Double-sided coated glass applied to visible light and near-infrared light bands and production process of double-sided coated glass

A double-sided coating and near-infrared light technology, applied in optics, optical components, instruments, etc., can solve the problems of inconvenient magnetron sputtering coating line production, etc., to reduce light energy reflection, superior performance, and increase conversion rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

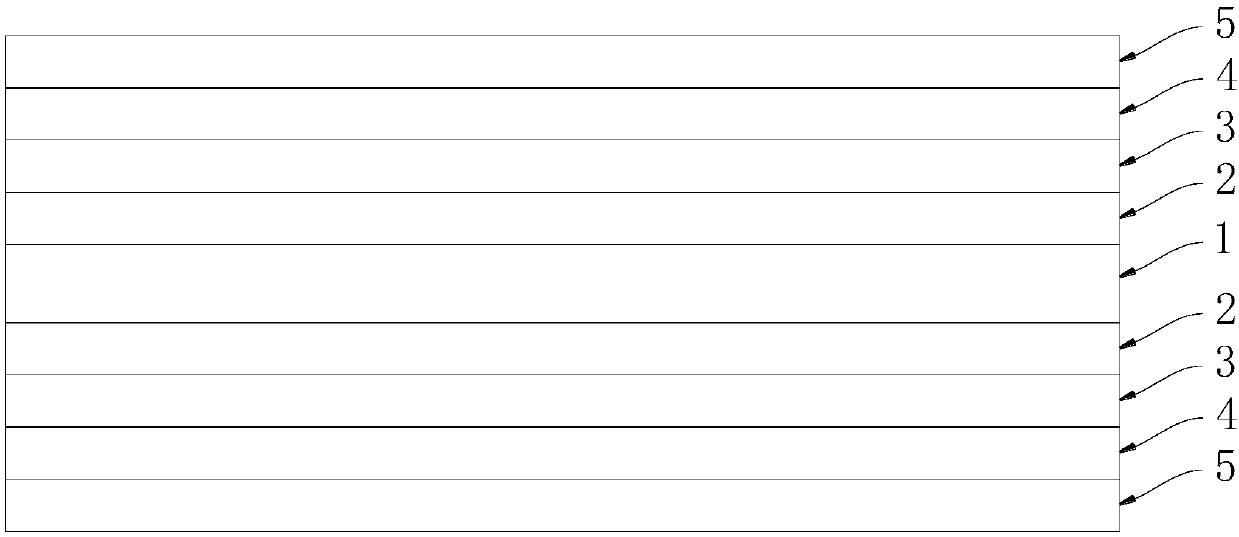

[0030] In this embodiment, the process of coating the AR antireflection and antireflection nanocomposite layer includes: preparing continuous magnetron sputtering coating equipment, and determining the first niobium oxide according to the design film system of the AR antireflection and antireflection nanocomposite layer Layer 2, the thickness of the first silicon dioxide layer 3, the second niobium oxide layer 4 and the second silicon dioxide layer 5 and the order of arrangement, the vacuum degree of the coating equipment is pumped to a background vacuum of 5.0E-3pa, and then each The coating box is filled with 120 sccm of Ar2 gas, and then filled with O2 gas. The oxygen content of the SiAl target is 60-75 SCCM, and the oxygen content of the Nb metal target is 80-90 SCCM. Then turn on the power supply corresponding to the target position. After the power supply is stable, The glass substrate 1 is sent into the coating box, and the glass substrate 1 passes through each sputterin...

Embodiment 2

[0032] In this embodiment, the process of plating the AR anti-reflection and anti-reflection nano-composite layer includes: preparing a single box sputtering coating device, installing Nb targets and Sial targets according to the design film system of the AR anti-reflection and anti-reflection nano-composite layer, The glass substrate is clamped on the film rack, the vacuum of the coating box is evacuated to 5.0E-3pa background vacuum, then the box is filled with 100 sccm of Ar2 gas, and then filled with O2 gas, the flow rate is controlled at 70-90 SCCM, and then the Nb target is turned on Turn on the power to the required setting value, set the number of revolutions of the glass substrate according to the preset film thickness, plate the first niobium oxide layer 2, close the NB target after completion, open the Sial target, press the preset film thickness The layer thickness sets the number of turns of the glass substrate, and the first silicon dioxide layer 3 is plated. Afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com