Patents

Literature

39results about How to "Easy to air dry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing belite-gypsum material by using sludge and waste gypsum through dry-process rotary kiln

The invention discloses a method for producing a belite-gypsum material by using sludge and waste gypsum through a dry-process rotary kiln. The method comprises the following steps of (1) melting a sludge ridge grain seed crystal with high water content into modified sludge residues; (2) proportioning raw materials of the modified sludge residues, the waste gypsum and a correcting material according to a certain ratio, and grinding the raw materials by using a vertical mill to form raw material powder; (3) delivering the raw material powder obtained in the step (2) into a dry-process rotary kiln system, and calcining the raw material powder to form clinker; and (4) grinding the obtained clinker to obtain powder with the fineness of 0.08mm and the screen residue content of less than 20%. The method disclosed by the invention is simple, low in investment and cost, free of other secondary pollution and capable of absorbing the sludge and the waste gypsum on a large scale and in a recycling way, greatly reducing the energy consumption and relieving the environment pollution.

Owner:长沙紫宸科技开发有限公司

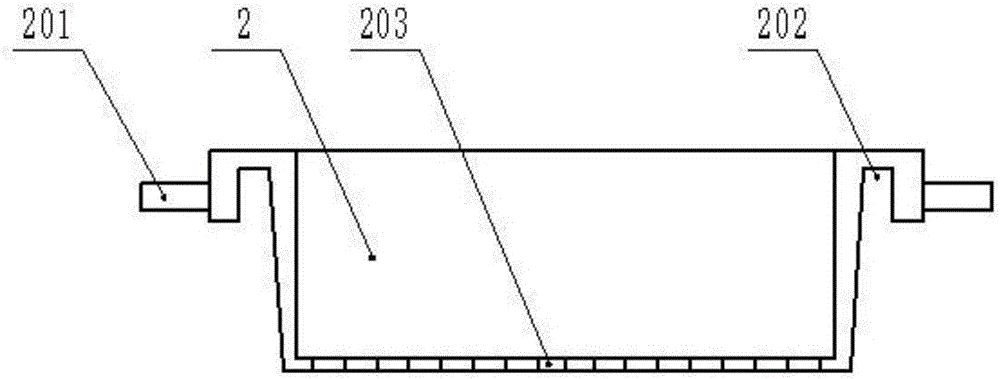

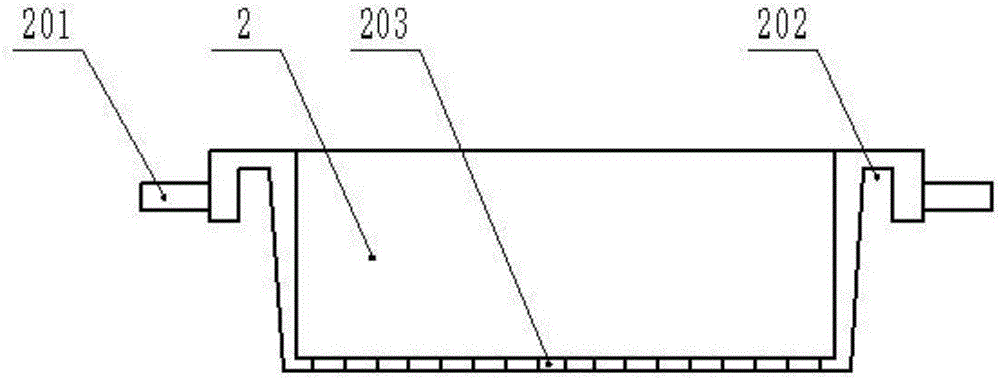

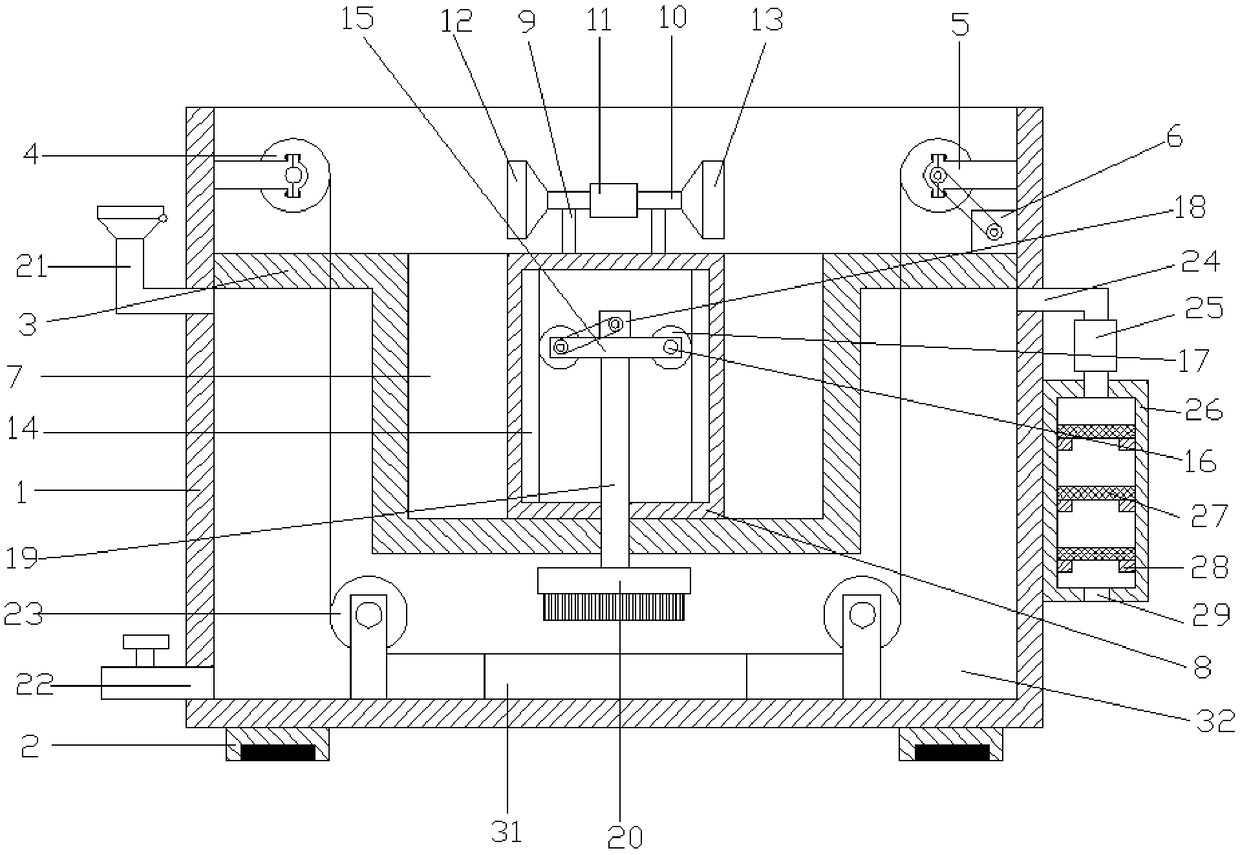

Energy-saving environmentally-friendly duck egg cleaning machine

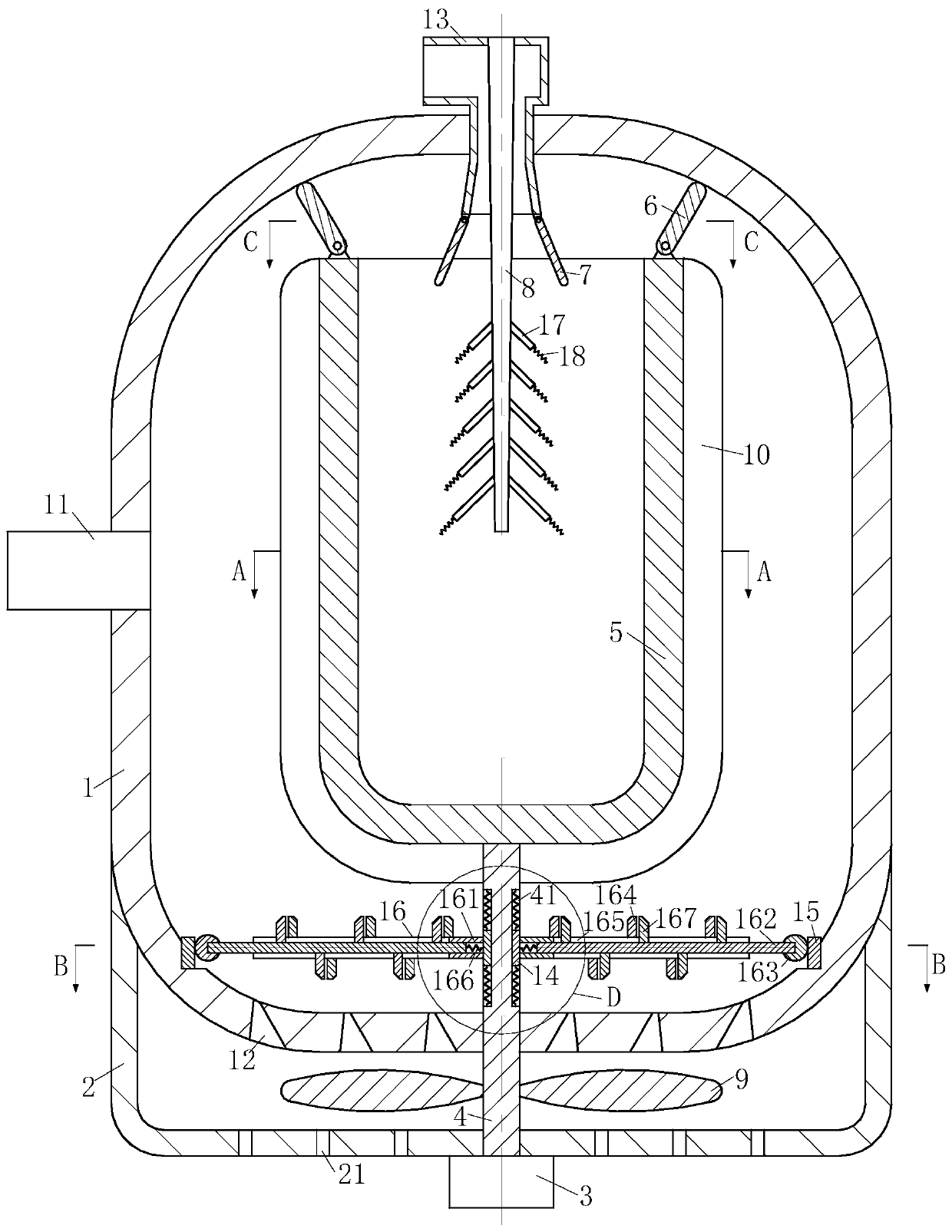

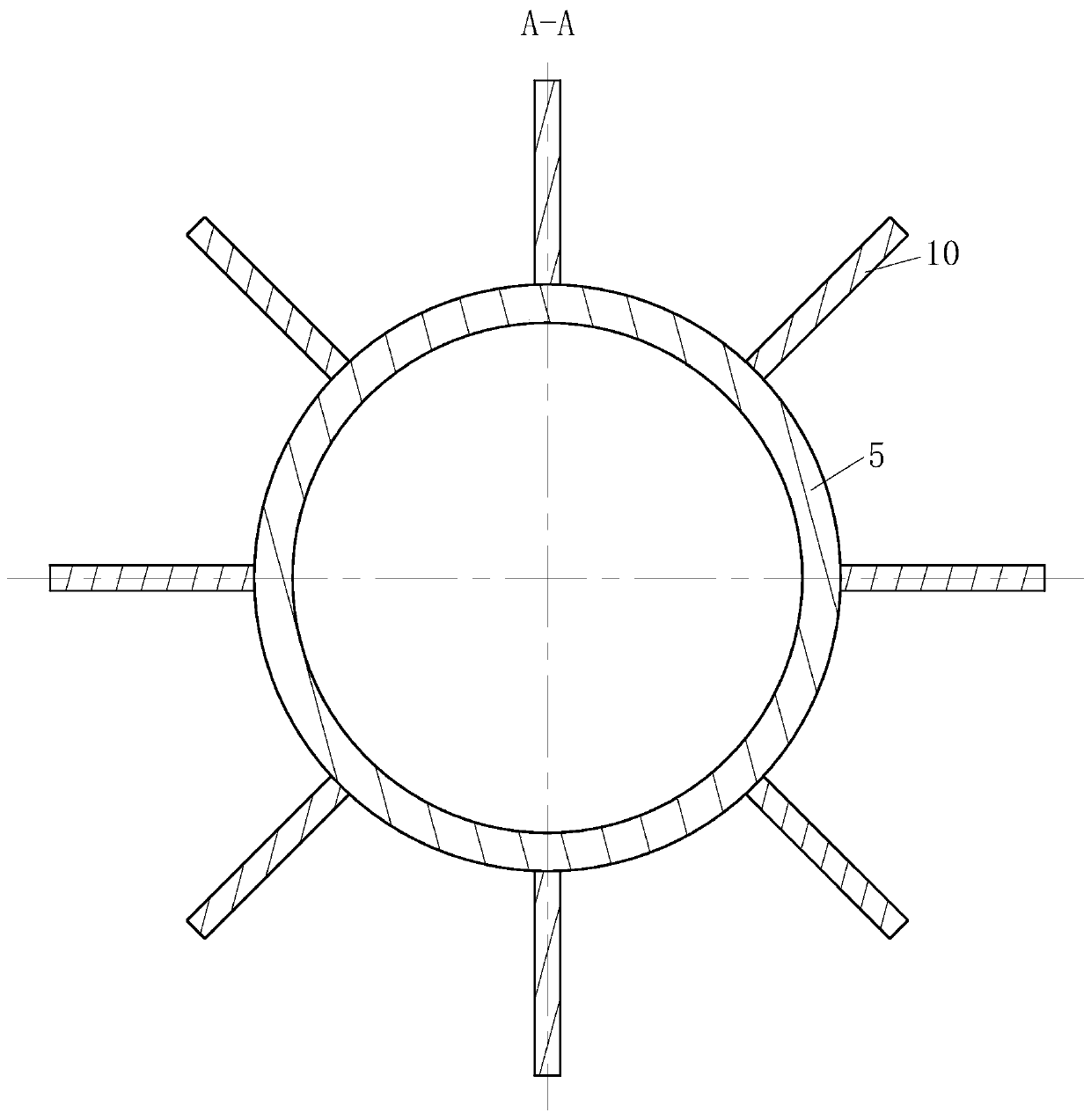

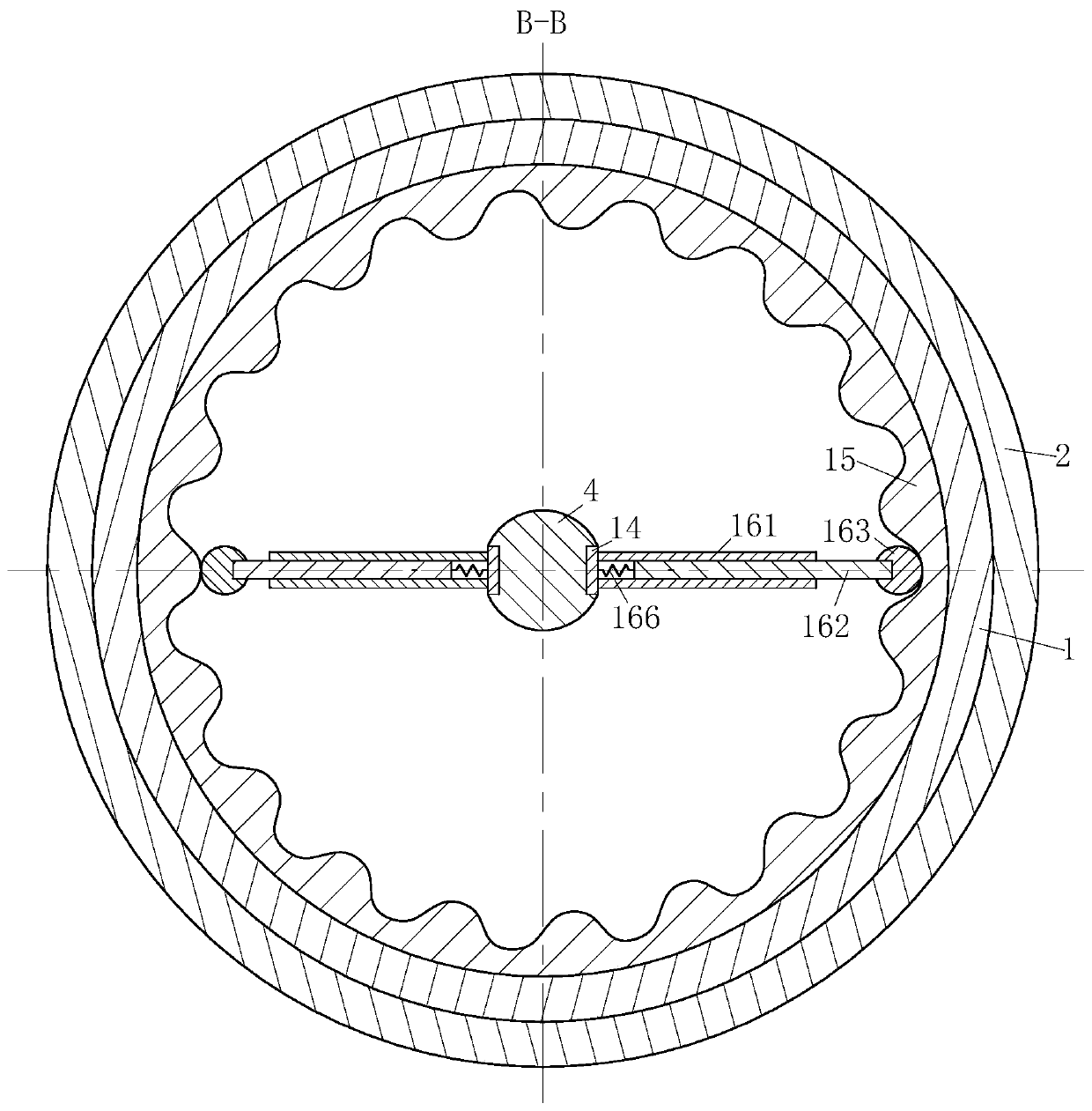

The invention discloses an energy-saving and environment-friendly duck egg cleaning machine, which comprises a cylinder body, an inner container, a rotating chassis, a cross arm, a water pump, a water tank, a primary sedimentation tank, an anaerobic hydrolysis tank, a regulating tank, a filter chamber and a flow valve; The bottom of the body is provided with feet, and the inner bottom of the cylinder is provided with a rotating chassis. The lower end of the rotating chassis is connected to the central rotating shaft, and the central rotating shaft extends downward through the cylinder to connect to the reducer. The reducer is connected to the motor, and the motor is fixed on the supporting feet; The upper end of the