Domestic waste incinerator based on wind power transmission

A technology of domestic waste incineration and wind power, applied in incinerators, combustion methods, combustion types, etc., can solve the problems of difficult combustion of domestic waste and air pollution, and achieve the effects of improving feeding efficiency, sufficient combustion and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

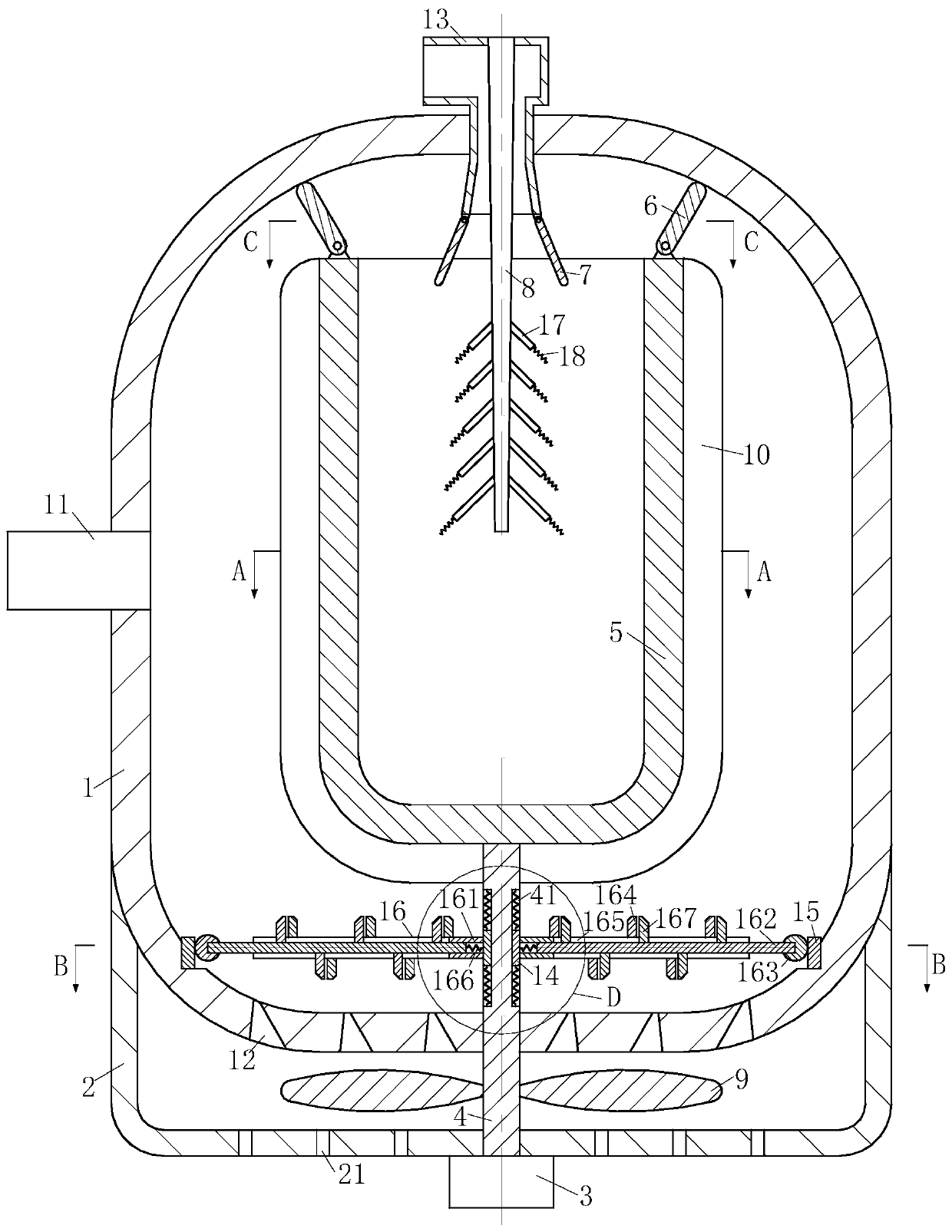

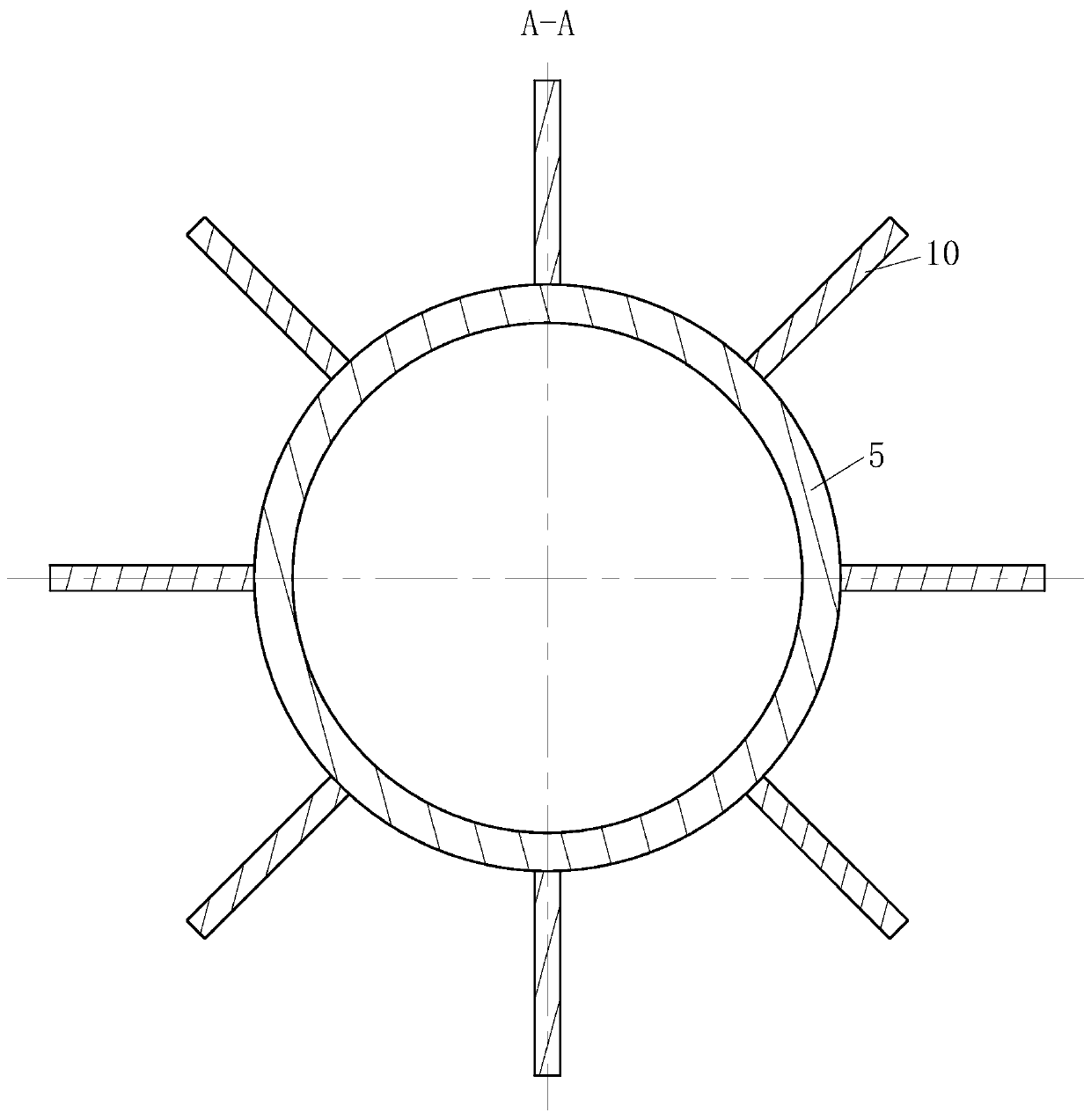

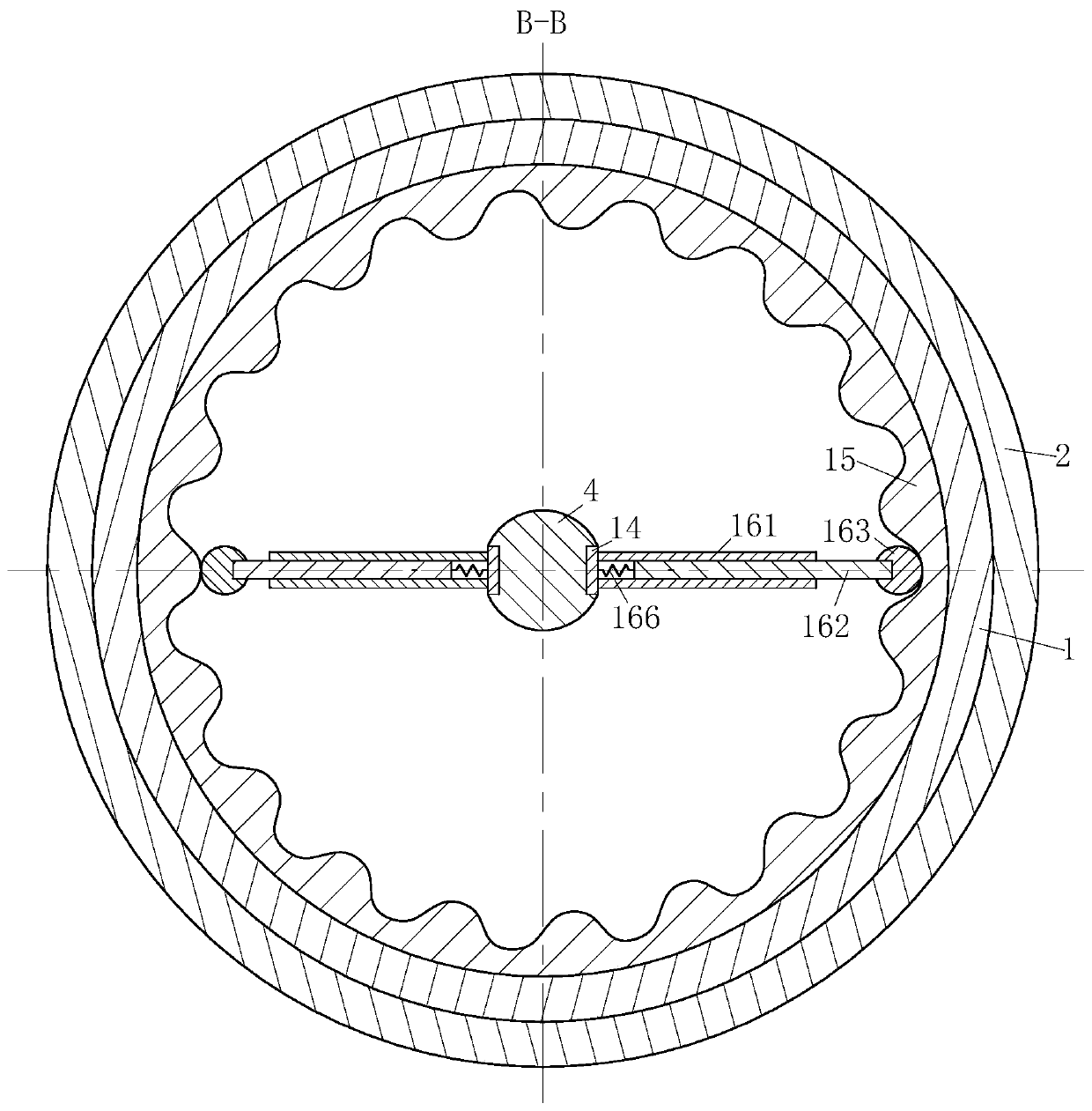

[0020] use Figure 1-Figure 5 A domestic waste incinerator based on wind power transmission of the present invention is described as follows.

[0021] Such as Figure 1-Figure 5 , a domestic waste incinerator based on wind power transmission according to the present invention, including a furnace body 1, a base 2, a motor 3, a transmission shaft 4, a combustion chamber 5, a feed door 6, a material blocking plate 7 and an oil supply rod 8 The base 2 is fixedly connected to the bottom of the furnace body 1, and the base 2 is provided with a plurality of air intake holes 21; the motor 3 is fixedly connected to the middle part of the lower end of the base 2; the lower end of the transmission shaft 4 is fixedly connected to the rotating shaft of the motor 3 On the transmission shaft 4 close to the base 2 are fixedly connected with a plurality of blast blades 9, the upper end of the transmission shaft 4 is fixedly connected with the bottom of the combustion chamber 5; the combustio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com