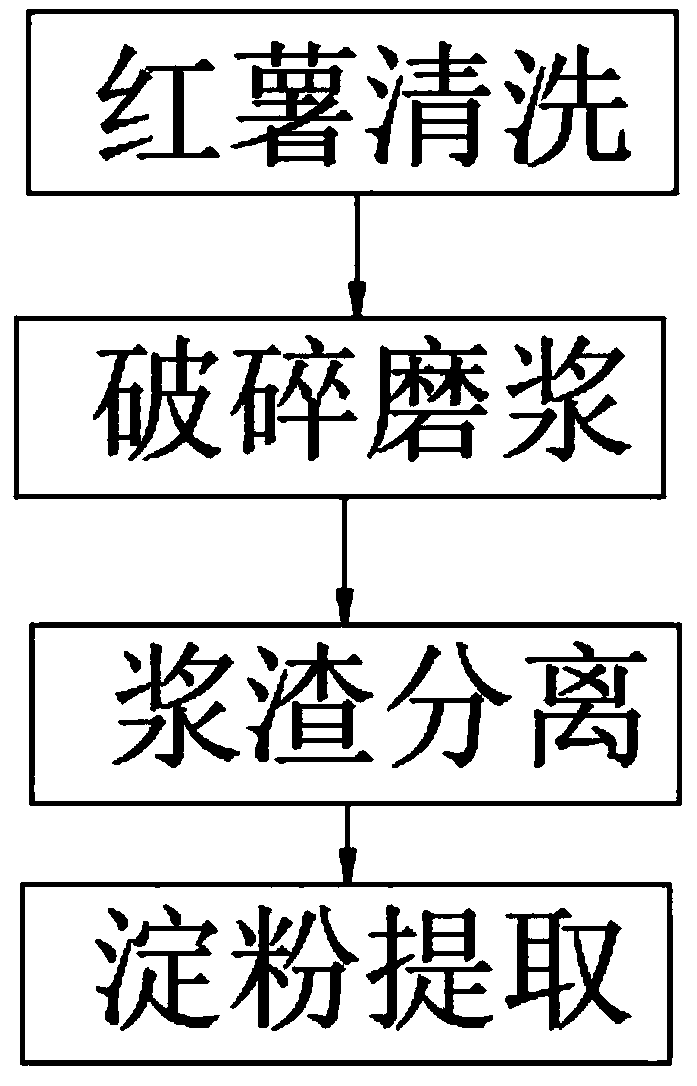

[0041] Such as figure 1 Shown, a kind of sweet potato starch production method, described concrete steps are as follows:

[0042] (1), sweet potato cleaning: put the sweet potato in the washing machine to clean for 2 hours;

[0043] (2), crushing and refining: crush the dried potato, and add clear water according to the mass ratio of material to liquid, after stirring evenly, add a certain amount of lime milk solution for soaking;

[0044] (3), pulp and residue separation: grind after soaking, and sieve to obtain starch milk;

[0045] (4) Starch extraction: Ten equal portions of starch milk are placed in a centrifuge for separation in batches, and the upper layer waste liquid is removed after centrifugation to obtain starch.

[0046] The washing machine in the step (1) is a paddle washing machine.

[0047] In the step (2), after the dried potato is crushed, it is added into clean water according to the mass ratio of solid to liquid, and the mass ratio of solid to liquid is ...

Embodiment 2

[0055] Such as figure 1 Shown, a kind of sweet potato starch production method, described concrete steps are as follows:

[0056] (1), sweet potato cleaning: put the sweet potato in the washing machine to clean for 2 hours;

[0057] (2), crushing and refining: crush the dried potato, and add clear water according to the mass ratio of material to liquid, after stirring evenly, add a certain amount of lime milk solution for soaking;

[0058] (3), pulp and residue separation: grind after soaking, and sieve to obtain starch milk;

[0059](4) Starch extraction: Ten equal portions of starch milk are placed in a centrifuge for separation in batches, and the upper layer waste liquid is removed after centrifugation to obtain starch.

[0060] The washing machine in the step (1) is a paddle washing machine.

[0061] In the step (2), after the dried potato is crushed, it is added into clean water according to the mass ratio of solid to liquid, and the mass ratio of solid to liquid is 5...

Embodiment 3

[0069] Such as figure 1 Shown, a kind of sweet potato starch production method, described concrete steps are as follows:

[0070] (1), sweet potato cleaning: put the sweet potato in the washing machine to clean for 2 hours;

[0071] (2), crushing and refining: crush the dried potato, and add clear water according to the mass ratio of material to liquid, after stirring evenly, add a certain amount of lime milk solution for soaking;

[0072] (3), pulp and residue separation: grind after soaking, and sieve to obtain starch milk;

[0073] (4) Starch extraction: Ten equal portions of starch milk are placed in a centrifuge for separation in batches, and the upper layer waste liquid is removed after centrifugation to obtain starch.

[0074] The washing machine in the step (1) is a paddle washing machine.

[0075] In the step (2), after the dried potato is crushed, it is added into clean water according to the mass ratio of solid to liquid, and the mass ratio of solid to liquid is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com