Conical surface discharge test method for powder bin

A discharge test, powder technology, applied in the direction of measuring electricity, measuring electrical variables, testing dielectric strength, etc., can solve the problems of poor safety, explosion, etc., and achieve the effect of performance improvement and good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

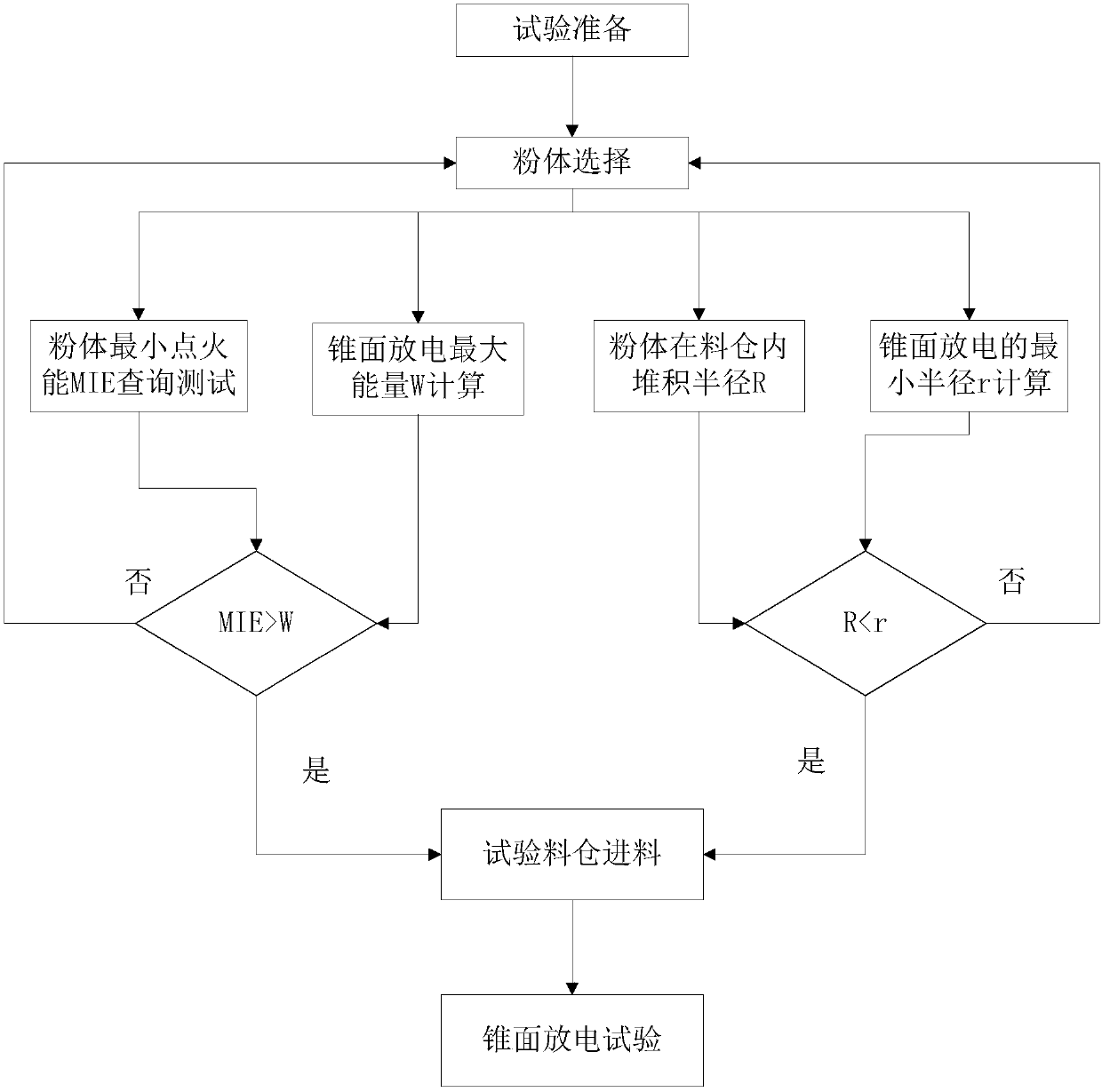

[0018] A powder silo cone surface discharge test method, such as figure 1 As shown, the determination of the minimum ignition energy MIE of the powder is determined. After inquiry, the minimum ignition energy of the polyethylene powder is 10mJ; the maximum energy W of the powder discharge in the cone surface of the silo is calculated: the diameter of the ground silo is 3m, and the accumulated powder The median diameter of the silo is 0.1mm, and the maximum energy of the cone surface discharge is calculated to be 2.42mJ; the minimum radius of the cone surface discharge of the powder in the silo is determined: according to the calculation method of the safe material level, the safe material level of a polyethylene silo is 1.75m, that is, the radius of 1.01m is the minimum radius of the conical surface discharge of the silo. According to the above data, for a grounded silo with a diameter of 3m, polyethylene powder with a median diameter of 0.1mm can be selected for testing; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com