chassis is provided with a brush, and the top of the brush is set correspondingly to the inner tank; the uppermost edge of the inner tank is provided with a fixed card slot, and the fixed card slot is arranged in cooperation with the outer wall of the cylinder; a handle is provided on the outer side of the inner tank, and There is a placement groove at the bottom of the liner, wherein the bottom of the placement groove is hollowed out, and the placement groove is located directly above the brush; the invention has the advantages of simple structure, convenient use, easy cleaning, long service life, energy saving and environmental protection, good cleaning effect, and high working efficiency High, reducing production costs.

Owner:SUQIAN HUAIHAI TECH SERVICES

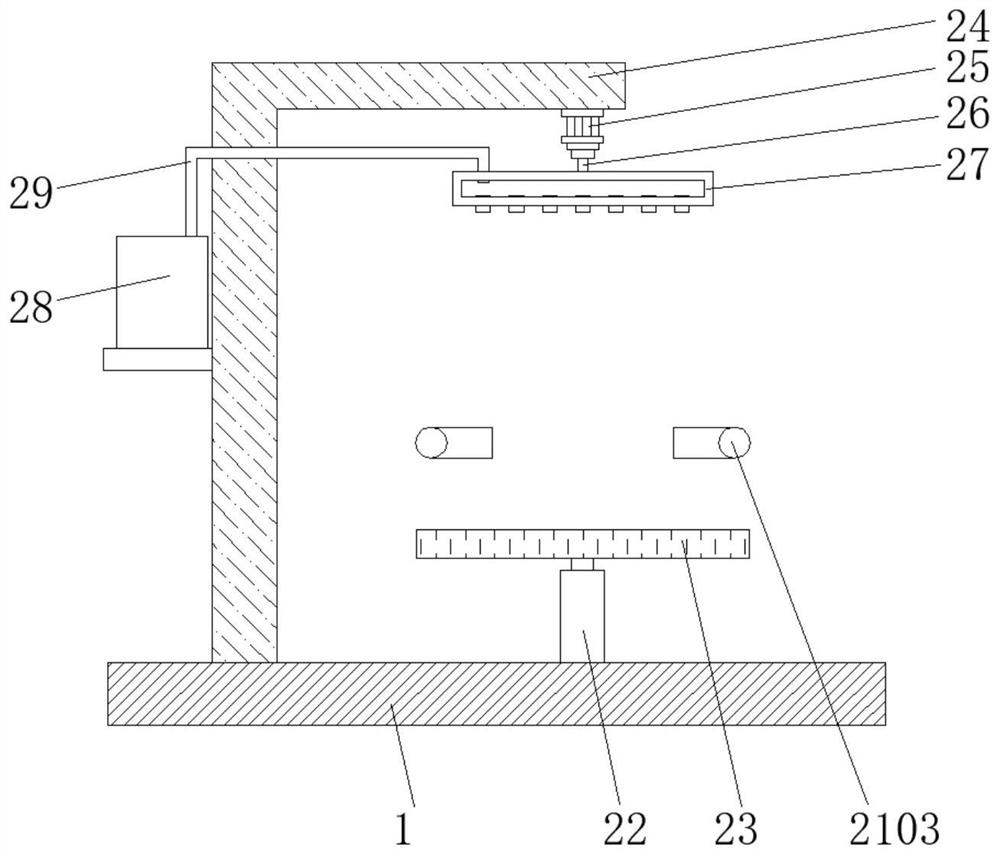

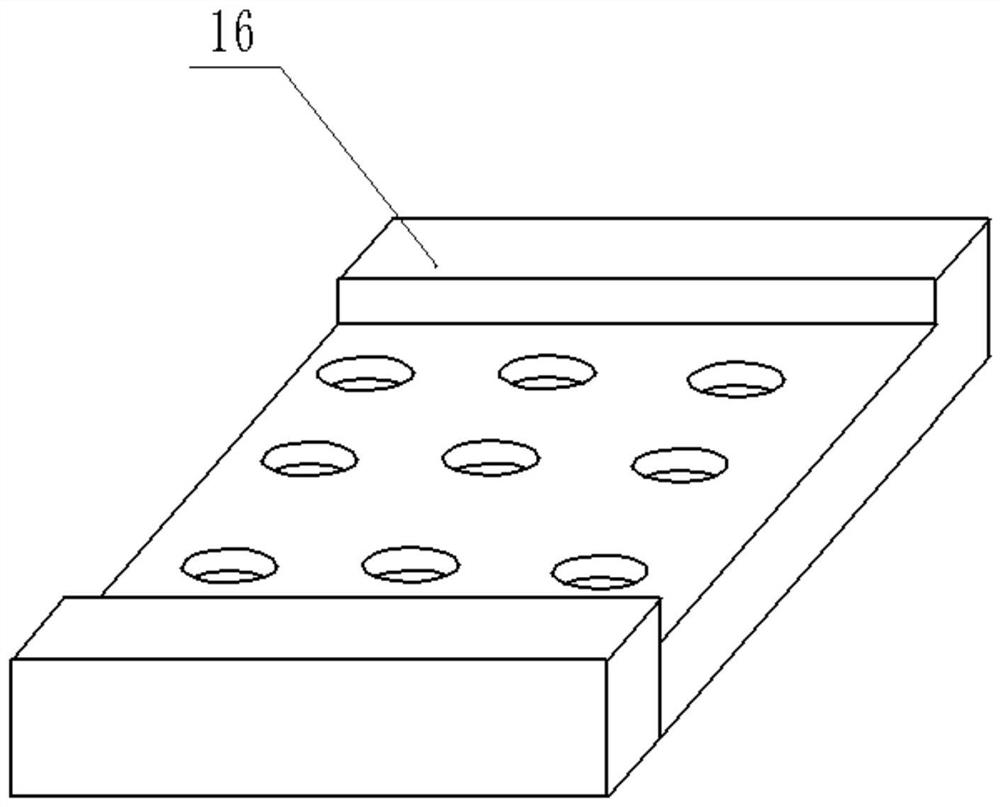

Cleaning machine

The invention discloses a cleaning machine which comprises a cylinder body, an inner container, a rotary bottom plate, a transverse arm, a water pump, a water tank, a biological reaction tank, a water processing tank and a water purifying tank. Supporting legs are arranged at the bottom of the cylinder body. The rotary bottom plate is arranged at the bottom end in the cylinder body. The lower end of the rotary bottom plate is connected with a central rotating shaft. The central rotating shaft penetrates through the cylinder body and extends downwards to be connected with a speed reducer. The speed reducer is connected with a motor which is fixed to the supporting legs. A brush is arranged at the upper end of the rotary bottom plate. The upper portion of the brush corresponds to the inner container. The edge of the uppermost end of the inner container is provided with a fixed clamping groove which is matched with the outer wall of the cylinder body. A handle is arranged on the outer side of the inner container. A placement groove is formed in the bottom of the inner container. The bottom of the placement groove is hollowed out. The placement groove is located over the brush. The transverse arm is arranged over the inner container. The cleaning machine is simple in structure, convenient to use, easy to clean, long in service life, capable of saving energy, environmentally friendly, good in cleaning effect and high in work efficiency, and production cost is reduced.

