A Method of Improving the Utilization Rate of Laser Deposition Powder

A technology of laser deposition and utilization rate, which is applied in the direction of improving energy efficiency, process efficiency, coating, etc., can solve the problems of poor effective utilization rate of powder and low deposition efficiency, so as to improve utilization rate, increase deposition efficiency, improve The effect of effective utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

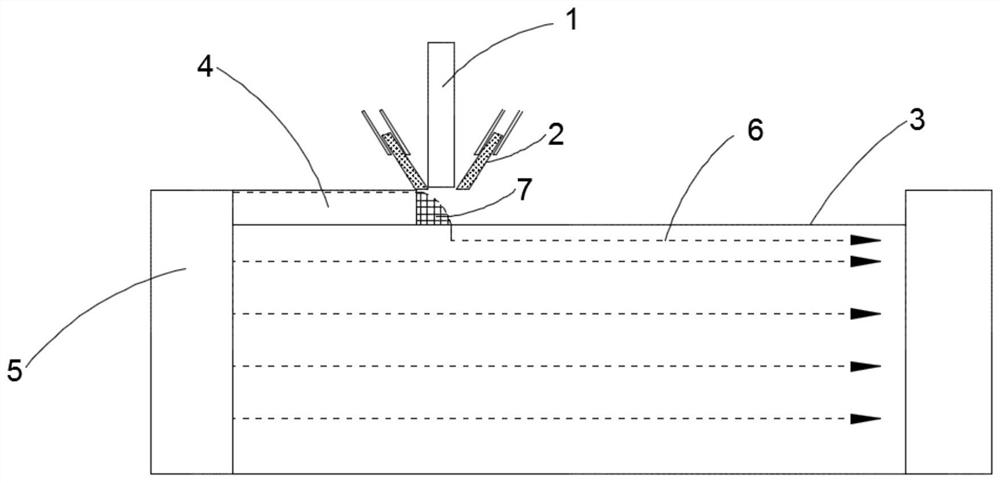

Image

Examples

Embodiment 1

[0028] A method for improving the utilization rate of laser deposition powder, comprising the steps of:

[0029] (1) The mixed metal powders of Fe, Ni, and Co powders with mass percentages of 70%, 18%, and 12% are used, and the particle size of the metal powders is 325 mesh; 30Cr13 stainless steel plates are used as the base material, wherein the stainless steel plates The chemical composition is C: 0.30%, Cr: 13.0%, Ni: 0.50%, Si: 0.80%, Mn: 0.70%, P: 0.03%, S: 0.02%, and the rest is Fe. The steel plate is used in the annealed state, The size is 40mm×40mm;

[0030] (2) Weigh 200g of Fe, Ni and Co powders according to the proportion, mix them in a powder mixer for 8 hours, put them in a vacuum drying oven, dry them at 90°C for half an hour, and put them into a scraper type powder feeder; Polish the surface of the stainless steel substrate, wipe it clean with alcohol and dry it naturally;

[0031] (3) Set the laser cladding process parameters, the laser power is 1800W, the sc...

Embodiment 2

[0034] A method for improving the utilization rate of laser deposition powder, comprising the steps of:

[0035] (1) The mixed metal powders of Fe, Ni, and Co powders with mass percentages of 70%, 18%, and 12% are used, and the particle size of the metal powders is 325 mesh; 30Cr13 stainless steel plates are used as the base material, wherein the stainless steel plates The chemical composition is C: 0.26%, Cr: 12.0%, Ni: 0.30%, Si: 0.5%, Mn: 0.50%, P: 0.02%, S: 0.01%, and the rest is Fe. The steel plate is in the annealed state, The size is 40mm×40mm;

[0036] (2) Weigh 200g of Fe, Ni and Co powders according to the proportion, mix them in a powder mixer for 8 hours, put them in a vacuum drying oven, dry them at 90°C for half an hour, and put them into a scraper type powder feeder; Polish the surface of the stainless steel substrate, wipe it clean with alcohol and dry it naturally;

[0037] (3) Set the laser cladding process parameters, the laser power is 1800W, the scanning...

Embodiment 3

[0040] A method for improving the utilization rate of laser deposition powder, comprising the steps of:

[0041] (1) The mixed metal powders of Fe, Ni, and Co powders with mass percentages of 70%, 18%, and 12% are used, and the particle size of the metal powders is 325 mesh; 30Cr13 stainless steel plates are used as the base material, wherein the stainless steel plates The chemical composition is C: 0.35%, Cr: 14.0%, Ni: 0.60%, Si: 1.00%, Mn: 1.00%, P: 0.04%, S: 0.03%, and the rest is Fe. The use state of the steel plate is the annealed state, The size is 40mm×40mm;

[0042] (2) Weigh 200g of Fe, Ni and Co powders according to the proportion, mix them in a powder mixer for 8 hours, put them in a vacuum drying oven, dry them at 90°C for half an hour, and put them into a scraper type powder feeder; Polish the surface of the stainless steel substrate, wipe it clean with alcohol and dry it naturally;

[0043] (3) Set the laser cladding process parameters, the laser power is 3000...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com