Boosting three-bridge-arm inverter and boosting adjustment method

A technology of three bridge arms and inverters, which is applied in the direction of converting AC power input to DC power output, output power conversion devices, electrical components, etc., which can solve the problem of serious heat generation of the down tube, reduce loss and reduce voltage ripple, the effect of improving system efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

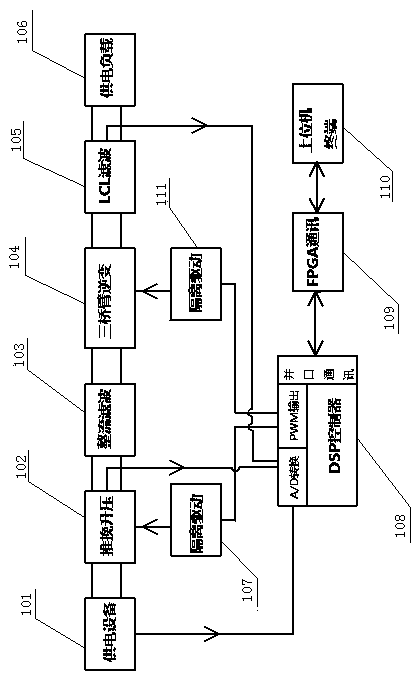

[0028] A step-up three-leg inverter, which consists of: a power supply equipment module, the power supply equipment module is connected to a push-pull boost module, the push-pull boost module is connected to a rectification and filtering module, and the The rectifier filter module is connected to the three-arm inverter bridge module, the three-arm inverter bridge module is connected to the LCL filter module, and the LCL filter module is connected to the power supply load;

[0029] The power supply equipment module, the push-pull boost module, and the LCL filter module output signals to the A / D conversion end of the DSP main controller respectively, and the PWM output port of the DSP main controller is connected to the isolation drive module respectively. A. The isolated drive module B is connected, the isolated drive module A is connected to the push-pull boost module, the isolated drive module B is connected to the three-arm inverter bridge module, and the DSP The main contro...

Embodiment 2

[0041] According to the step-up three-leg inverter described in Embodiment 1, the isolated drive module includes a signal conversion module, and the signal conversion module is respectively connected to the drive module, the voltage rectification and filtering module, and the DSP main controller. The voltage rectification and filtering module described above feeds back the rectified voltage to the IC control module through the coupling of electrically isolated signals, and the IC control module is connected to the power conversion circuit module, and the power conversion circuit module is connected to the voltage Rectifier filter module connection.

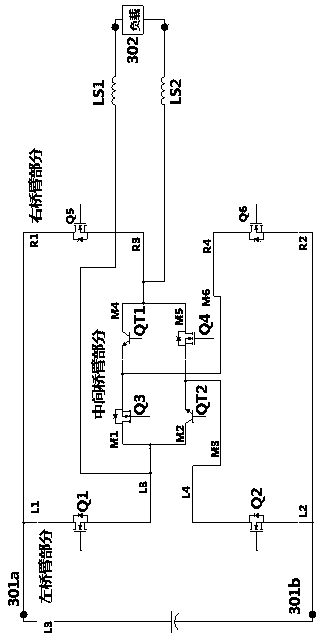

[0042] Figure 8 A block diagram for the isolated drive, including:

[0043] Main control IC module 301: controls the output of PWM through IC, and performs chip enable, overvoltage, undervoltage, overcurrent and other controls.

[0044] The power conversion module 302: controls the power part through the output of PWM, and exci...

Embodiment 3

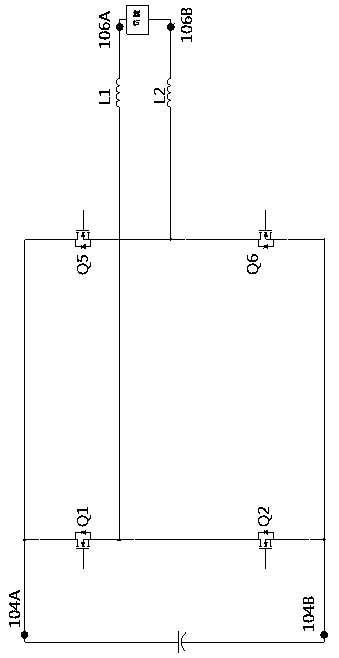

[0050] According to the step-up three-leg inverter described in Embodiment 1 or 2, the three-leg inverter bridge module includes a left bridge arm, an intermediate bridge arm and a right bridge arm, and the left bridge arm includes a MOS tube Q1, MOS tube Q2, the middle bridge arm includes IGBT tube QT1, IGBT tube QT2, MOS tube Q3, MOS tube Q4, the right bridge arm includes MOS tube Q5, MOS tube Q6; the pin L1 of the left bridge arm and the positive input of the capacitor Terminal connection, the L2 pin of the left bridge arm is connected to the negative input terminal of the capacitor, the L3 pin of the left bridge arm is connected to the M1 and M2 of the middle bridge arm, the L4 pin of the left bridge arm is connected to the M3 of the middle bridge arm, The pin R1 of the right bridge arm is connected to the positive input terminal of the capacitor, the R2 pin of the right bridge arm is connected to the negative input terminal of the capacitor, the R3 pin of the right bridge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com