Owner:SUQIAN HUAIHAI TECH SERVICES

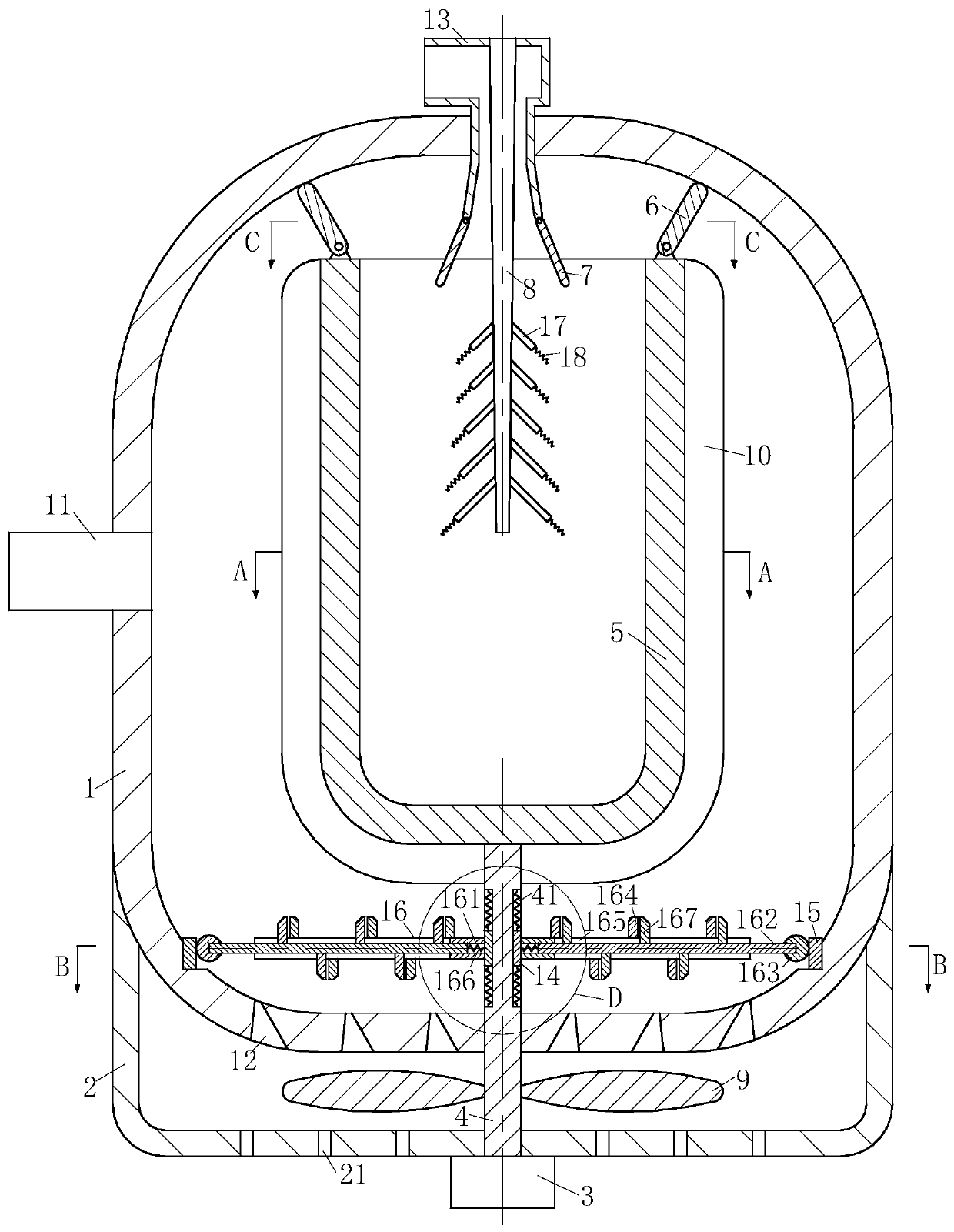

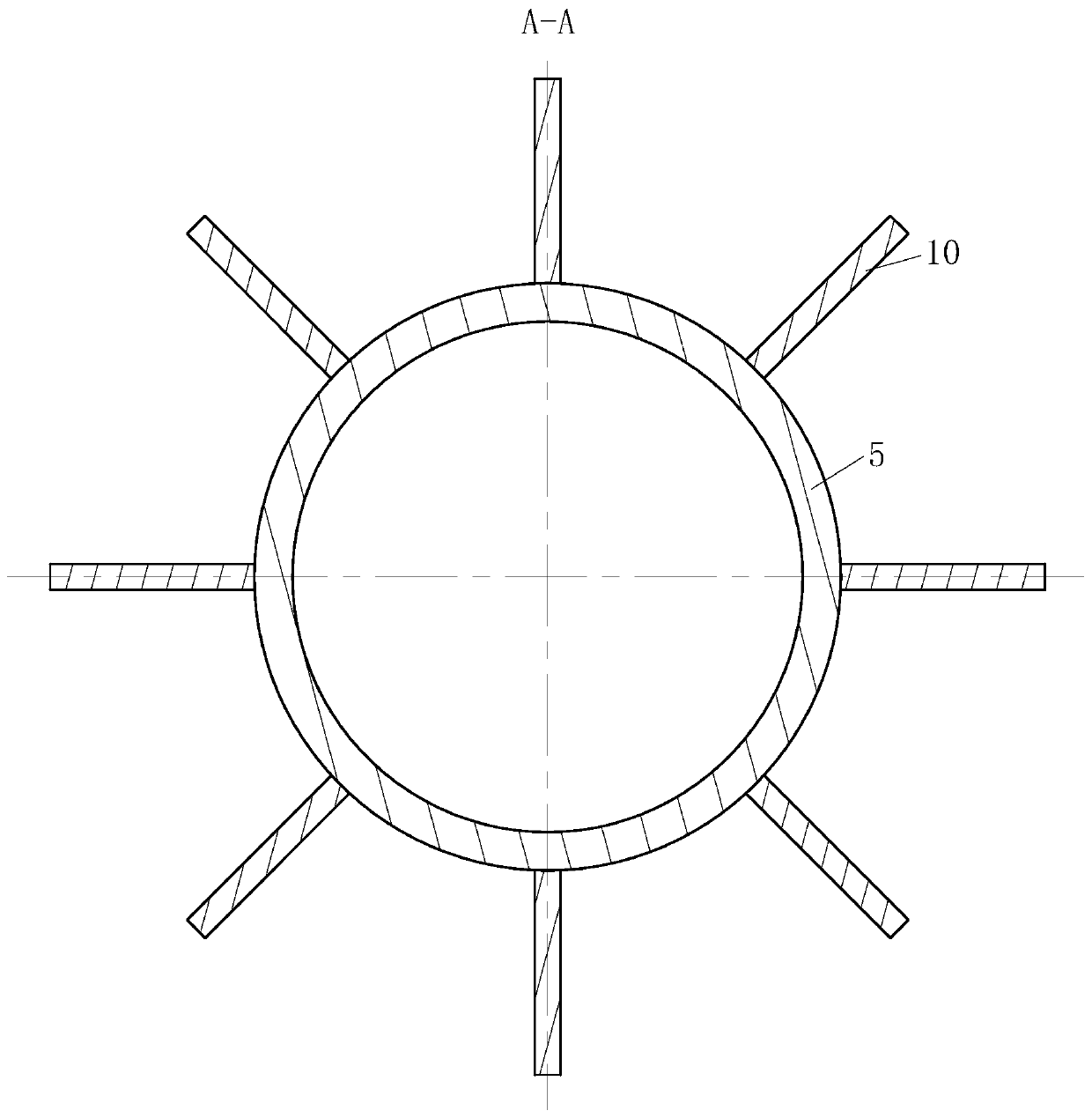

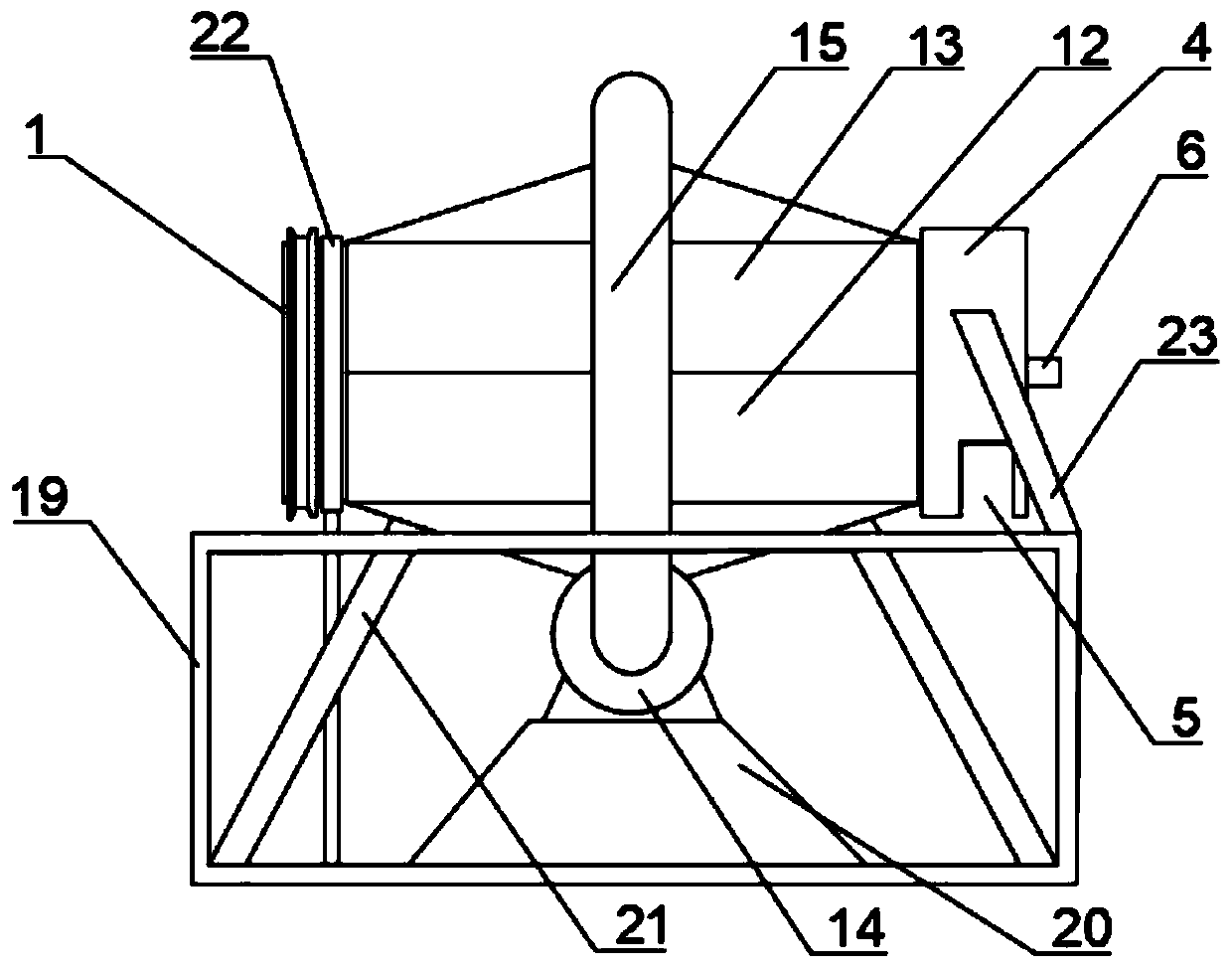

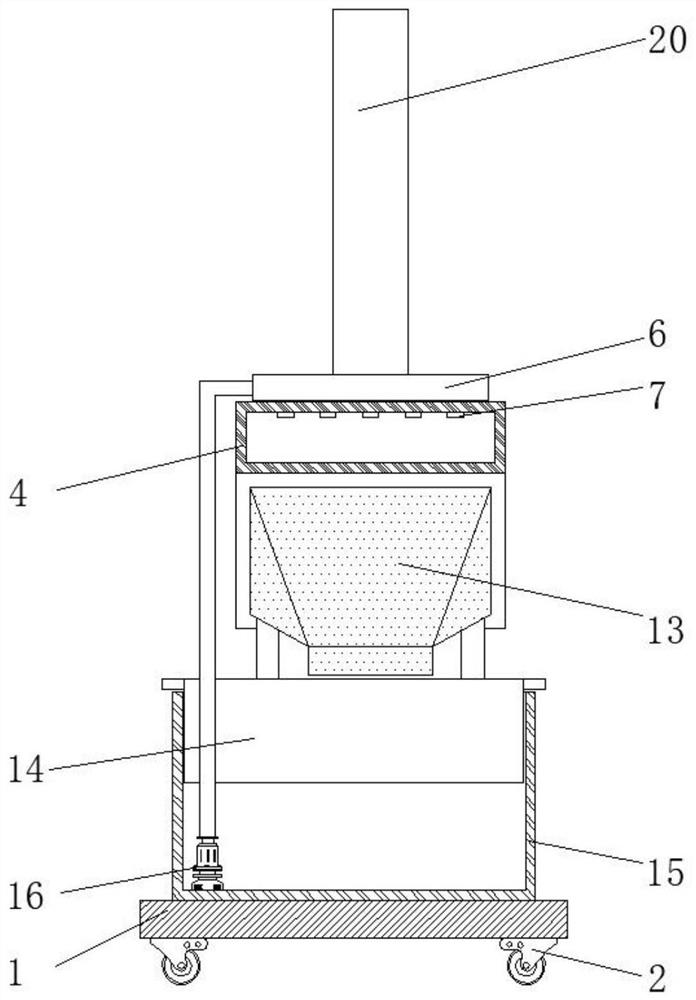

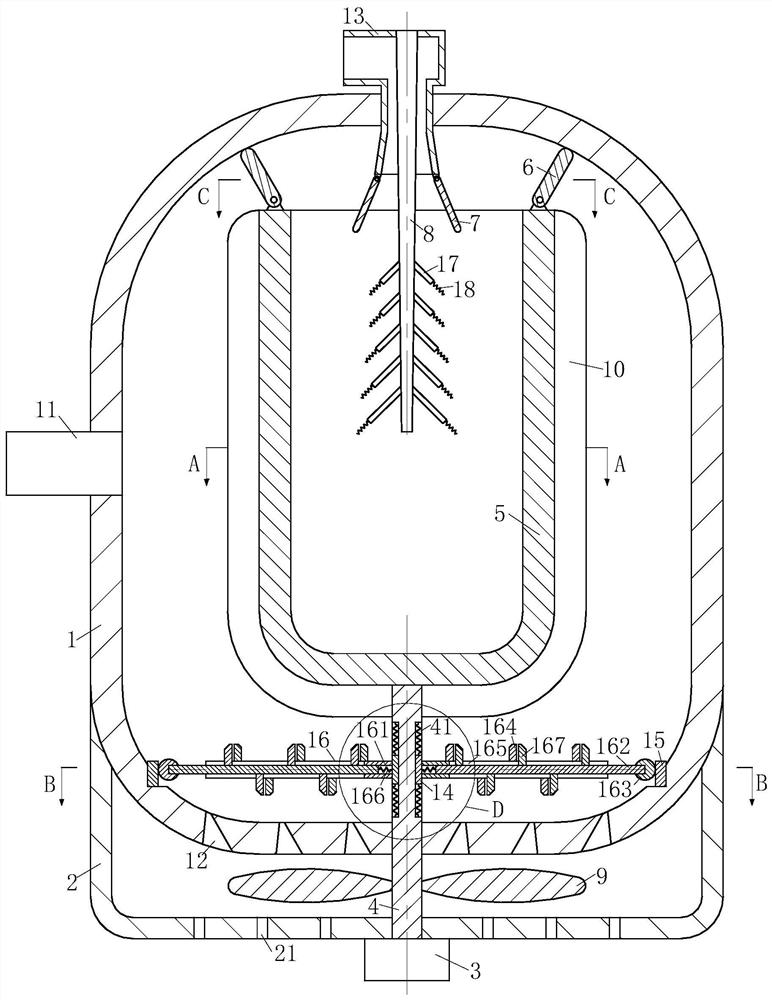

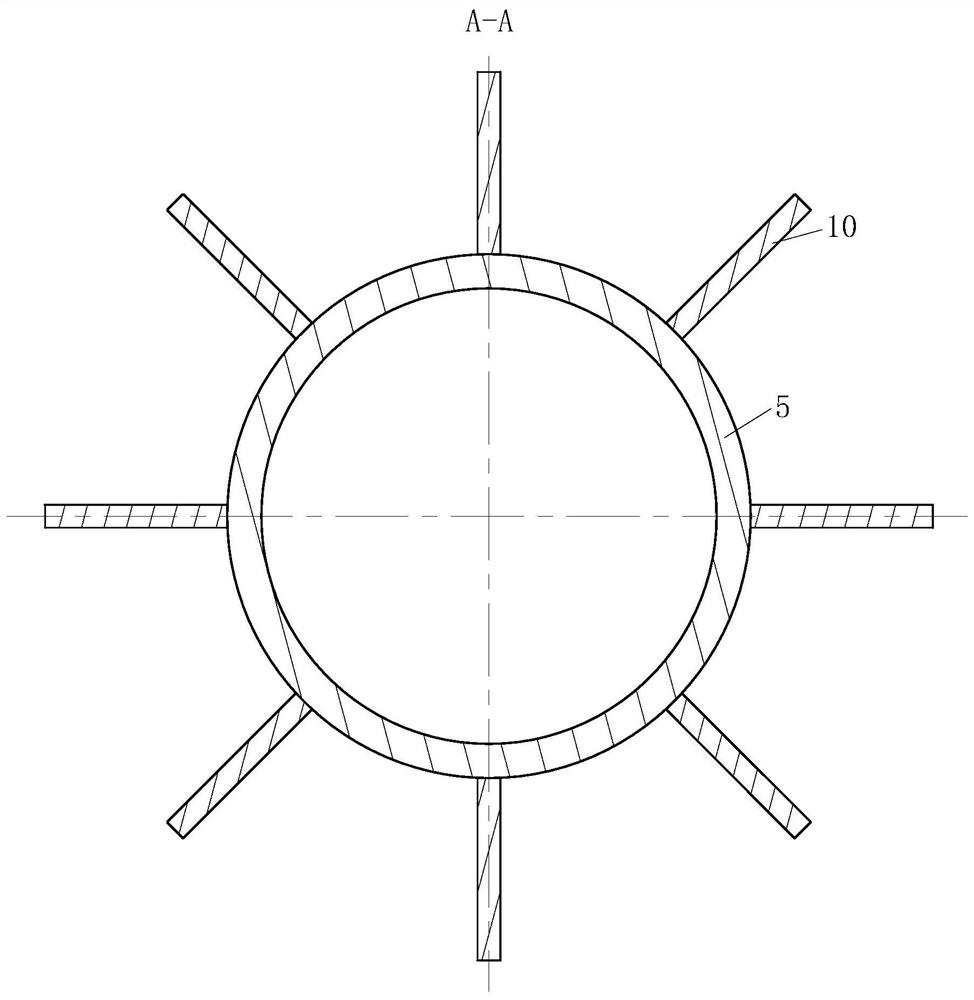

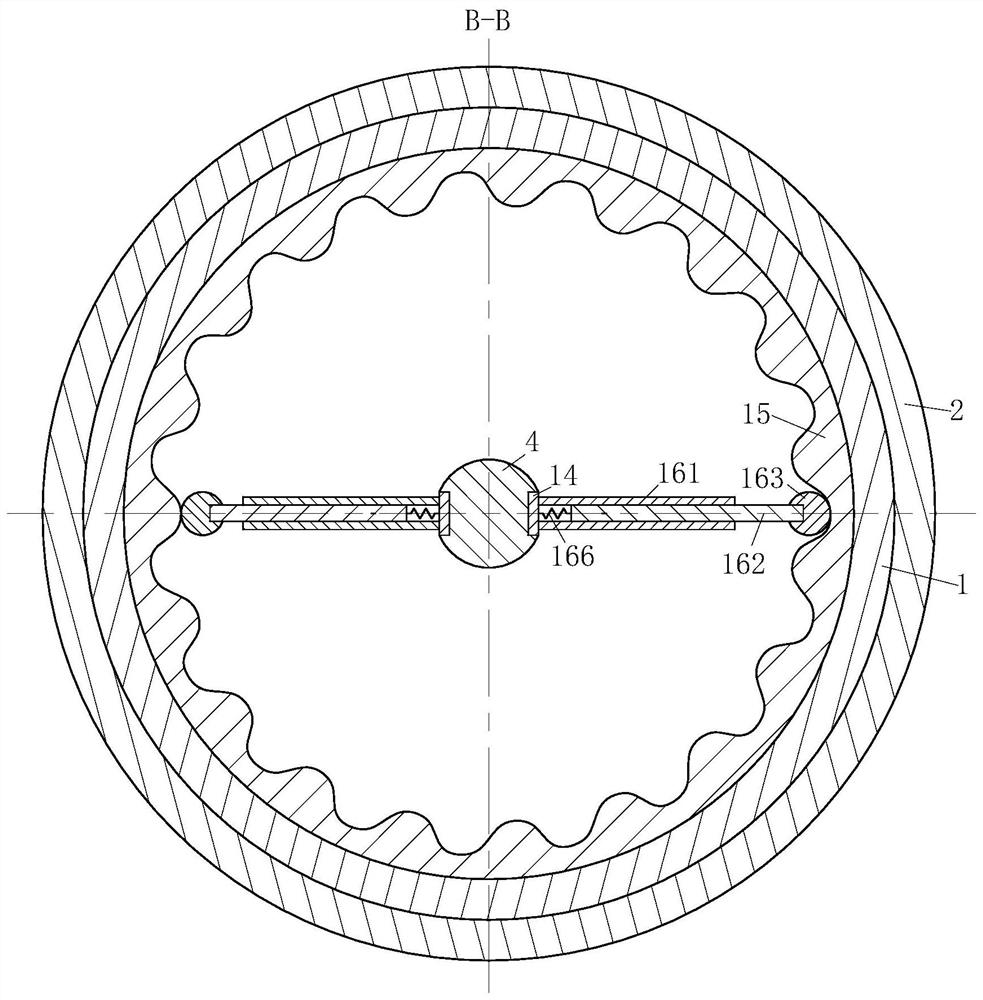

Domestic waste incinerator based on wind power transmission

The invention relates to the technical field of incineration equipment, in particular to a domestic waste incinerator based on wind power transmission. The domestic waste incinerator based on the windpower transmission comprises a furnace body, a base, a motor, a transmission shaft, a combustion chamber, a feeding door, a material blocking plate and an oil supply rod; the base is fixedly connected to the bottom of the furnace body, and a plurality of air inlet holes are formed in the base; and the motor is fixedly connected to the middle of the lower end of the base; the lower end of the transmission shaft is fixedly connected to a rotating shaft of the motor, a plurality of air blast blades are fixedly connected to the position, near the base, of the transmission shaft, and the upper endof the transmission shaft is fixedly connected to the bottom of the combustion chamber; and the combustion chamber is positioned at the central position of the inner part of the furnace body. According to the domestic waste incinerator based on the wind power transmission, the structure is simple, the usage is convenient, the incineration efficiency is high, domestic waste at the bottom of the furnace body is subjected to stirring and incision by arranging a stirring module, air drying and rising are convenient, the feeding efficiency is improved, and then the incineration efficiency is improved, the domestic waste falling into the combustion chamber is subjected to sufficient and even oil injection by arranging a plurality of successively increasing oil injection rods, the domestic wastecan be burned more fully, and the incineration efficiency can be improved.

