High-efficiency ground torch and stable combustion measure thereof

A ground torch and burner technology, which is applied in the direction of combustion methods, use of multiple fuels, burners, etc., can solve the problems that the pressure of the torch gas cannot be increased, the combustion is incomplete, and the stability and safety of the torch system are affected. Ensure safe and stable operation, reduce air circulation resistance, and facilitate full combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, the present invention will be further described:

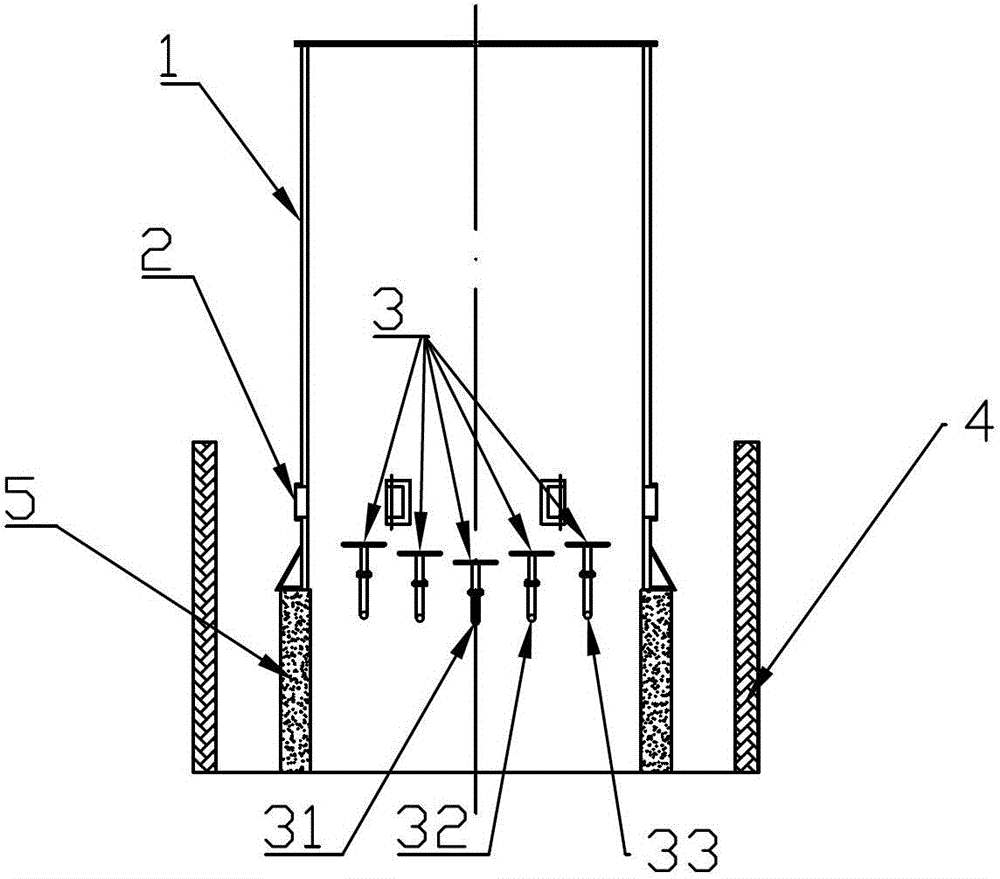

[0030] A ground torch, comprising a cylinder body 1, a fire viewing hole 2, a burner 3, a cylindrical foundation 5 and a control part, the cylinder body 1 is installed on the cylinder foundation 5, and the side wall of the cylinder body 1 is annularly distributed with A plurality of fire viewing holes 2 and burners 3 are divided into multiple stages and arranged inside the barrel 1 .

[0031] The burner 3 includes a first-stage burner 31, a second-stage burner 32 and a third-stage burner 33. The arrangement of the burners 3 adopts a "V"-shaped symmetrical arrangement, with the first-stage burner 31 in the middle, and the outwards in sequence The secondary burner 32 and the tertiary burner 33 are symmetrically arranged; the secondary burner 32 is located above the primary burner 31, the tertiary burner 33 is located above the secondary burner 32, and the adjacent two-stage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com