Etching method of silver nanowire, transparent conductive electrode and preparation method thereof

A technology of transparent conductive electrodes and silver nanowires, applied in the direction of conductive layers on insulating carriers, cable/conductor manufacturing, circuits, etc., can solve problems such as thinning and silver nanowire density reduction, and achieve small visual differences and consistent appearance , the appearance of the basic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with specific embodiments.

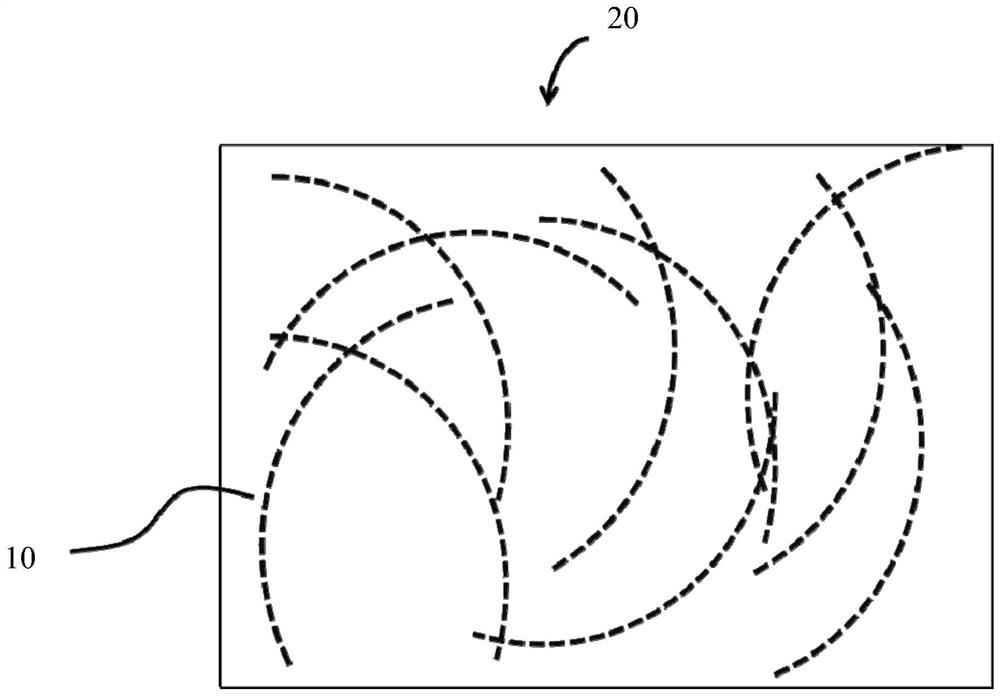

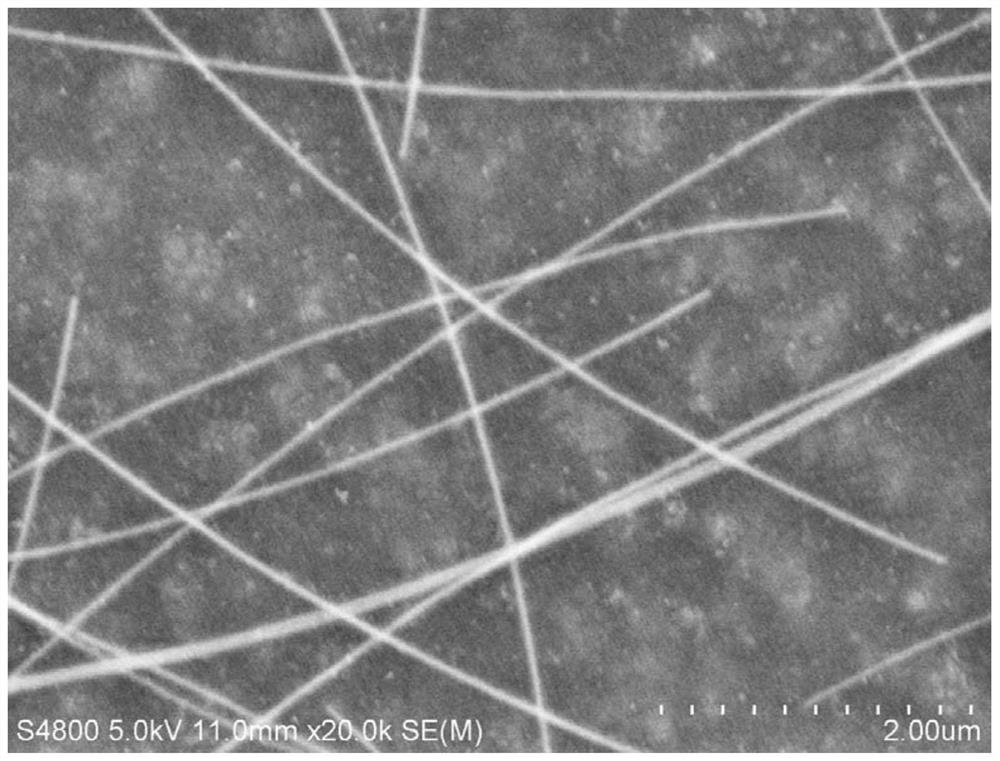

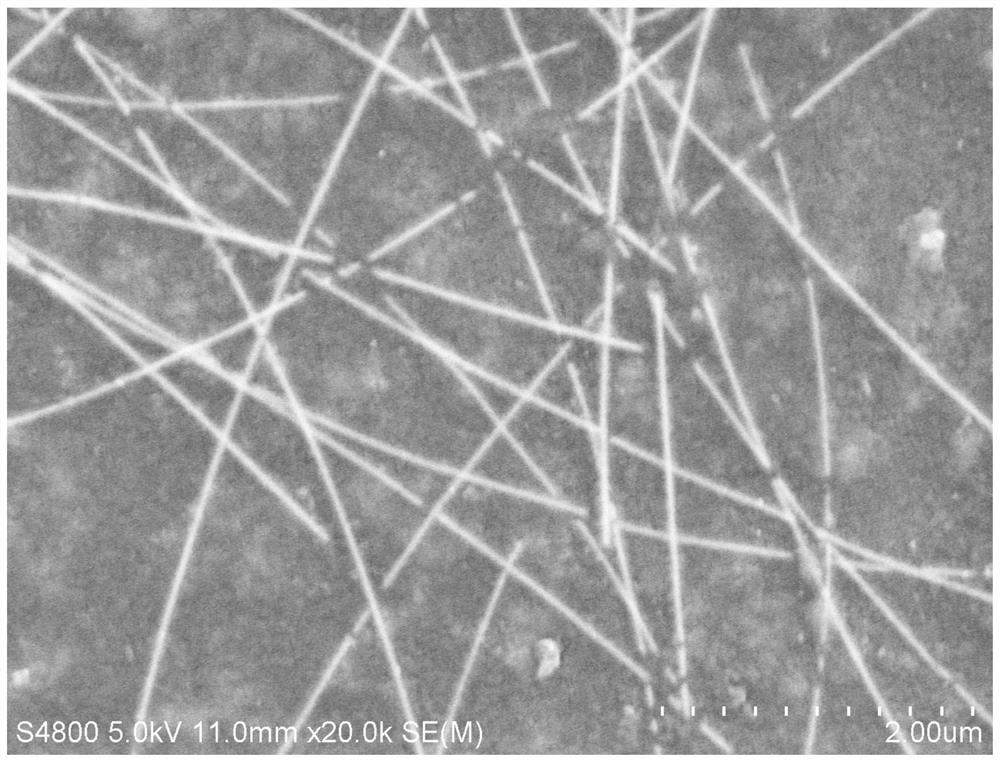

[0033] Usually, as Figure 1 ~ Figure 3 As shown, silver nanowires 10 are coated on a substrate to form a silver nanowire conductive film 20, and then the silver nanowire conductive film 20 is etched.

[0034] The etching method of silver nanowire 10 of the present invention cuts silver nanowire 10 into several line segments, such as figure 1 or image 3 As shown, the silver nanowire 10 after cutting cannot form an effective conductive network, and the electrical difference before and after etching is relatively large; and the silver nanowire 10 after cutting remains basically the same, so the optical properties of the silver nanowire conductive film 20 before and after etching The difference is small, and it can be used to prepare transparent electrodes with excellent quali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com