Owner:徐州劲硕电气科技有限公司

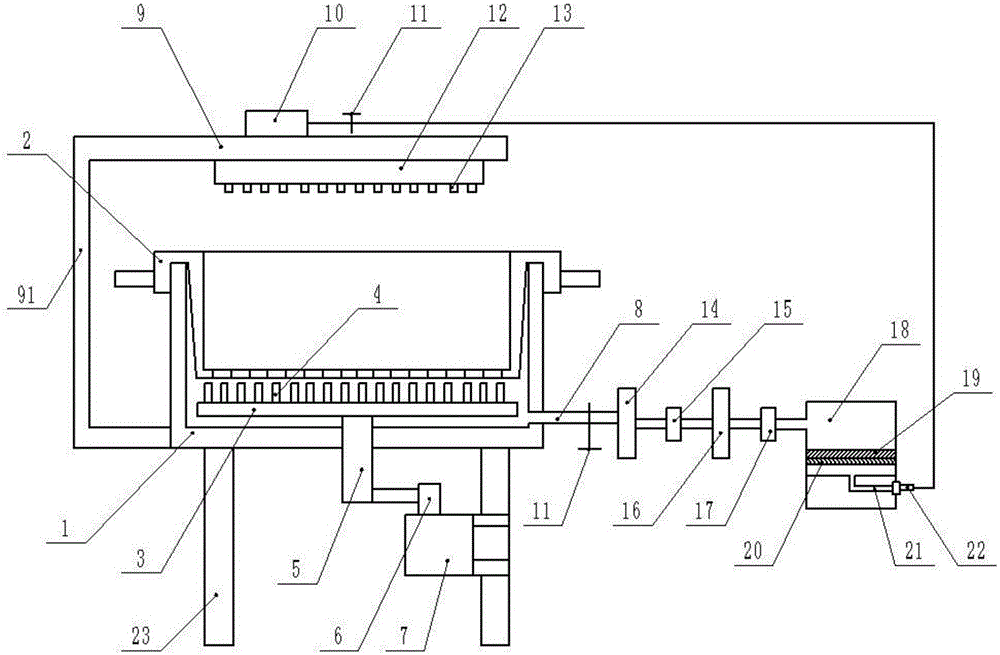

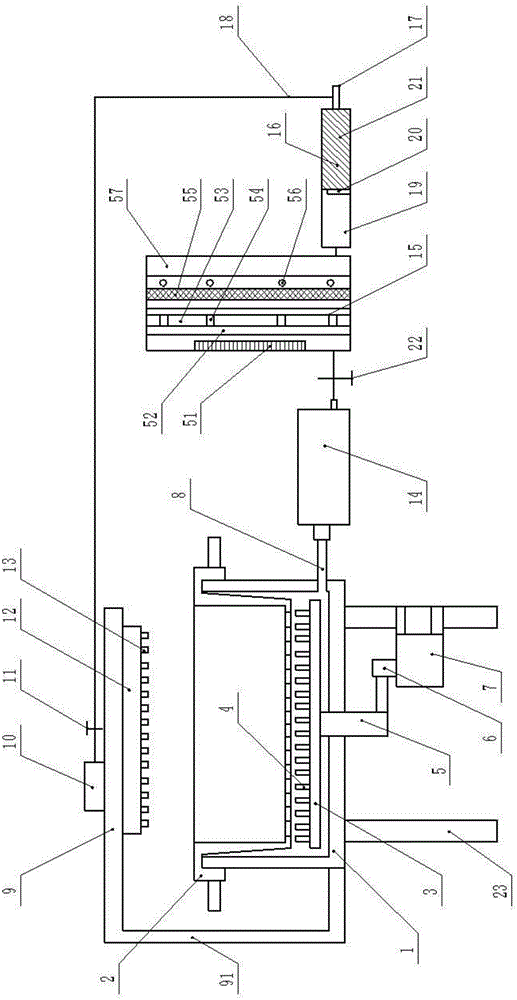

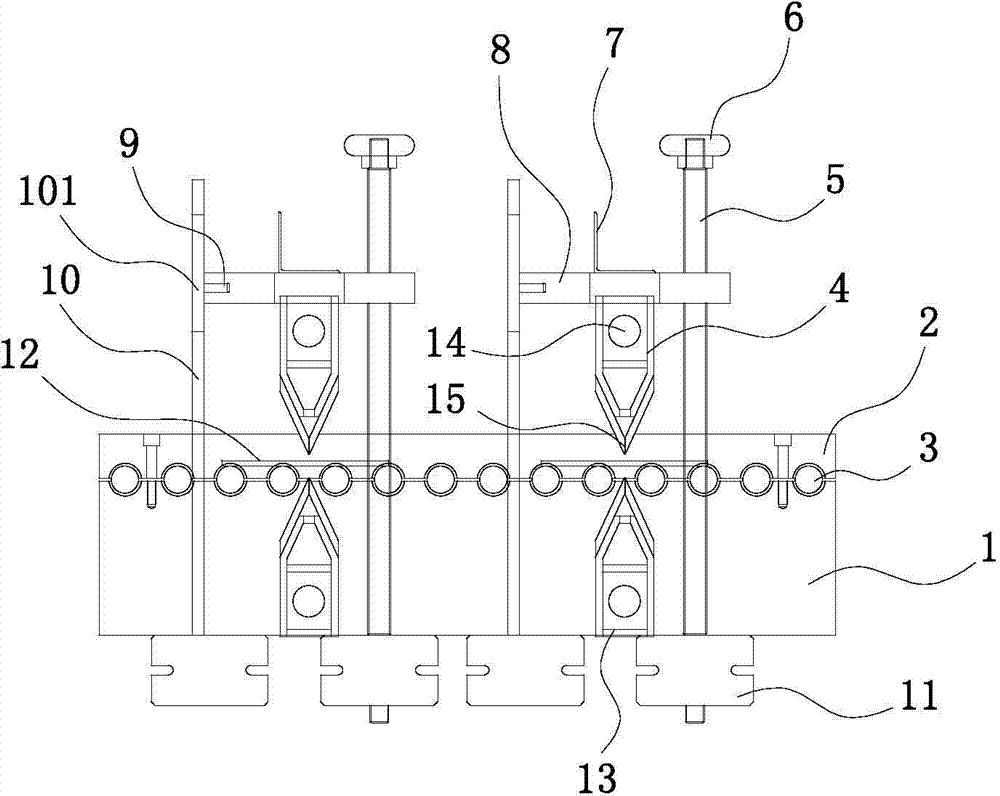

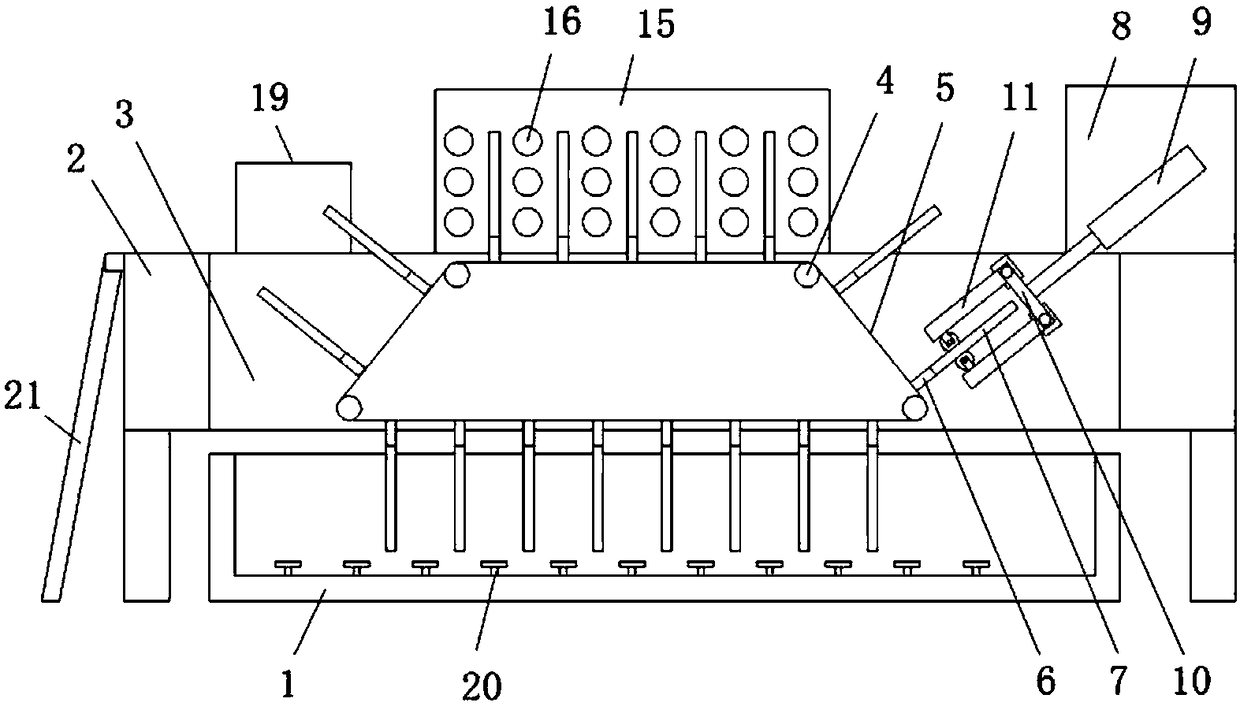

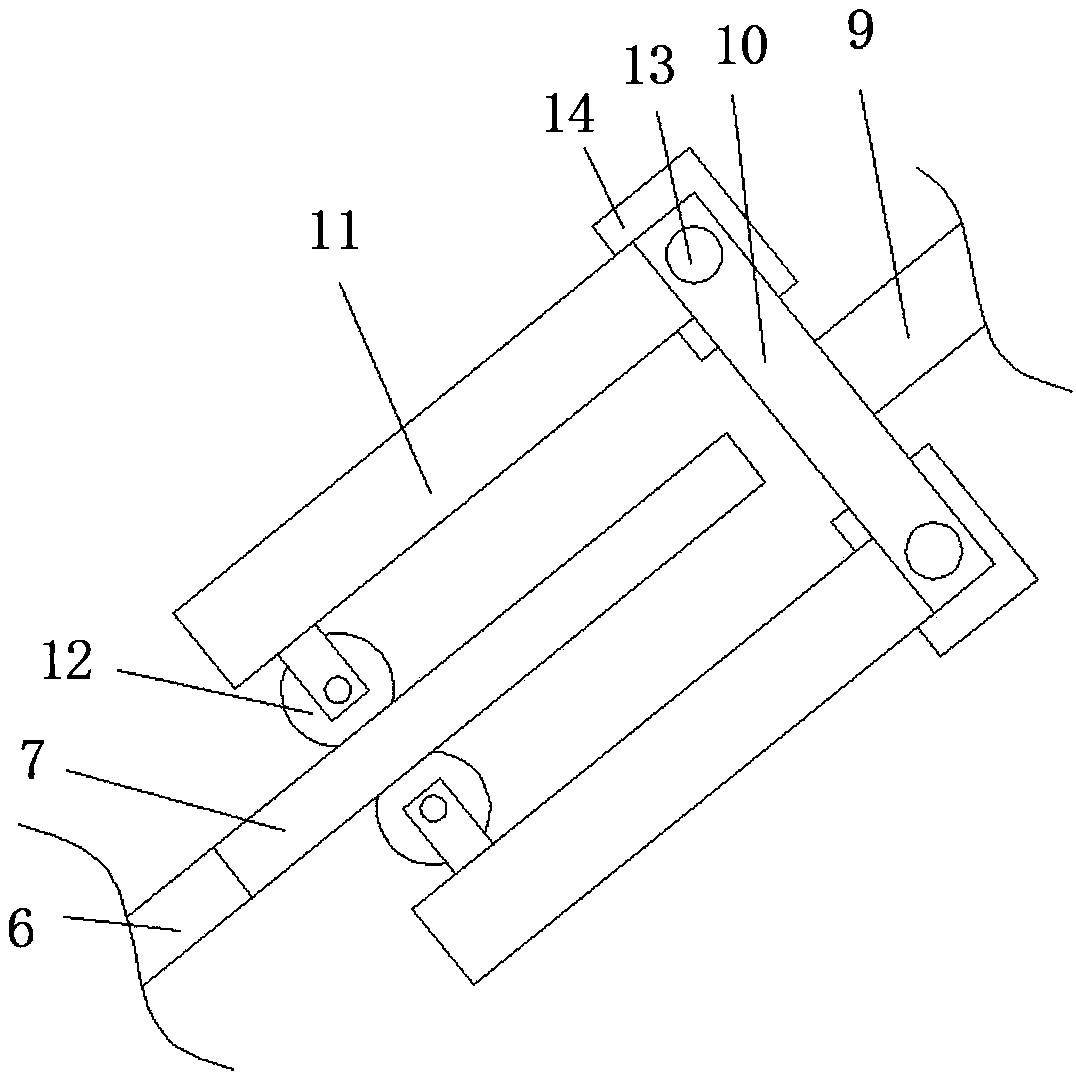

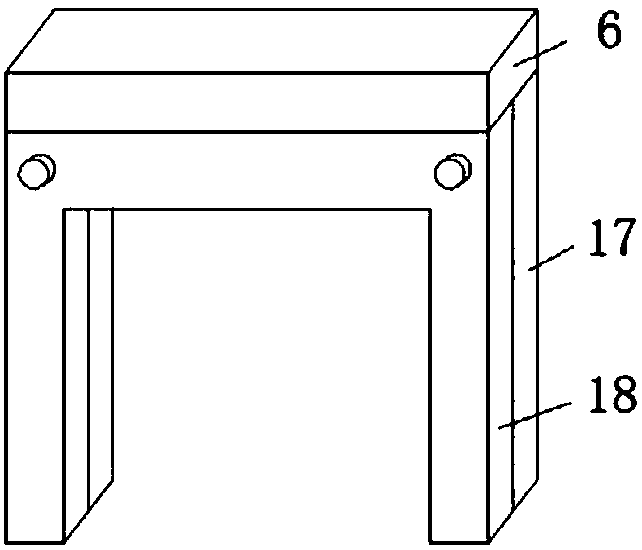

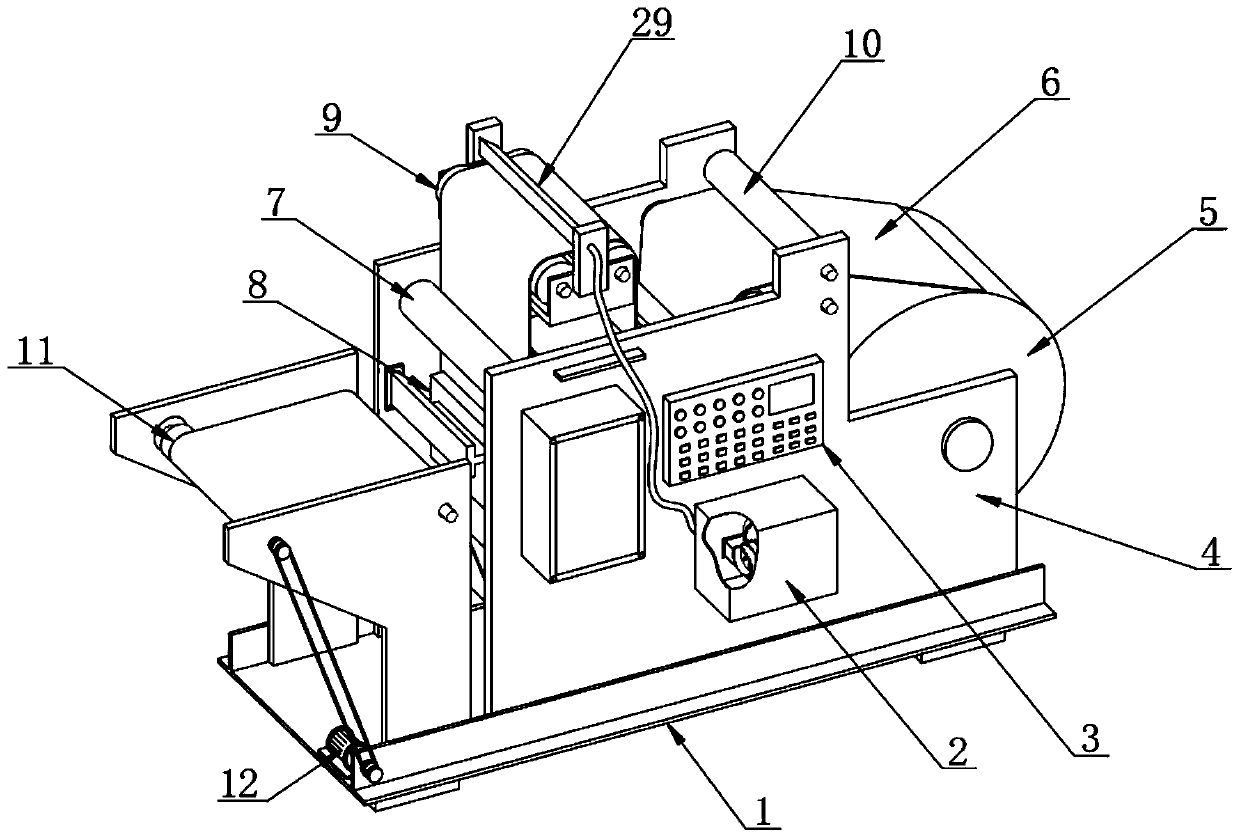

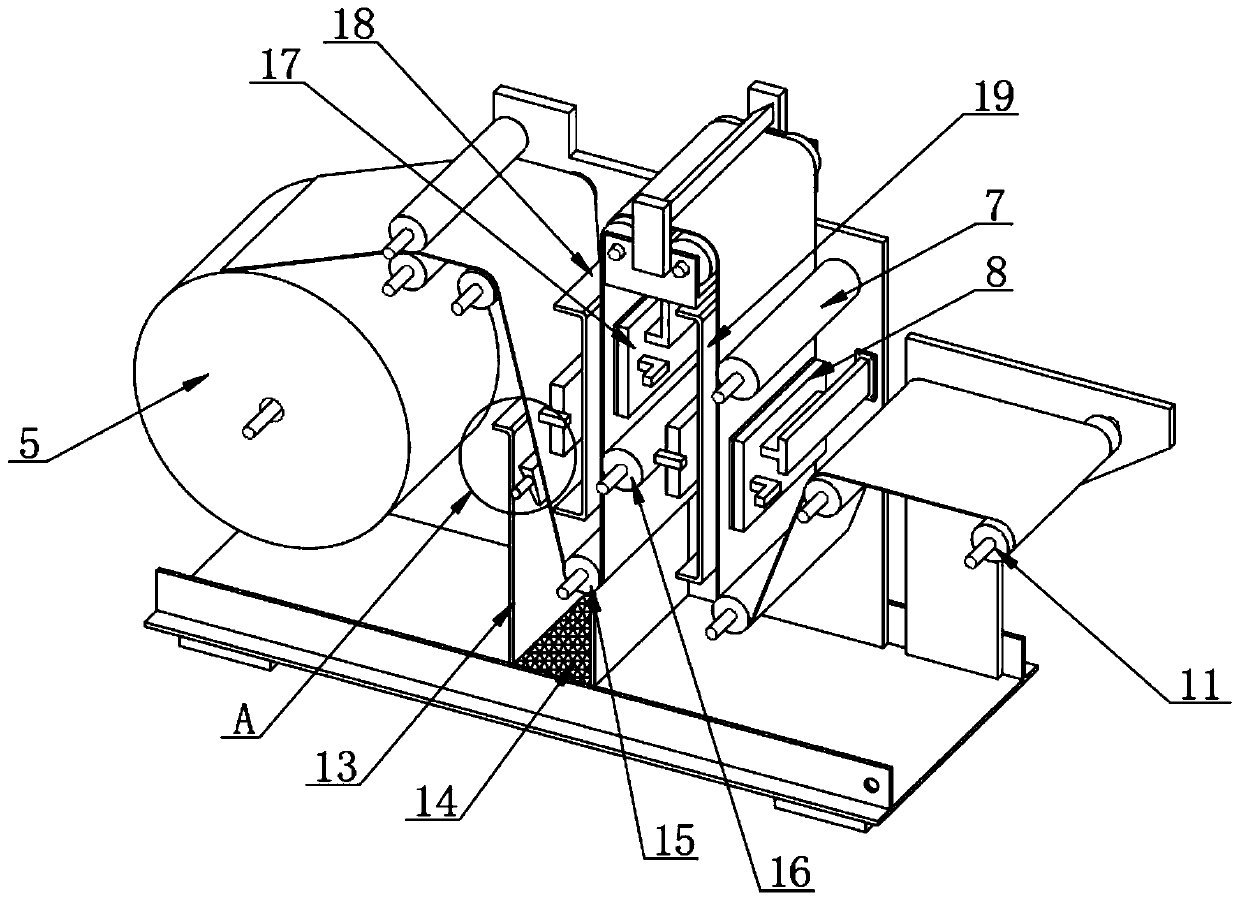

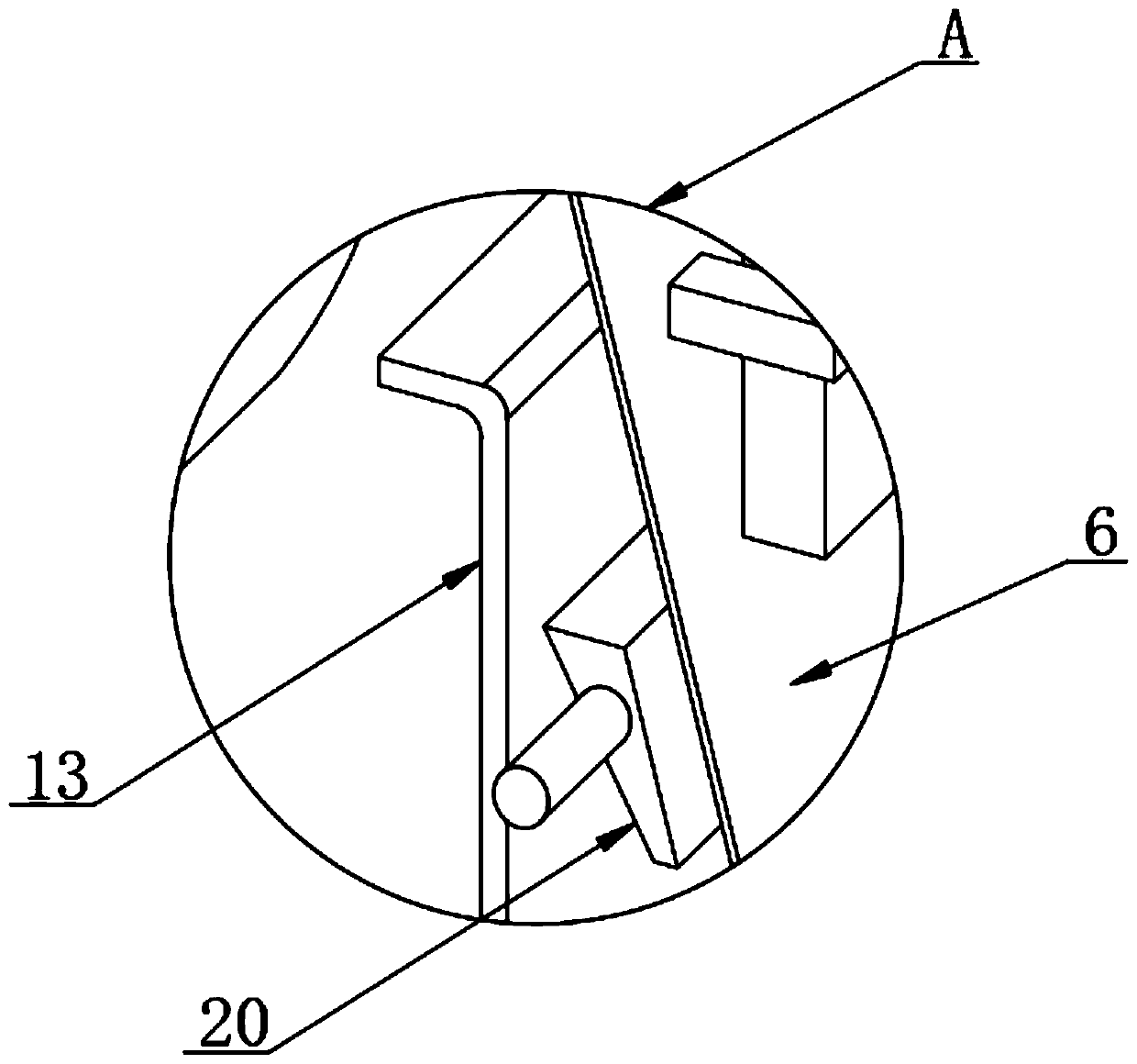

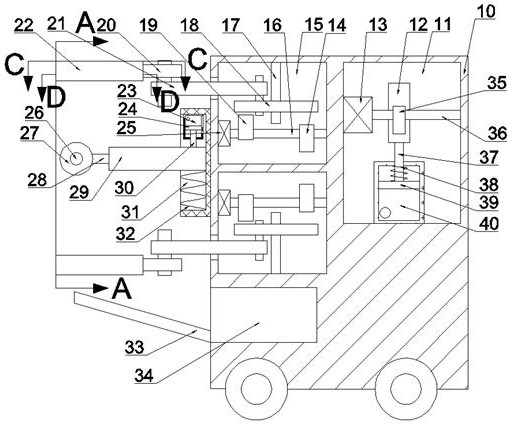

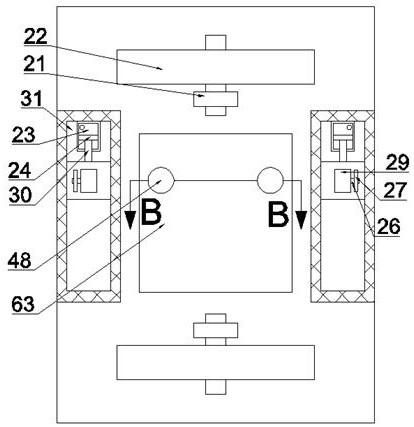

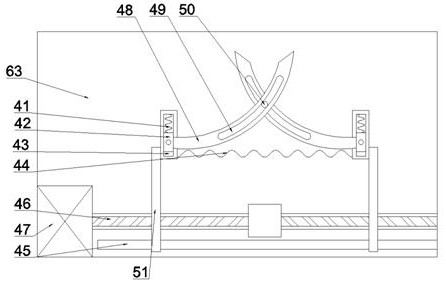

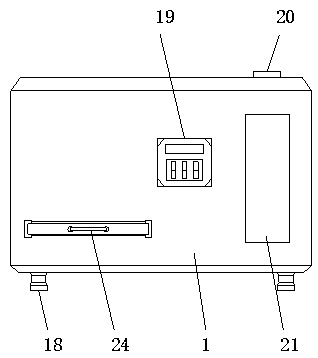

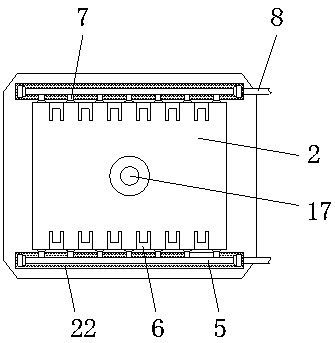

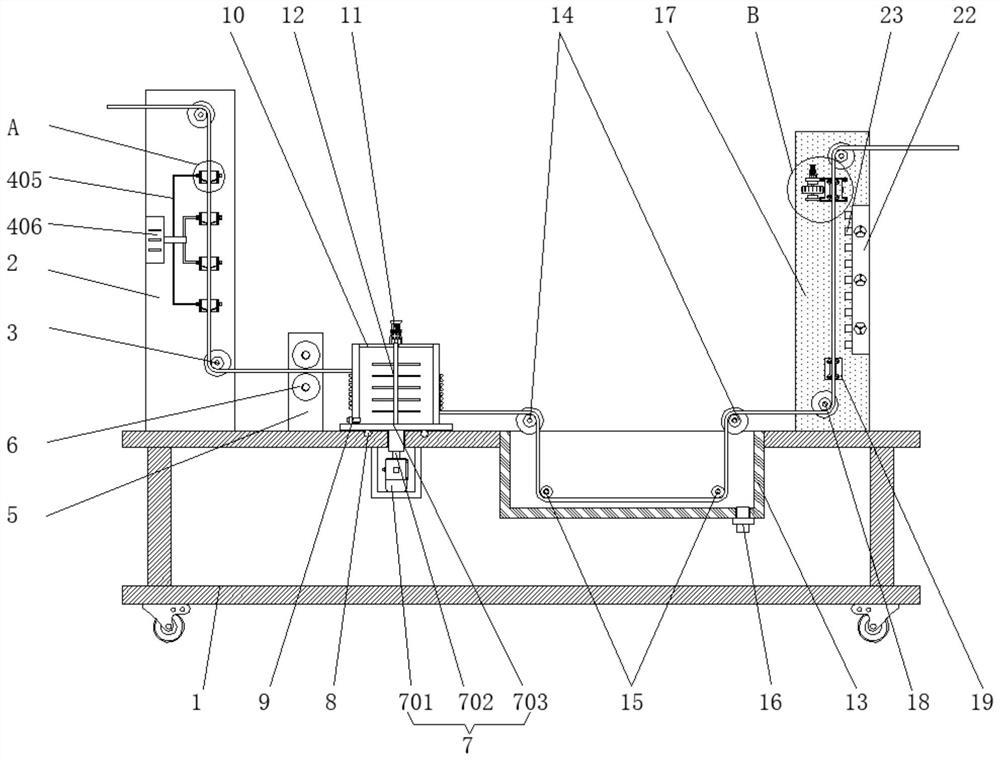

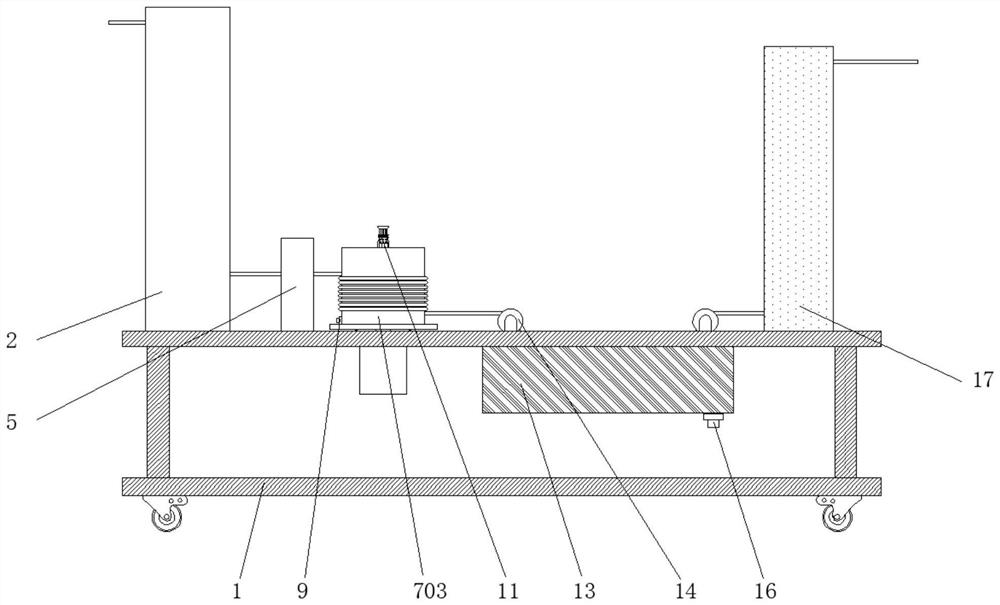

