Garment printing method

A printing method and clothing technology, which is applied in the field of clothing, can solve the problems of darkening gloss, being unsuitable for electrostatic printing, reducing the color fixing rate of printing, etc., and achieves the effect of simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

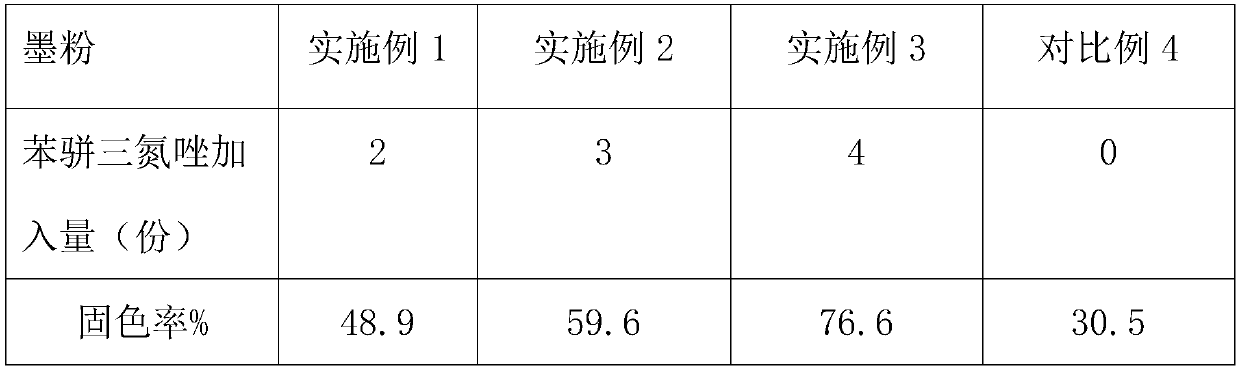

Embodiment 1

[0033] A kind of garment printing method, described specific steps are as follows:

[0034] (1) Charge the conductor plate to form a potential on the surface of the photoconductor;

[0035] (2) Project the pattern onto the surface of the photoconductor through the lens from top to bottom;

[0036] (3), then evenly absorb the toner on the surface of the photoconductor;

[0037] (4) Press the clothes with a pressing plate and smooth them on the surface of the photoconductor;

[0038] (5) The toner is melted, cooled and solidified on the clothes by heating with the heating roller.

[0039] In the step (1), the voltage for charging the conductor plate is 5500V, and a layer of selenium is plated on the surface of the photoconductor.

[0040] In the step (3), the toner is magnetically adsorbed from the ink cartridge to the magnetic roller beside the conductor plate, and then the toner is adsorbed on the surface of the photoconductor by the potential of the photoconductor surface....

Embodiment 2

[0051] A kind of garment printing method, described specific steps are as follows:

[0052] (1) Charge the conductor plate to form a potential on the surface of the photoconductor;

[0053] (2) Project the pattern onto the surface of the photoconductor through the lens from top to bottom;

[0054] (3), then evenly absorb the toner on the surface of the photoconductor;

[0055] (4) Press the clothes with a pressing plate and smooth them on the surface of the photoconductor;

[0056] (5) The toner is melted, cooled and solidified on the clothes by heating with the heating roller.

[0057] In the step (1), the voltage for charging the conductor plate is 5500V, and a layer of selenium is plated on the surface of the photoconductor.

[0058] In the step (3), the toner is magnetically adsorbed from the ink cartridge to the magnetic roller beside the conductor plate, and then the toner is adsorbed on the surface of the photoconductor by the potential of the photoconductor surface....

Embodiment 3

[0069] A kind of garment printing method, described specific steps are as follows:

[0070] (1) Charge the conductor plate to form a potential on the surface of the photoconductor;

[0071] (2) Project the pattern onto the surface of the photoconductor through the lens from top to bottom;

[0072] (3), then evenly absorb the toner on the surface of the photoconductor;

[0073] (4) Press the clothes with a pressing plate and smooth them on the surface of the photoconductor;

[0074](5) The toner is melted, cooled and solidified on the clothes by heating with the heating roller.

[0075] In the step (1), the voltage for charging the conductor plate is 5500V, and a layer of selenium is plated on the surface of the photoconductor.

[0076] In the step (3), the toner is magnetically adsorbed from the ink cartridge to the magnetic roller beside the conductor plate, and then the toner is adsorbed on the surface of the photoconductor by the potential of the photoconductor surface. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com