Optical fiber macro bending online monitoring system and method

A monitoring system and macro-bending technology, which is applied in the field of optical fiber macro-bending online monitoring system, can solve the problems of high total power, small proportion of optical power, and inability to accurately judge the link, so as to reduce the misjudgment rate and improve accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

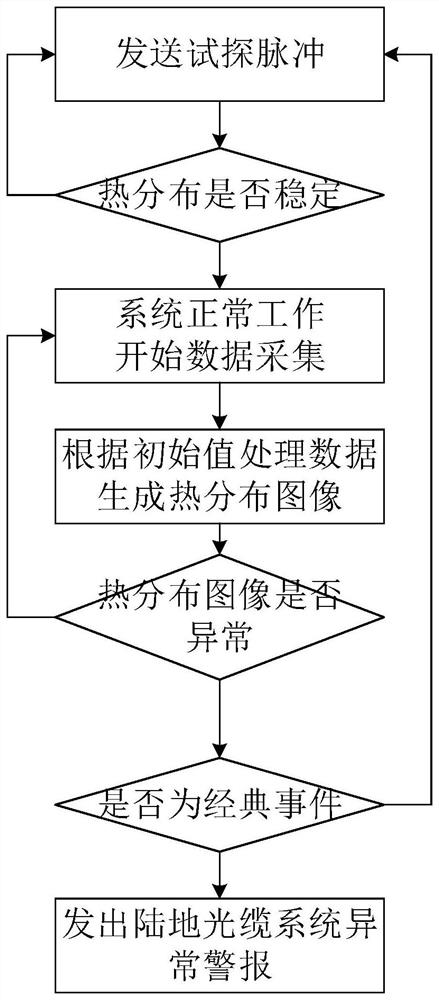

[0045] The terrestrial optical cable links are usually buried on the shallow surface and are easily affected by changes in external temperature (direct sunlight, heat transfer, etc.). adiabatic environment. The fiber optic cable can be filled with thermal insulation material to ensure that the optical fiber in the cable link is in a constant temperature and humidity environment even in complex situations.

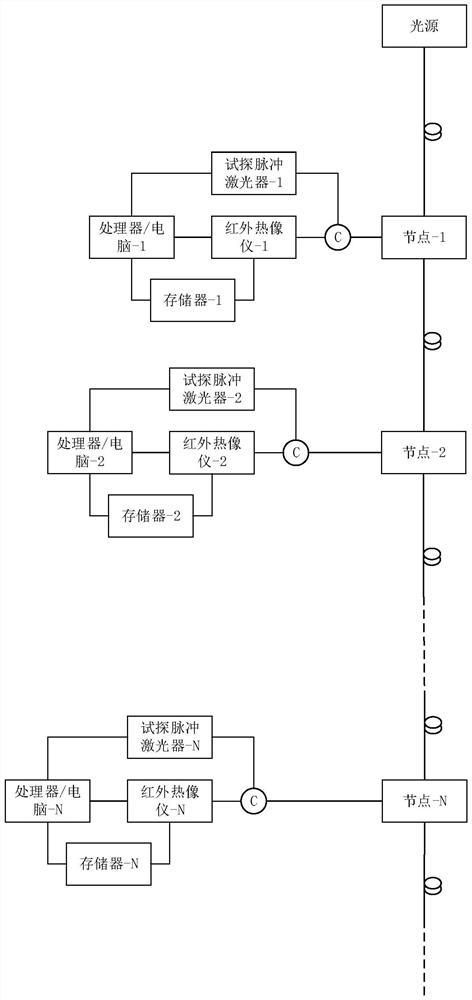

[0046] Place infrared thermal imaging cameras, memory, processors, test pulse lasers and other equipment at the relay station of the terrestrial optical cable link. In the system initialization stage, firstly, a test pulse laser is used to send a test pulse, and the infrared thermal imaging camera continuously collects and observes the thermal distribution data of the fiber end face. When the thermal distribution becomes stable, the data is stored. The initial value of the system between the previous nodes, which is used as the reference basis for system correction when cl...

Embodiment 2

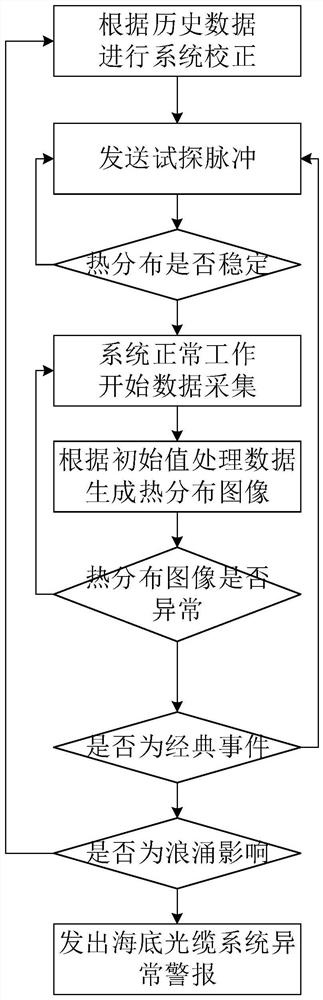

[0050] The submarine optical cable link is laid on the seabed, and the ambient temperature usually remains constant, so there is no need to fill the cable with insulating material, but the nodes of the submarine optical cable are usually included in the optical cable, so it is judged by monitoring the thermal distribution of the optical fiber end face whether there is In the case of macrobending eavesdropping, it is first necessary to miniaturize the thermal imaging camera so that devices such as thermal imaging cameras can be integrated in the submarine optical cable link system.

[0051] The observation process is basically the same as that of the terrestrial optical cable system. The difference is that some classic events similar to disturbances will occur in the submarine optical cable system. After a period of time, the disturbance can disappear and the system will recover itself. For example, submarine surges and wave fluctuations will bring vibrations to submarine optica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com