Ethylene-vinyl acetate copolymer, method for preparing same, and solar cell packaging sheet using same

A vinyl acetate, solar cell technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of lowering forming temperature, increasing defect rate, lowering sheet productivity, etc., to improve cross-linking speed and excellent weather resistance. and thermal stability, the effect of high crosslinking rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] In the production method of the EVA copolymer resin according to the present invention, a polymerization initiator including two or more peroxide polymerization initiators is preferably added at a concentration of 1000 to 3000 ppm. If the concentration of the polymerization initiator is less than 1000 ppm, the reaction temperature during polymerization is low, undesirably resulting in low conversion to EVA copolymer resin and making molecular weight control difficult. If the concentration of the polymerization initiator is greater than 3000ppm, the reaction temperature during the polymerization is very high, which may decompose the resin, and the decomposition of vinyl acetate will generate acetic acid, which may damage the reaction radicals, which undesirably damages the safety issue.

[0037] In the preparation method of the EVA copolymer resin according to the present invention, specific examples of alkyl peroxyneodecanoate compounds (A) suitable for use as initiators...

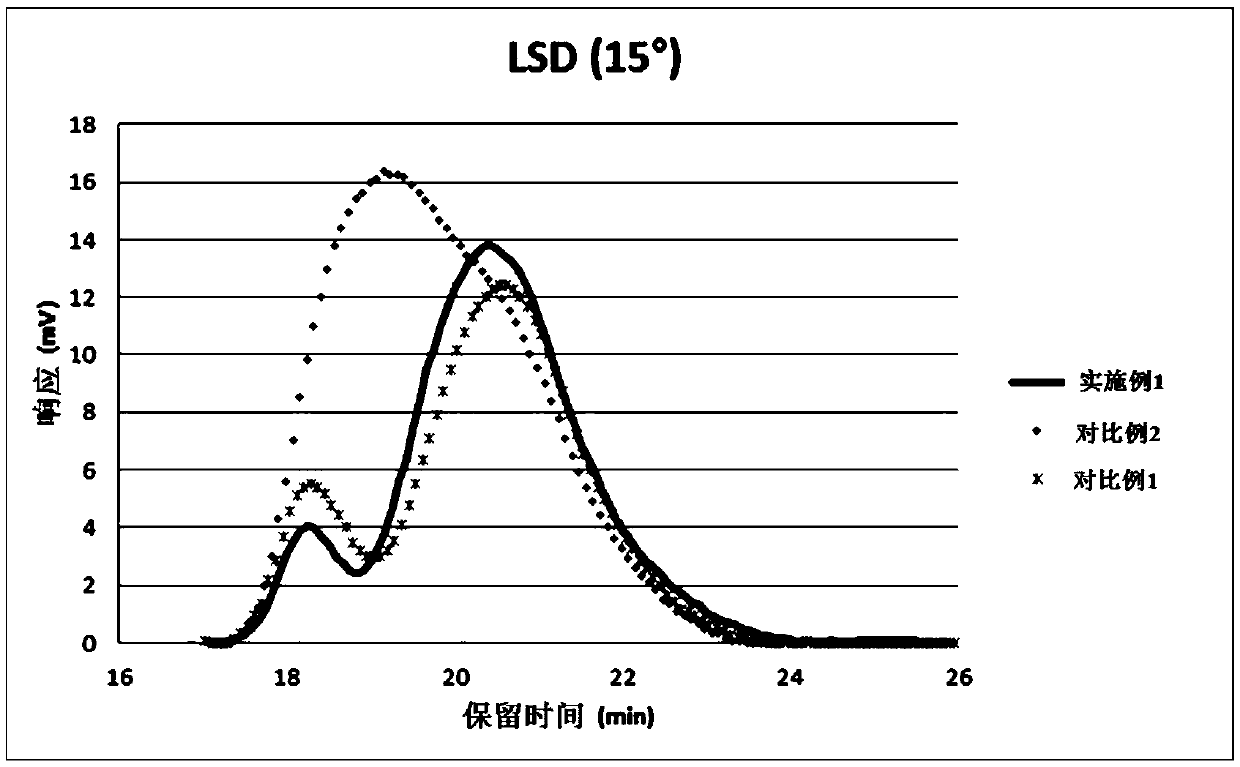

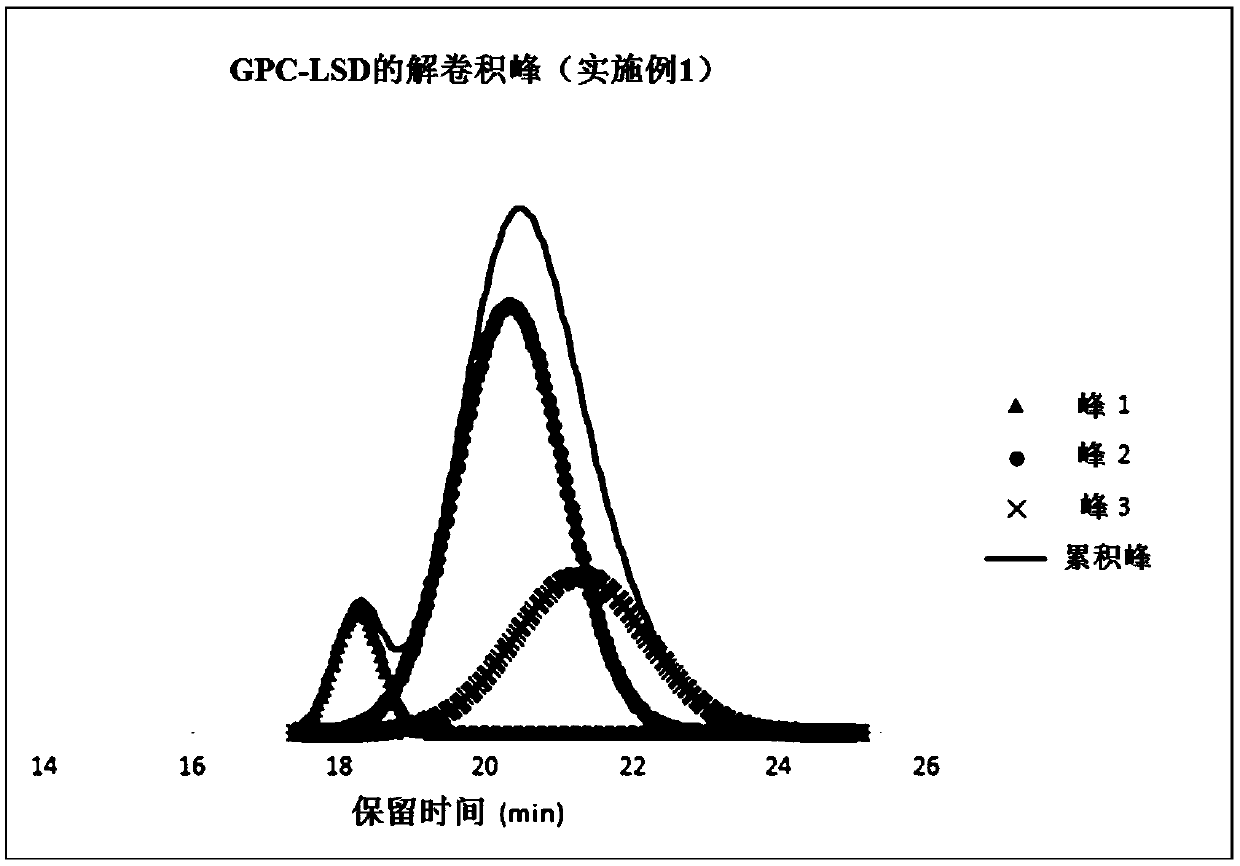

Embodiment 1

[0076] In the first reaction stage, 72% by weight of ethylene monomer and 28% by weight of vinyl acetate monomer are injected into the reactor, and tert-butyl peroxyneodecanoate (TBND), tert-butyl peroxypivalate (TBPV) and tert-butyl peroxy-2-ethylhexanoate (TBPO) were mixed in a weight ratio of 45:30:25, and the resulting mixture was injected into the reactor as a radical initiator. In the second reaction stage, tert-butyl peroxyneodecanoate (TBND), tert-butyl peroxypivalate (TBPV) and tert-butyl peroxy-2-ethylhexanoate (TBPO) were mixed in a ratio of 10:20 : 70 weight ratio mixing, weigh 2000ppm of the resulting mixture relative to ethylene monomer and vinyl acetate monomer, and then use a high temperature pump to continuously inject it into the reactor. including 2650kg / cm 2 The EVA copolymer resin was prepared under the conditions of the polymerization pressure, the polymerization temperature of 230° C. and the polymerization time of 4 minutes. As determined by GPC-LSD d...

