Long needle valve for fuel injection valve

A technology of fuel injection valve and long needle, which is applied in the field of long needle valve, can solve the problems of high processing cost, increase of moving parts, energy loss of high-pressure oil, etc., achieve accuracy and stability, reduce power loss, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

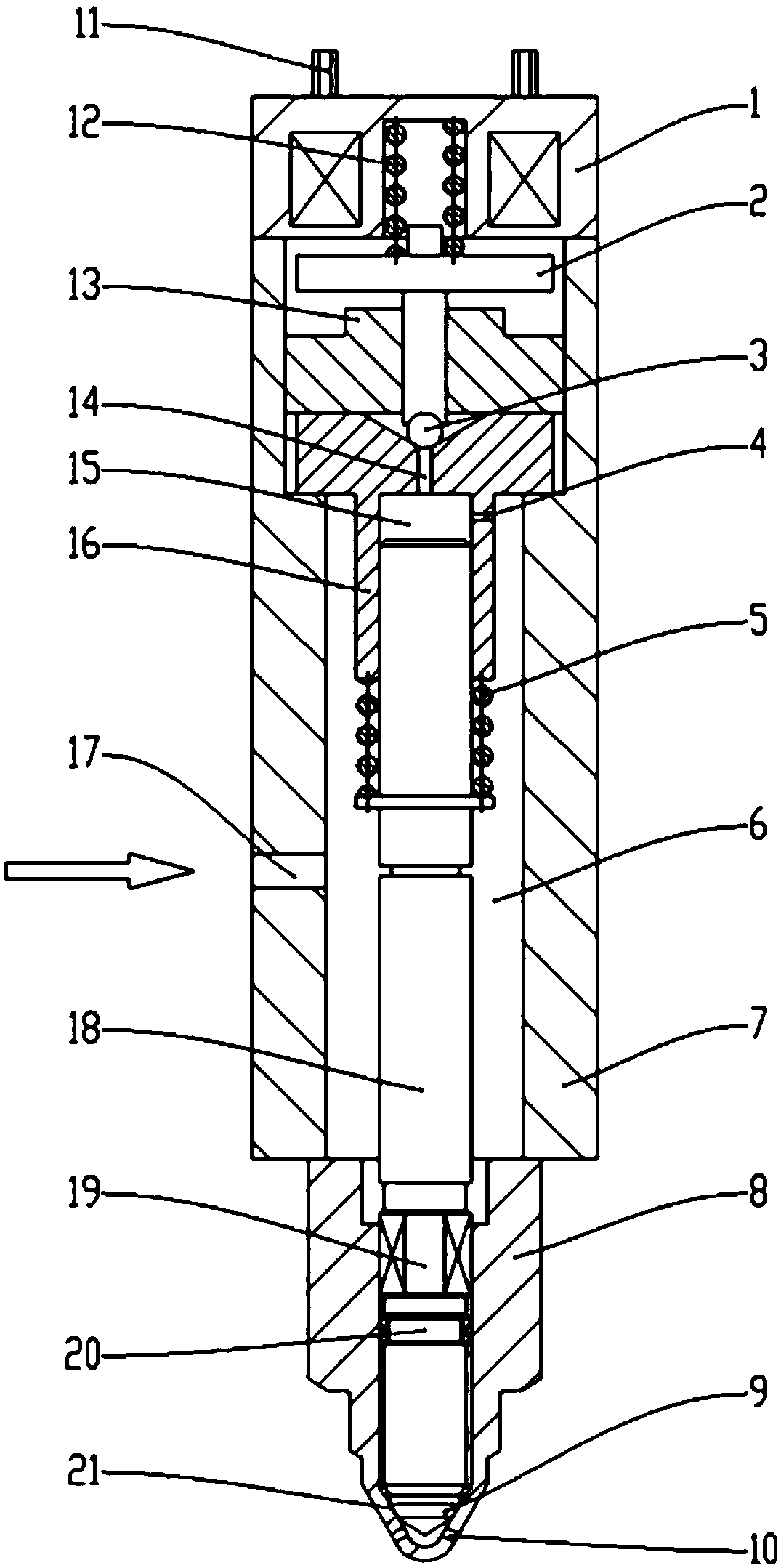

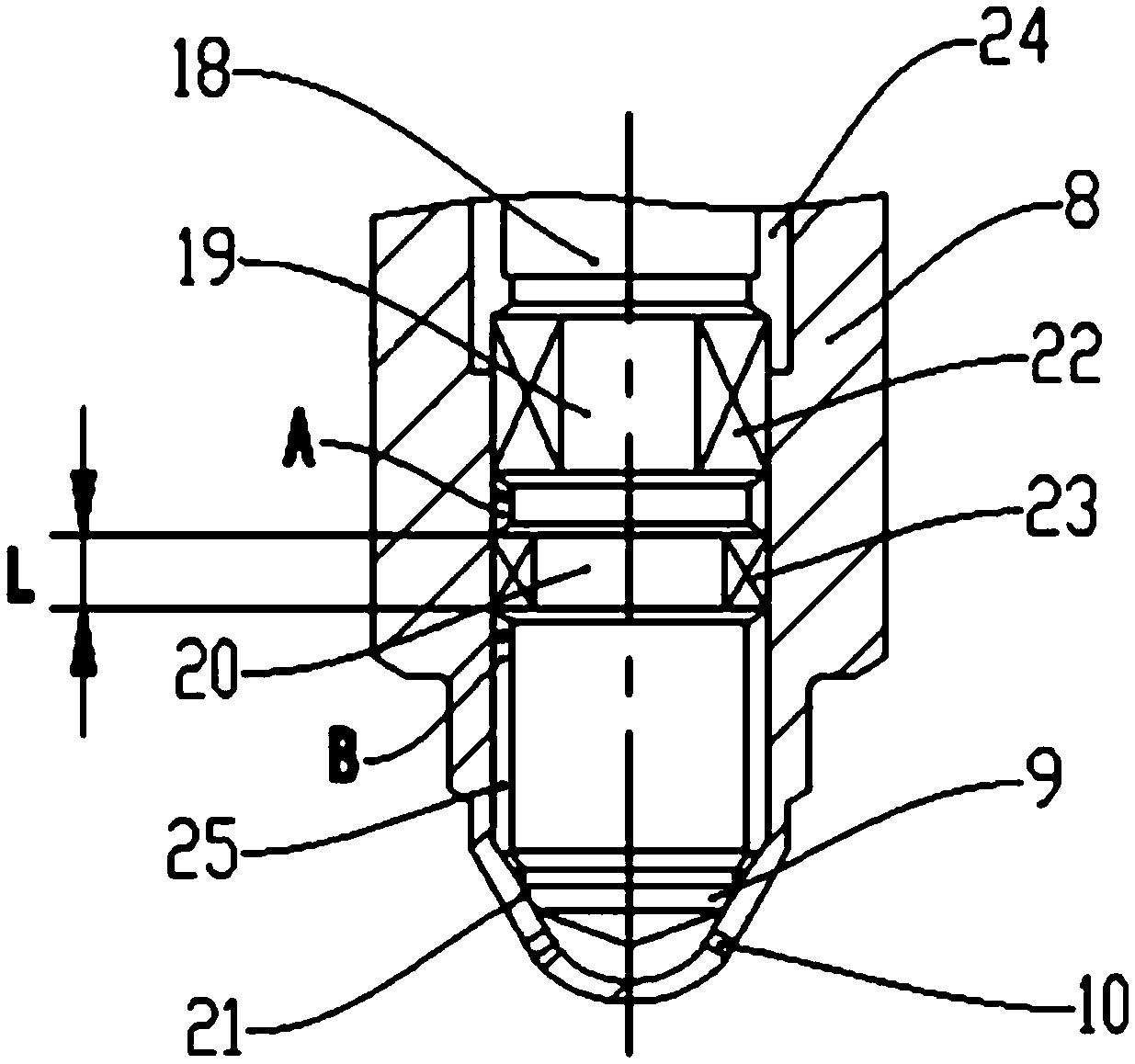

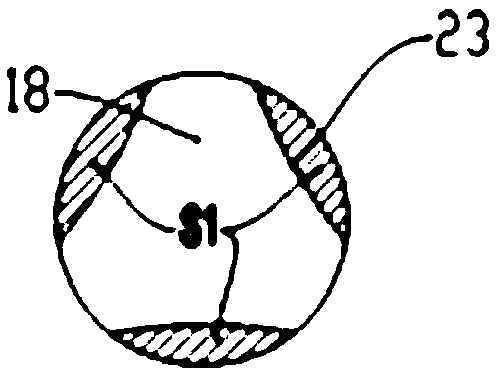

[0027] like Figure 1-6 Show, figure 1 A long-needle fuel injector profile is shown. The fuel injection valve mainly includes electromagnet 1, electromagnet spring 12, armature 2, sealing ball 3, valve sleeve 16, pressure regulating spring 5, fuel injector body 7, long needle valve 18, needle valve body 8, 9 needles The valve sealing cone, 10 nozzle hole, 11 terminal, 14 oil outlet hole and other components, the valve sleeve 16 is axially pressed in the concave cavity on the upper part of the injector body 7 by the control valve seat 13, and the lower part of the valve sleeve 16 extends Into the high-pressure chamber 6 inside the injector body 7, the end surface of the needle valve body 8 is pressed against the lower end surface of the injector body 7, and several injection holes 10 are arranged on the needle valve body 8, and the fuel can pass throu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com