Sintering agent for dry particulate refractory composition

A technology of sintering agent and composition, which is applied in the field of dry granular refractory composition, sintering agent for dry granular refractory composition, and consolidation products, and can solve the problems of harmful, inappropriate, and inability to ensure the particle mixture of refractory materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

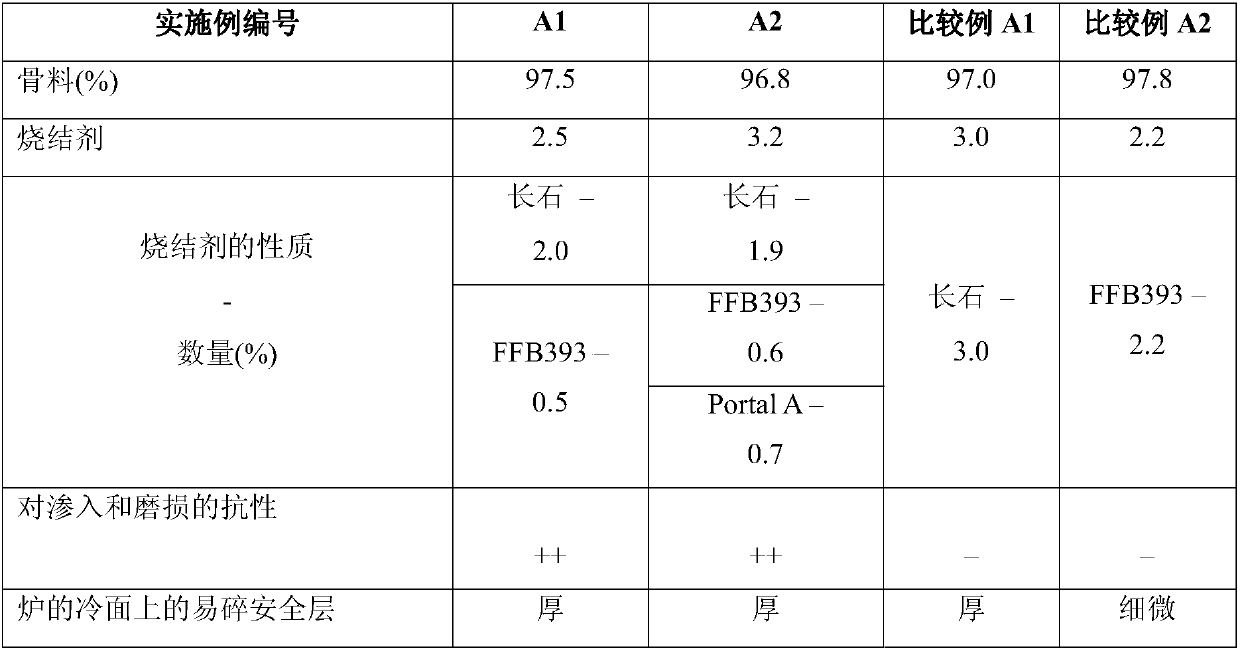

[0117] Composition of dry refractory mixture

[0118] Dry granular refractory compositions according to the present invention and outside the present invention were prepared as follows.

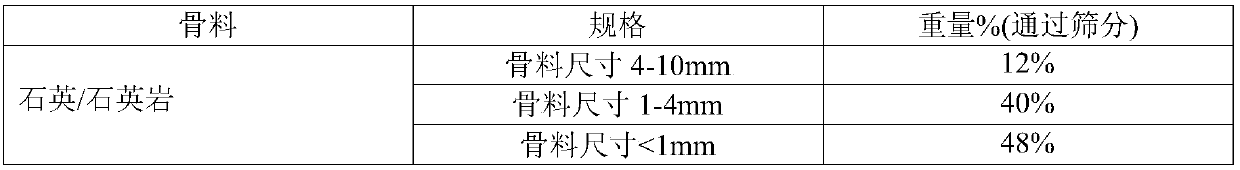

[0119] The following materials were used in all examples:

[0120]

[0121] Table 1

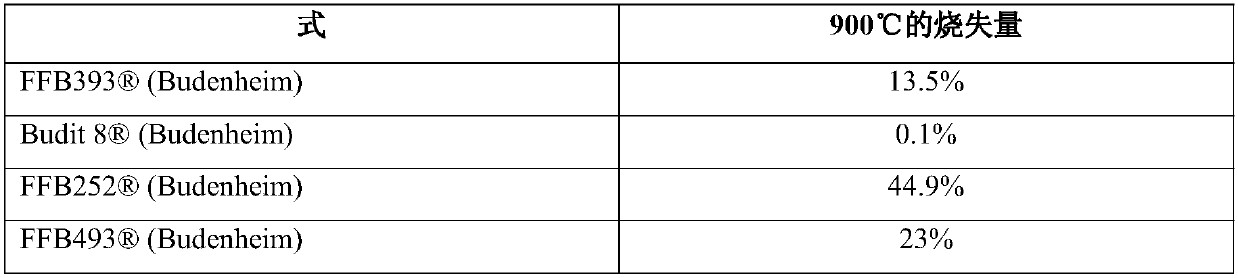

[0122] Use the following compounds:

[0123] - Anorthite (Sibelco);

[0124] - (Budenheim): Potassium dihydrogen orthophosphate (mainly potassium phosphate);

[0125] - (Budenheim): polyphosphoric acid, sodium citrate (mainly sodium phosphate);

[0126] - (Budenheim): phosphoric acid, trisodium citrate, dodecahydrate;

[0127] - (Budenheim): sodium dihydrogen orthophosphate;

[0128] - (Care Chemicals): sodium silicate (Na 2 SiO 3 );

[0129] -FERRO Frit TF 9015SE and Frit TF 90 5158M, the composition and loss on ignition are shown in Table 2.

[0130]

Sintered 1

Sinter 2

Loss on ignition at 900°C

0.37%

0.34%

SiO 2

50.4%

48.7%

CaO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com