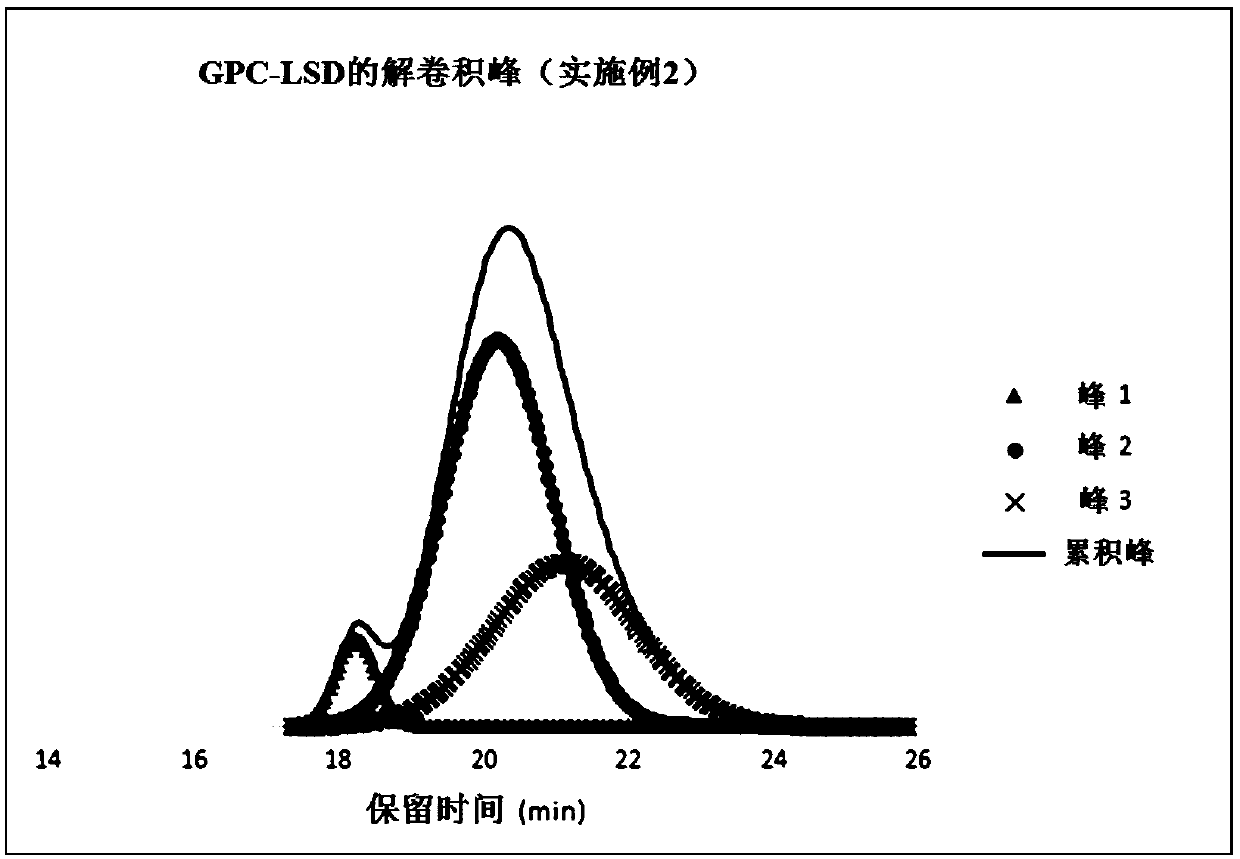

Embodiment 2

[0078] In the first reaction stage, 72% by weight of ethylene monomer and 28% by weight of vinyl acetate monomer are injected into the reactor, and tert-butyl peroxyneodecanoate (TBND), tert-butyl peroxypivalate (TBPV), tert-butyl peroxy-2-ethylhexanoate (TBPO) and tert-butyl peroxy-3,5,5-trimethylhexanoate (TBPIN) in a weight ratio of 40:30:25:5 ratio and inject the resulting mixture into the reactor as a free radical initiator. In the second reaction stage, tert-butyl peroxyneodecanoate (TBND), tert-butyl peroxypivalate (TBPV), tert-butyl peroxy-2-ethylhexanoate (TBPO) and peroxy- tert-butyl 3,5,5-trimethylhexanoate (TBPIN) was mixed in a weight ratio of 10:20:60:10, and the resulting mixture was weighed at 2000 ppm relative to ethylene monomer and vinyl acetate monomer, and then used The high temperature pump continuously injects it into the reactor. including 2650kg / cm 2 The EVA copolymer resin was prepared under the conditions of the polymerization pressure, the polyme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com