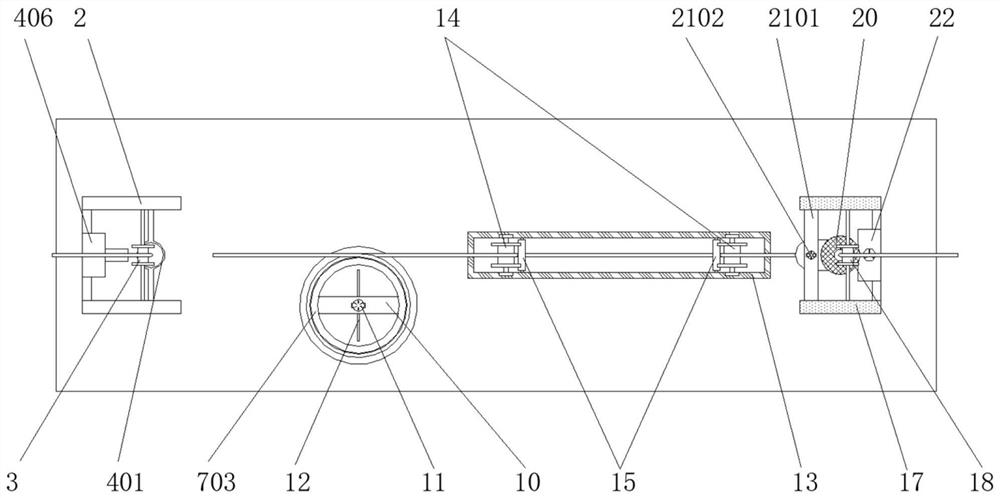

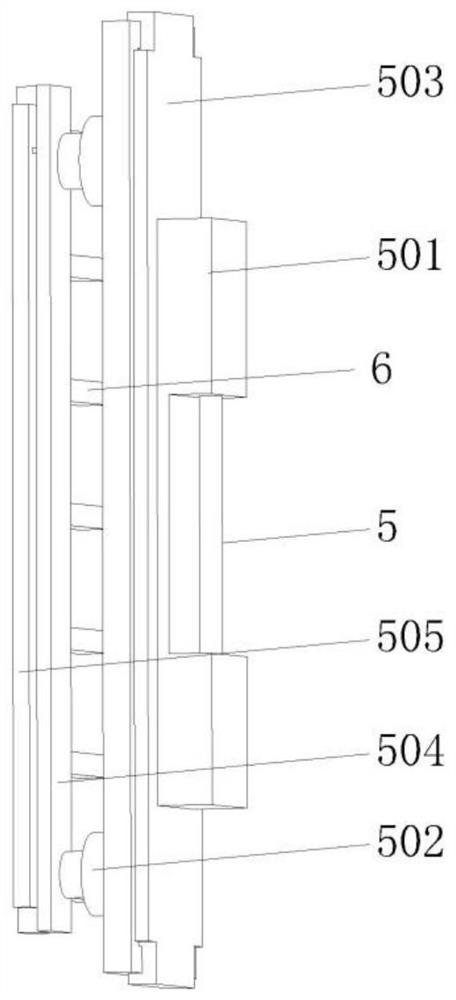

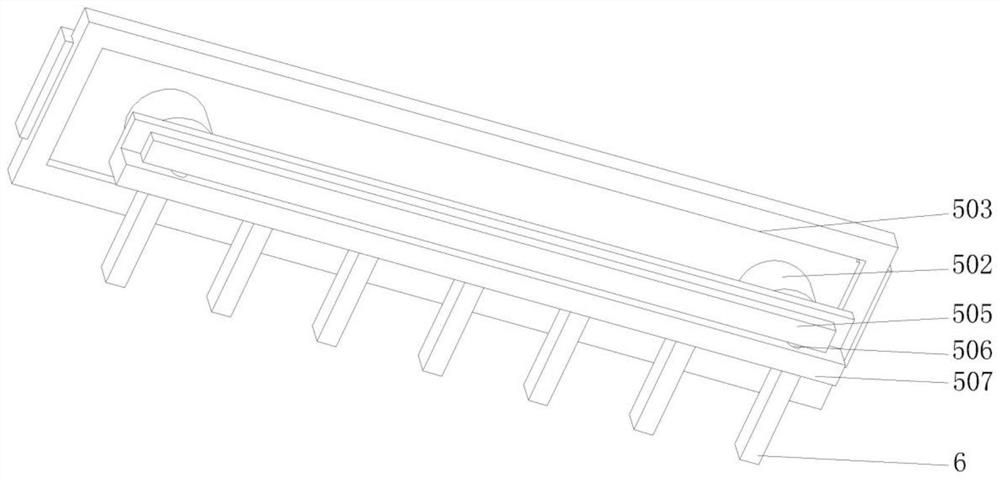

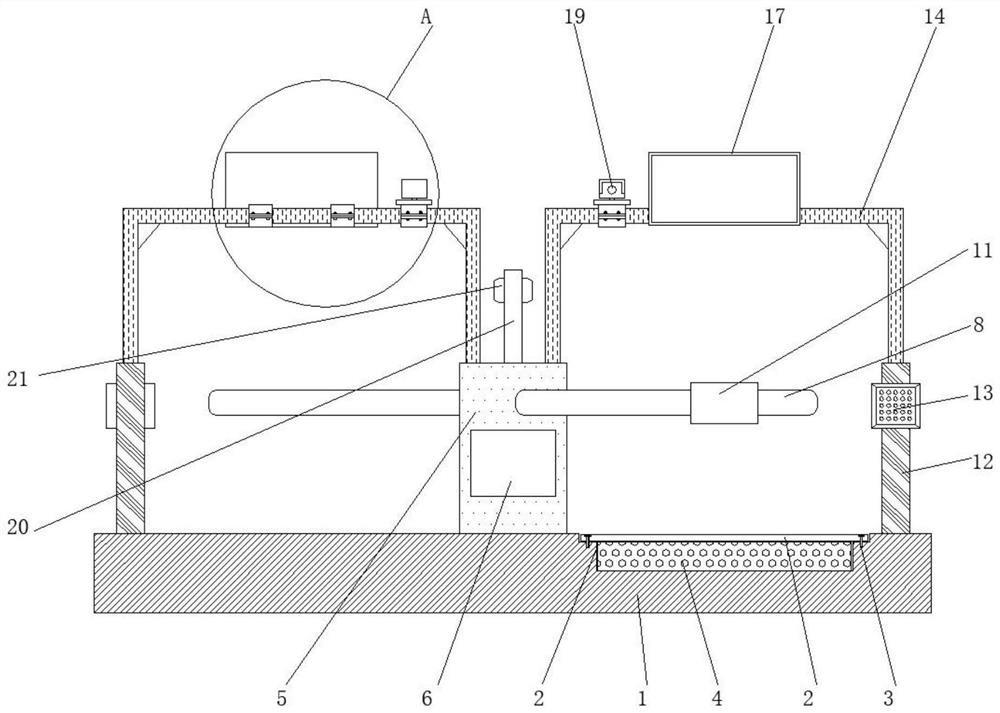

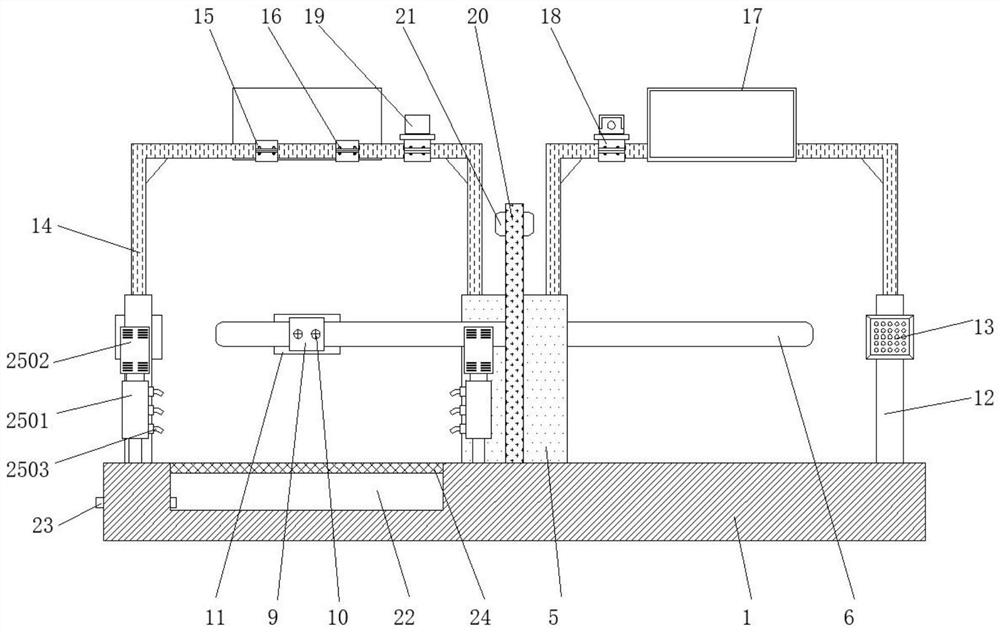

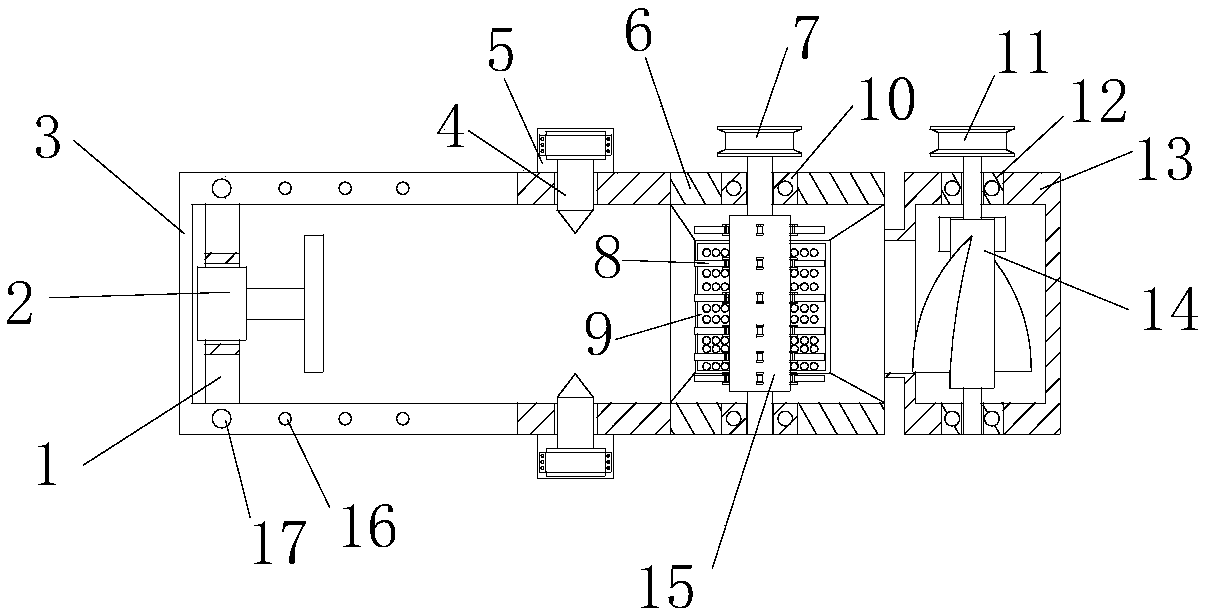

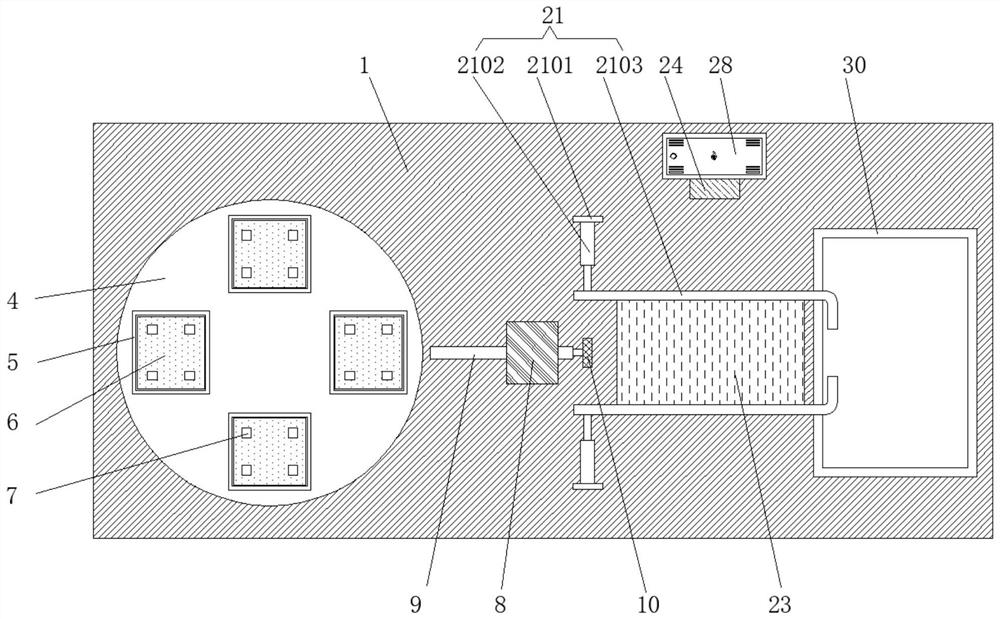

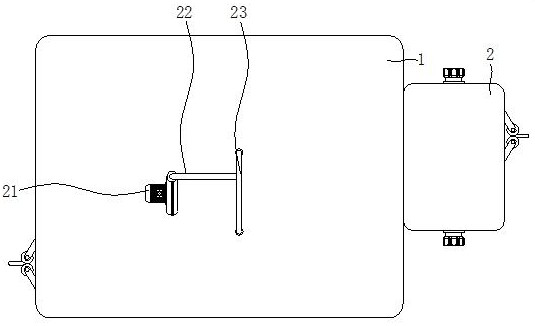

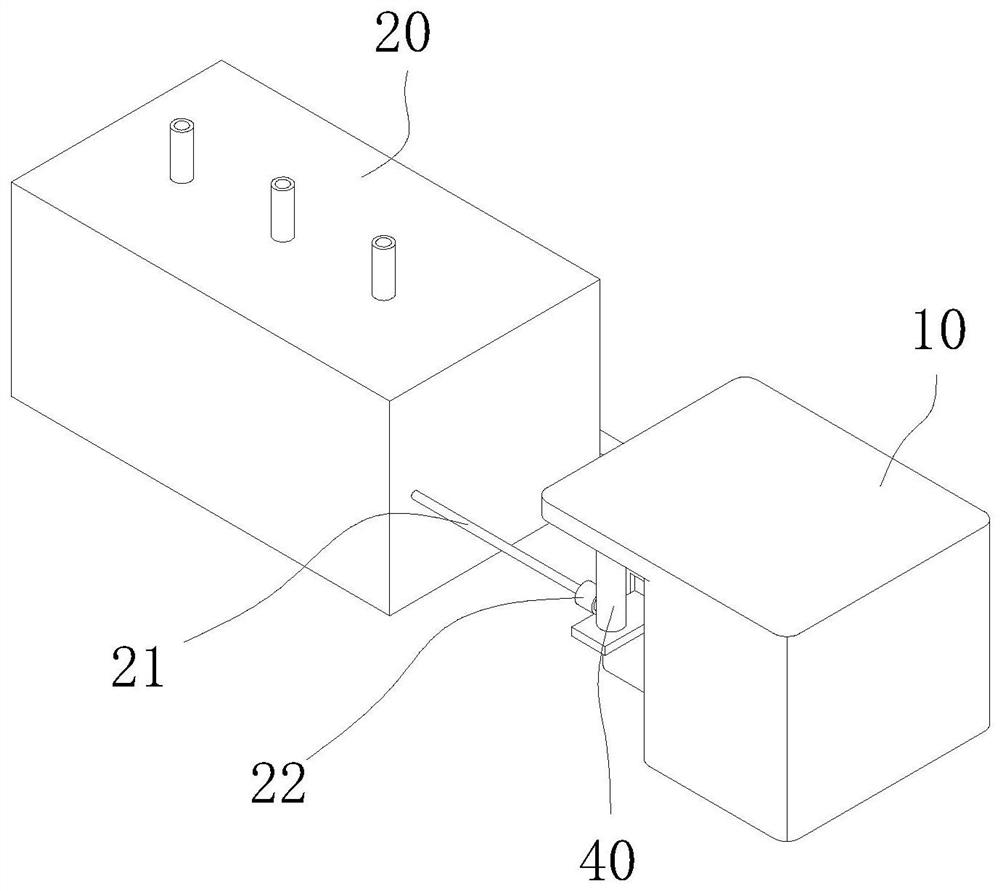

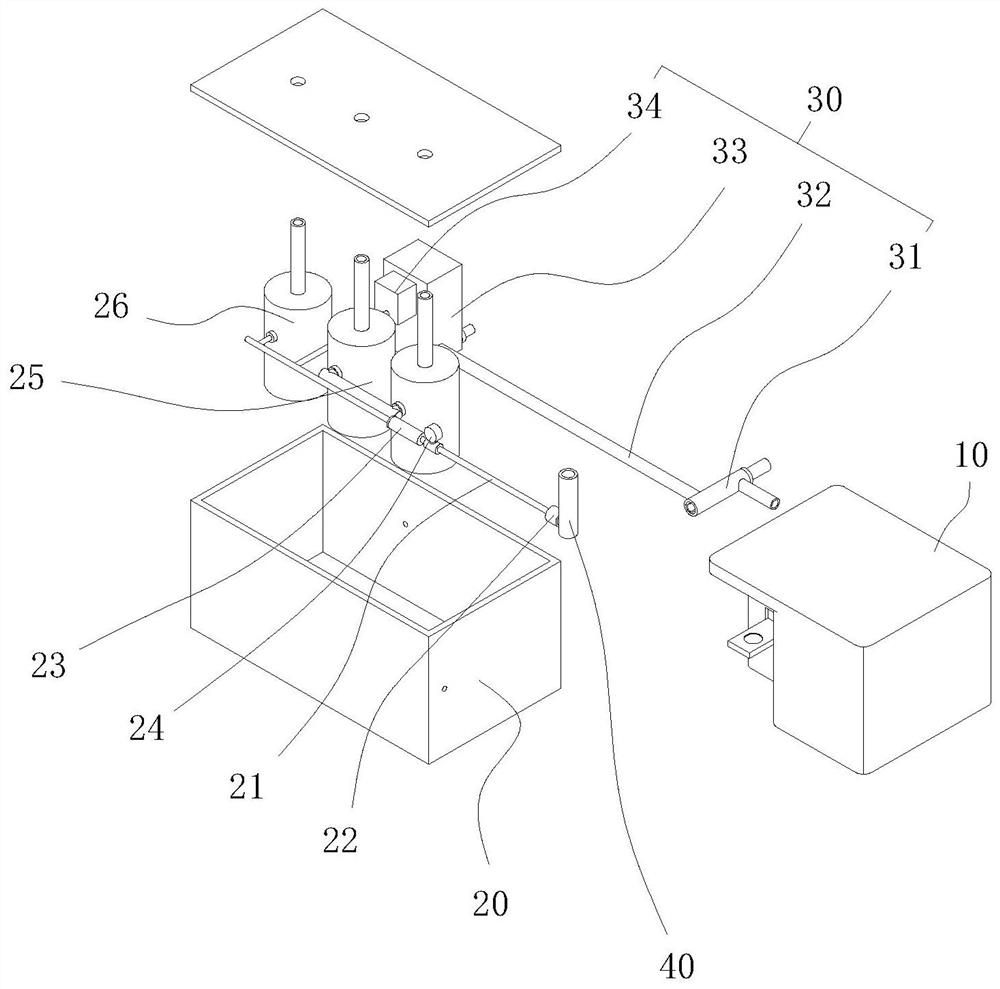

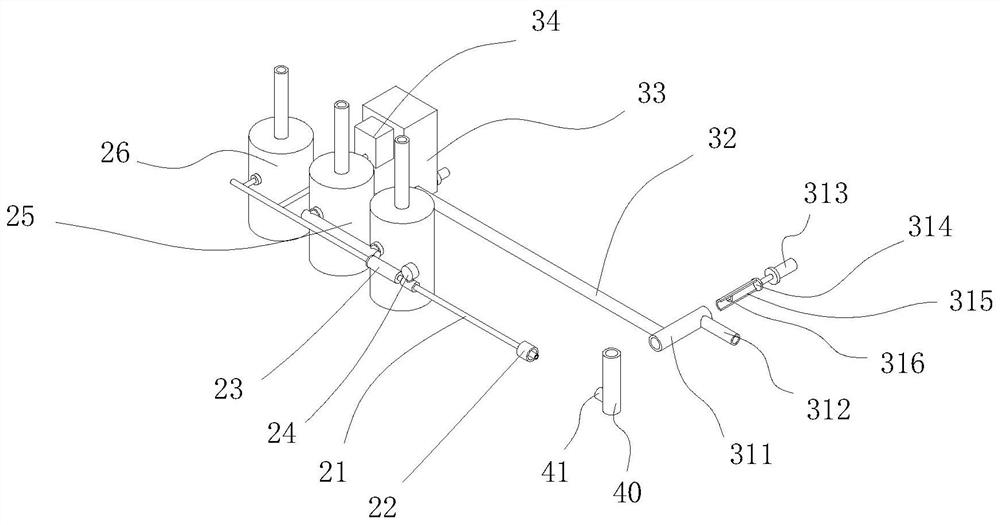

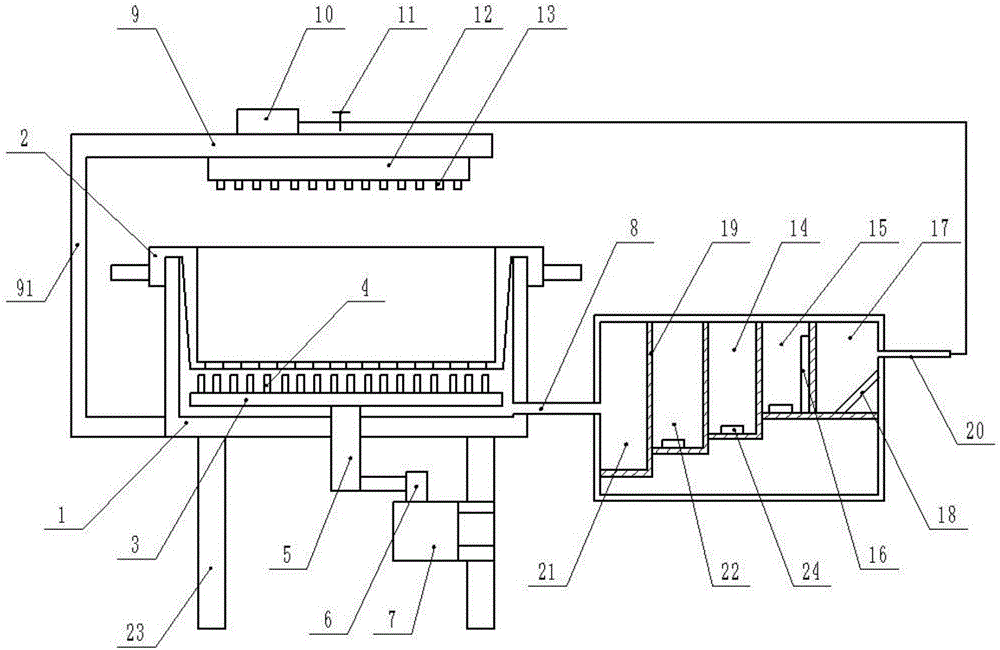

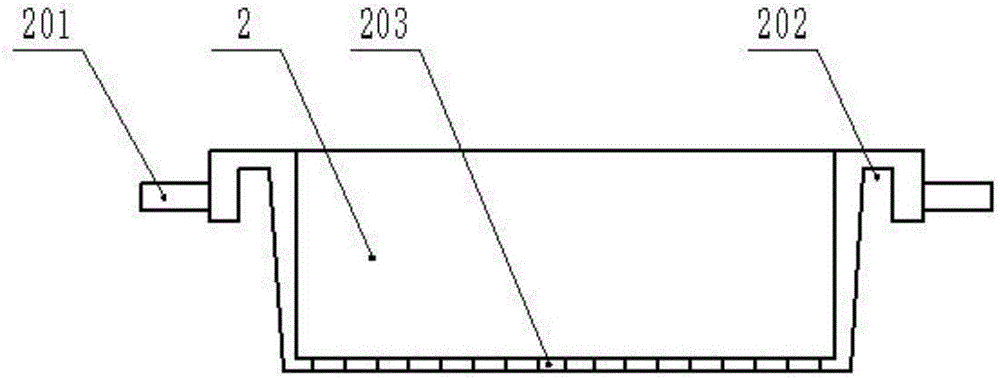

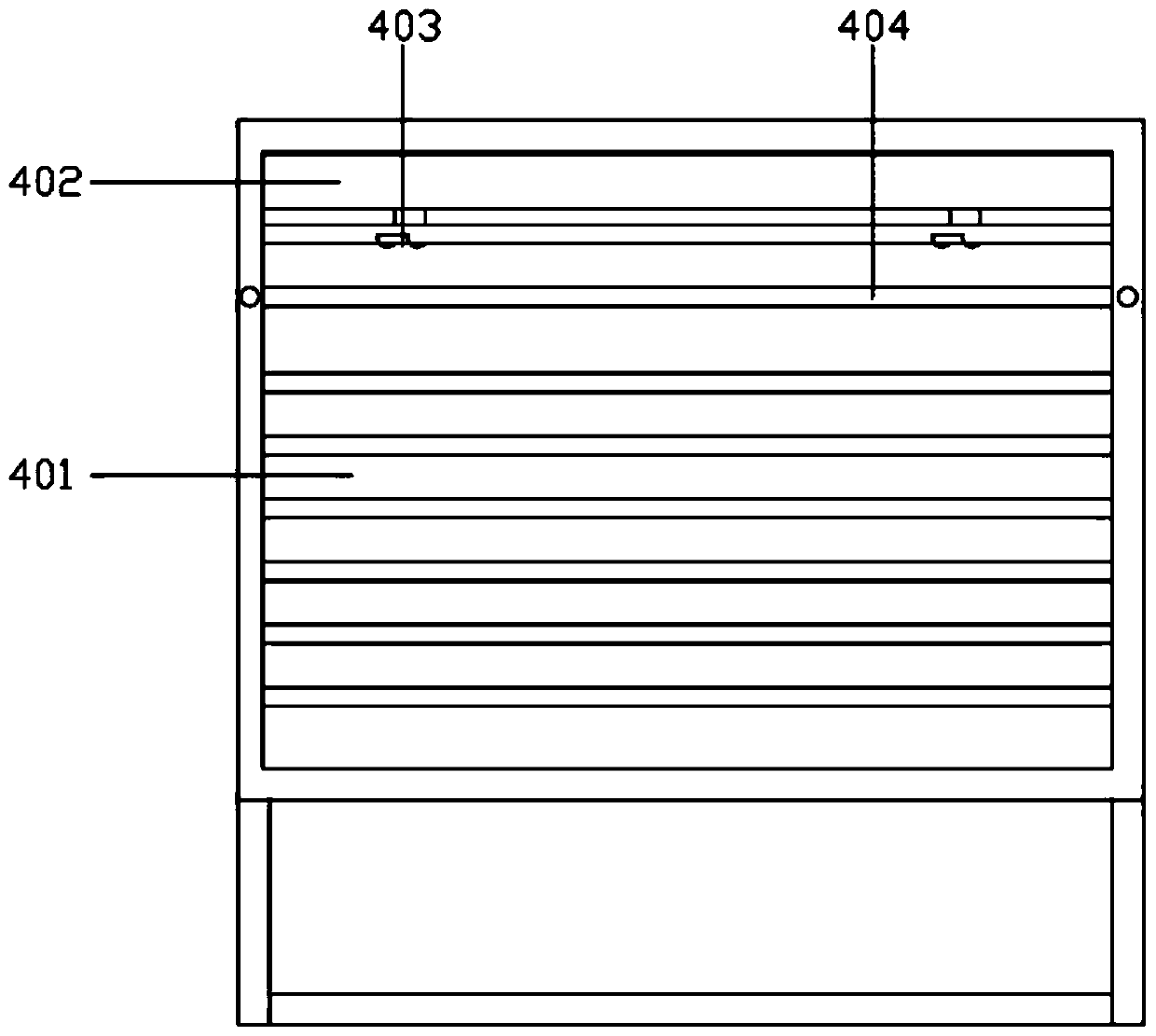

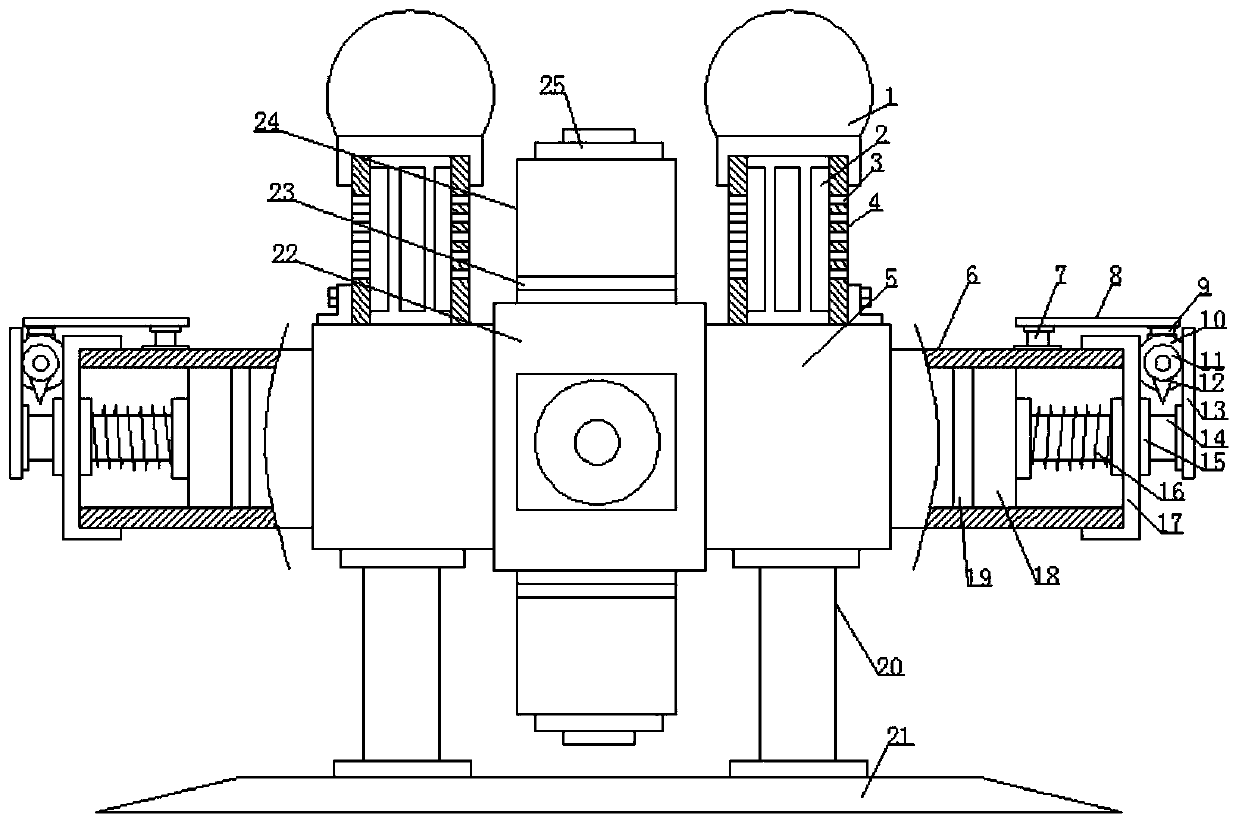

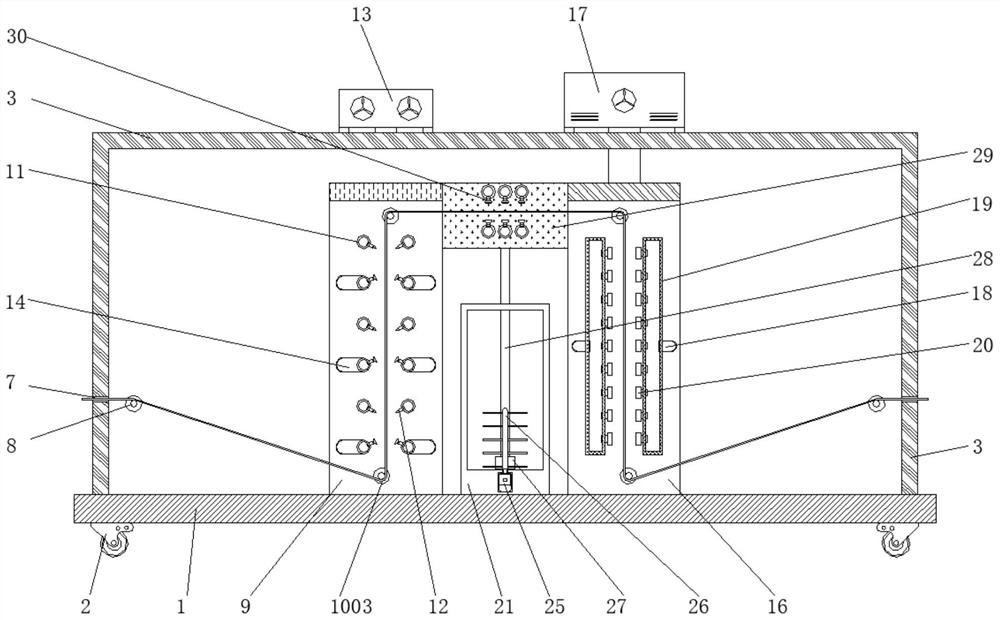

