Production process of hydraulic power backup tongs for oil pipe

A technology of hydraulic power and manufacturing technology, which is applied in the direction of drill pipe, casing, drilling equipment, etc., can solve the problems of high manufacturing cost, increased manufacturing difficulty, poor working stability, etc., and achieve good clamping stability and long service life , design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Take the fixing of the piston rod in the hydraulic cylinder as an example for further explanation

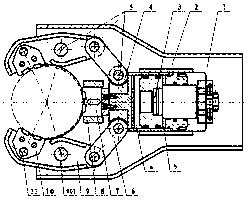

[0010] like figure 1 As shown, the piston rod 3 in the hydraulic cylinder is fixedly connected to the main body of the back tong 1, and the axis line of the piston rod 3 intersects and is perpendicular to the axis line of the clamped pipe string; The ends are vertically fixedly connected, and the two ends are respectively passed through two rotating shafts 5 and one end of two connecting rods 6 symmetrical to the axis line of the piston rod 3 to form a fixed hinge form of two rotary pairs; the two connecting rods 6 The other end passes through two rotating shafts 5 and one end of two clamping arms 9 symmetrical to the axis line of the piston rod 3 respectively to form a living hinge form of two rotary pairs; the middle part of the clamping arm 9 is provided with a connecting hole 901, The connecting hole 901 is fitted with the rotating shaft 5 in a gap, and the rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com