Method for quickly and jointly measuring various element components in special high-aluminum high-manganese steel by utilizing spark source atomic emission spectrometry

A special high-aluminum high-manganese steel, atomic emission spectroscopy technology, applied in thermal excitation analysis, material excitation analysis, etc., can solve the problems of long analysis time, high cost, and inability to detect multiple elements, and achieve short time and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

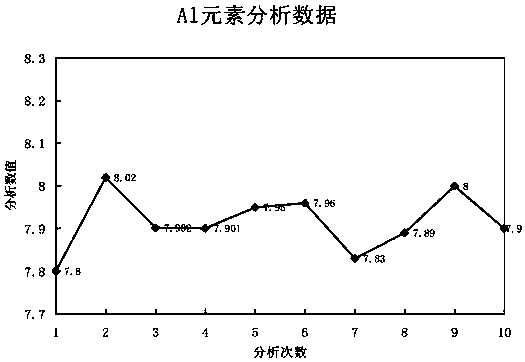

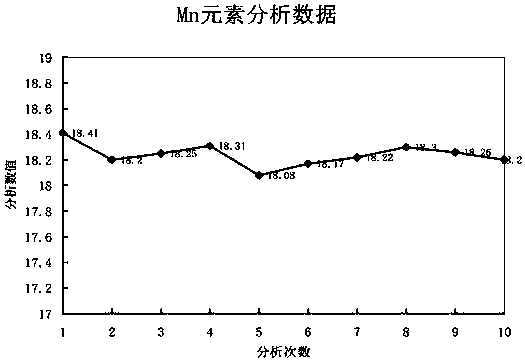

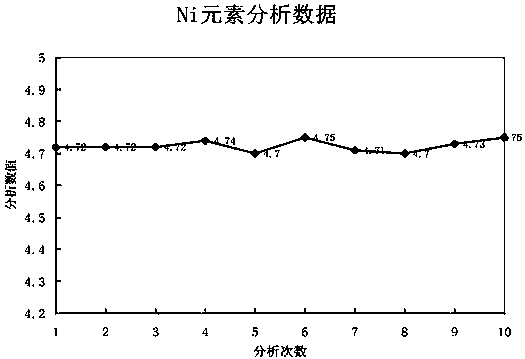

Image

Examples

Embodiment Construction

[0028] Below in conjunction with embodiment the present invention is described in further detail.

[0029] The present invention utilizes spark source atomic emission spectrometry to quickly and jointly determine a method for various elemental components of special high-aluminum high-manganese steel, and the method includes the following technical solutions:

[0030] The equipment used in the method: QSG750-II vacuum direct-reading spectrometer of German OBLF company

[0031] Standard samples used in the method: GBW01399 standard sample provided by General Institute of Iron and Steel Research, trace element standard sample provided by Angang Iron and Steel Research Institute, YSBS20111-99 standard sample provided by Shanghai Iron and Steel Research Institute, GSBA68073-92 standard sample provided by Shenyang Standard Sample Research Institute , the GSB H40068-93 standard sample provided by the Fushun Steel Works Research Institute of the General Iron and Steel Research Institu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com