Unique identifier-based positioning system for staff and devices in transformer station

A positioning system and substation technology, which is applied in the field of personnel and equipment positioning systems in substations, can solve the problems of short safety distance, dense distribution, and many occlusions of electrical equipment, achieve high reliability and positioning accuracy, short positioning time period, and practical strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

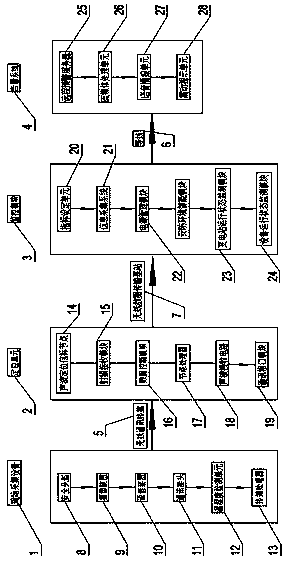

[0026] Such as Figure 1-2 As shown, the substation personnel and equipment positioning system based on the unique identification code according to the embodiment of the present invention includes a field collection device 1, a positioning unit 2, a monitoring module 3 and an alarm system 4, and the field collection device 1 passes through a wireless communication terminal. 5 is connected to the positioning unit 2, the positioning unit 2 is connected to the monitoring module 3 through a wireless data transmission base station 7, and the monitoring module 3 is connected to the alarm system 4 through a wire 6;

[0027] Wherein, the on-site acquisition device 1 includes a safety helmet 8, a camera device 9, a voice device 10, a communication connector 11, a temperature and humidity detection unit 12, and a terminal processor 13 connected in sequence, and the positioning unit 2 includes a sound wave positioning device connected in sequence. Beacon node 14, radio frequency receivin...

Embodiment 2

[0030] Such as figure 1As shown, the safety helmet 8 is worn on the head of the operator, and after the time synchronization signal sent by the wireless data transmission base station 7, it can cooperate with the SLB node 14 to control the SLB node 14 Carry out time synchronization. After the time synchronization is completed, an ultrasonic positioning signal is sent. The acoustic positioning beacon node 14 is fixed in the set space and has specific position coordinates, and can receive the time synchronization signal transmitted by the safety helmet 8 and the The ultrasonic positioning signal sent by the safety helmet 8 can decode the ultrasonic signal sent by the safety helmet 8 to obtain positioning information by cooperating with the safety helmet 8 to perform time synchronization after receiving the time synchronization signal, and The positioning information is transmitted to the monitoring module 3 and the alarm system 4. When the monitoring module 3 and the alarm syste...

Embodiment 3

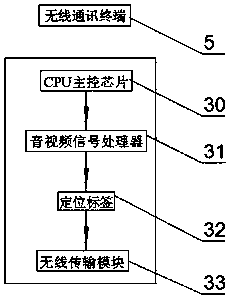

[0032] Such as Figure 1-2 As shown, the wireless data transmission base station 7 includes a CPU main control chip 30, an audio and video signal processor 31, a positioning tag 32 and a wireless transmission module 33, and the position information of the operator used to collect is encoded and passed through the wireless transmission module 33 Transmit to monitoring module 3, described monitoring module 3 is connected with described remote early warning server 26, and monitoring module 3 transmits the position coordinates of the operator who wears safety helmet 8 to described remote early warning server 26, with described remote early warning In the server 26, the movement track of the operator is formed. The ultrasonic positioning signal sent by the safety helmet 8 is an ultrasonic signal using ultrasonic spread spectrum coding technology. The frequency band of the ultrasonic positioning signal is 20K ~ 25KHz. The streaming media processing unit 27 The text of the remote war...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com