Solid cold air generator structure for space propulsion system

A space propulsion and generator technology, which is applied to the propulsion system devices of space navigation vehicles, jet propulsion devices, machines/engines, etc., can solve problems such as flameout, and achieve the effects of increasing packing density, preventing falling off, and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

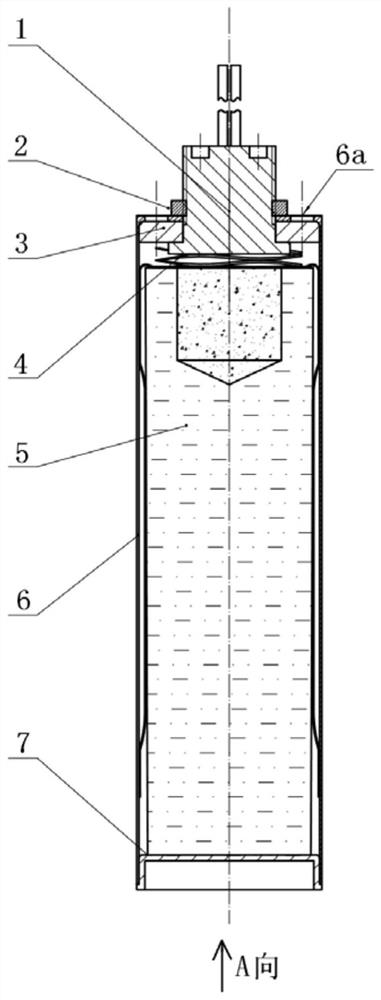

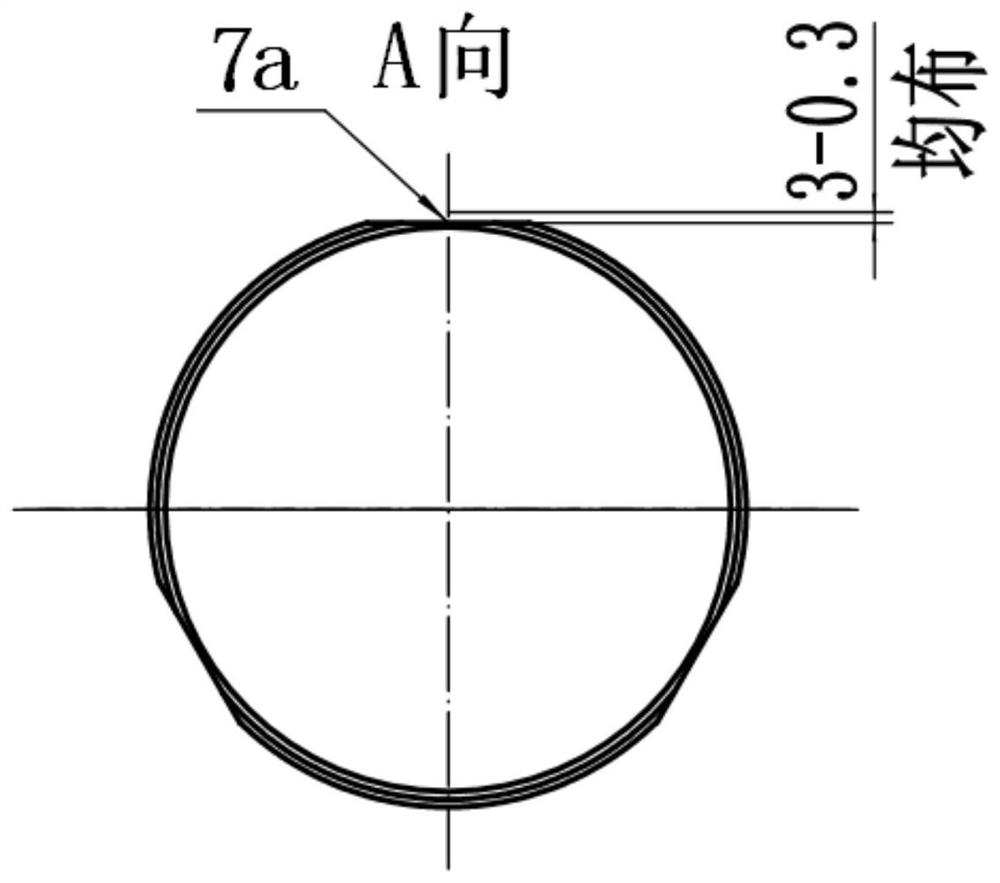

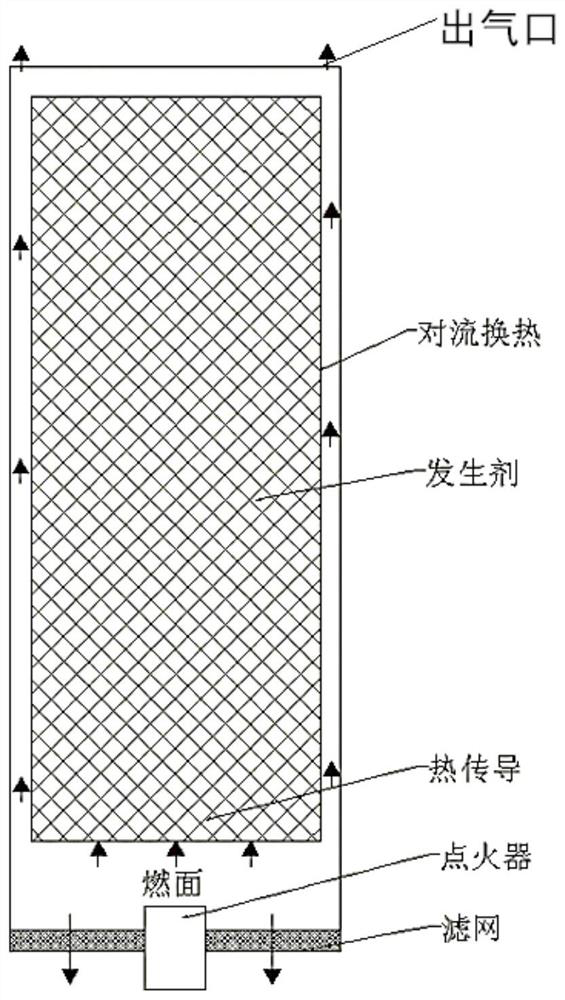

[0039] A solid cold air generator structure for a space propulsion system according to the present invention, such as figure 1 As shown, it includes: an igniter 1 , a backing ring 2 , a filter screen 3 , a support ring assembly 4 , a powder column component 5 , a housing 6 , and a U-shaped bottom cover 7 .

[0040] One end of the igniter 1 protrudes from the inside of the casing 6 to the top, and is threadedly connected with the backing ring 2, which is located outside the casing 6; the backing ring 2 is used to fix the axial position of the igniter 1 .

[0041] The outer wall of the igniter 1 is covered with a filter screen 3, and the filter screen 3 is located inside the housing 6;

[0042] The grain part 5, the support ring assembly 4 and the housing 6 are sequentially assembled from the inside to the outside, and the grain part 5 is placed under the igniter 1 through the support ring assembly 4;

[0043] The U-shaped bottom cover 7 is placed under the grain part 5, and p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Radial size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com