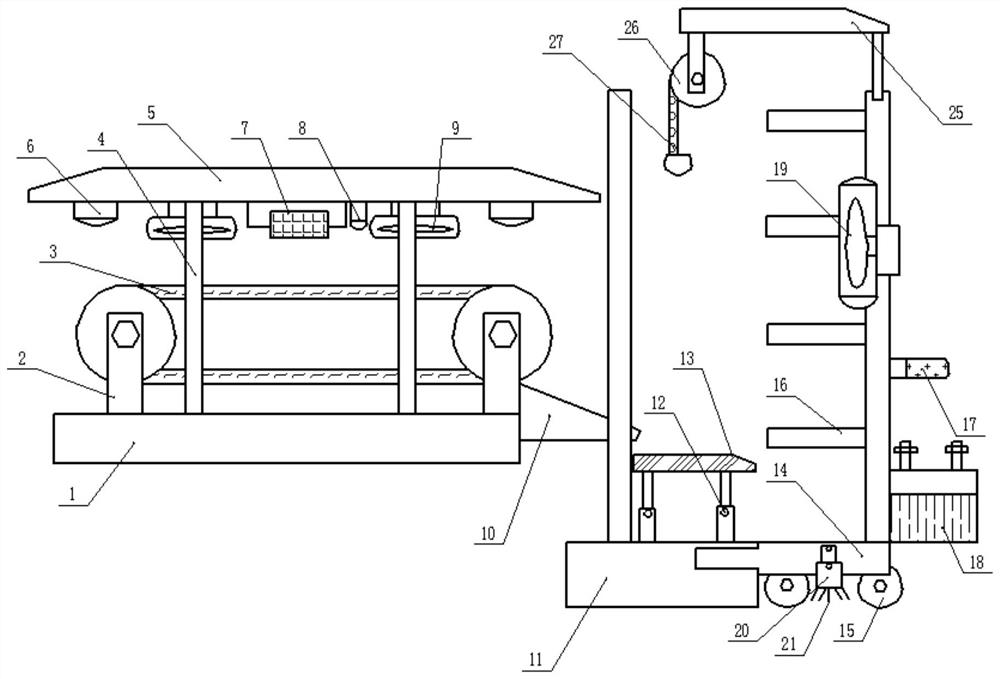

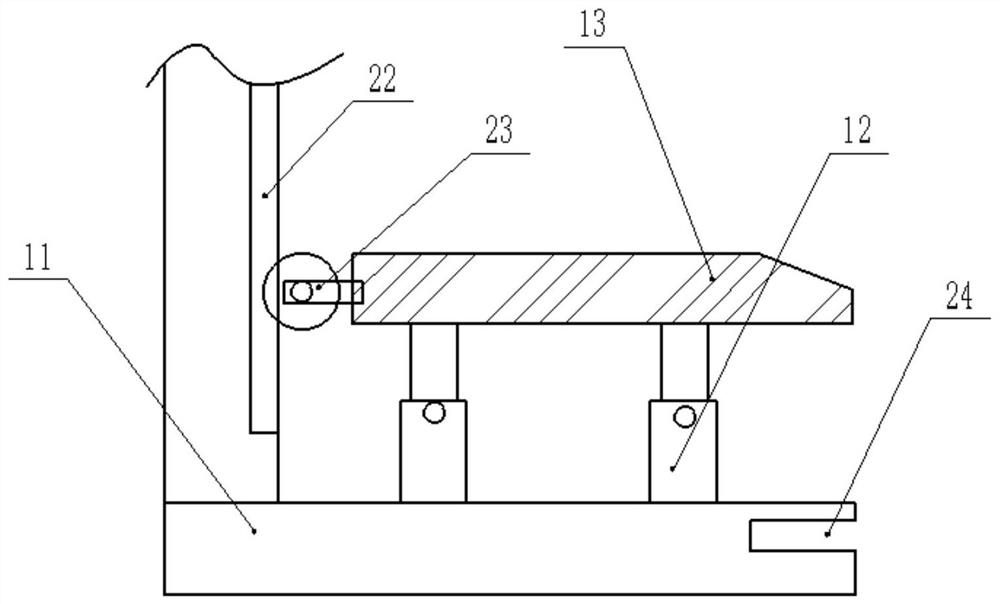

Air knife device of glass air knife cleaning machine

InactiveCN104117504AEasy to air dryStable deliveryDrying gas arrangementsCleaning using gasesEngineeringAir knife

The invention relates to an air knife device of a glass air knife cleaning machine. The air knife device comprises bases which are symmetrically arranged, and a conveying belt and an air knife are arranged between the two bases. The conveying belt is composed of a plurality of guide rollers which are arranged in parallel, and belt wheels are arranged at the ends of the guide rollers respectively. Each base consists of an upper base and a lower base. The air knife comprises an upper air knife and a lower air knife. The bases are both connected with a support by the aid of mounting blocks at the bottoms of the bases, the support comprises vertical racks and adjusting screw rods, and the vertical racks and the adjusting screw rods are arranged in parallel. A cross beam is horizontally arranged between each vertical rack and the corresponding adjusting screw rod, one end of each cross beam is placed in a sliding chute of the corresponding vertical rack and is fixedly connected with the corresponding vertical rack by the aid of a locking screw, and the other end of each cross beam is matched and spirally connected with the corresponding adjusting screw rod. The air knife is provided with an air inlet hole and an air outlet groove. According to the air knife device of the glass air knife cleaning machine, due to the guide roller conveying structure, conveying is stable and adjusting is easy; the support is arranged to adjust the position of the air knife, air drying treatment can be conducted on glass sheets of different thicknesses conveniently, drying of the same degree can be carried out on the upper surfaces and the lower surfaces of the glass sheets, adjusting operation is simple and convenient, and efficiency is high.

Owner:SUZHOU YIHE OPTICAL

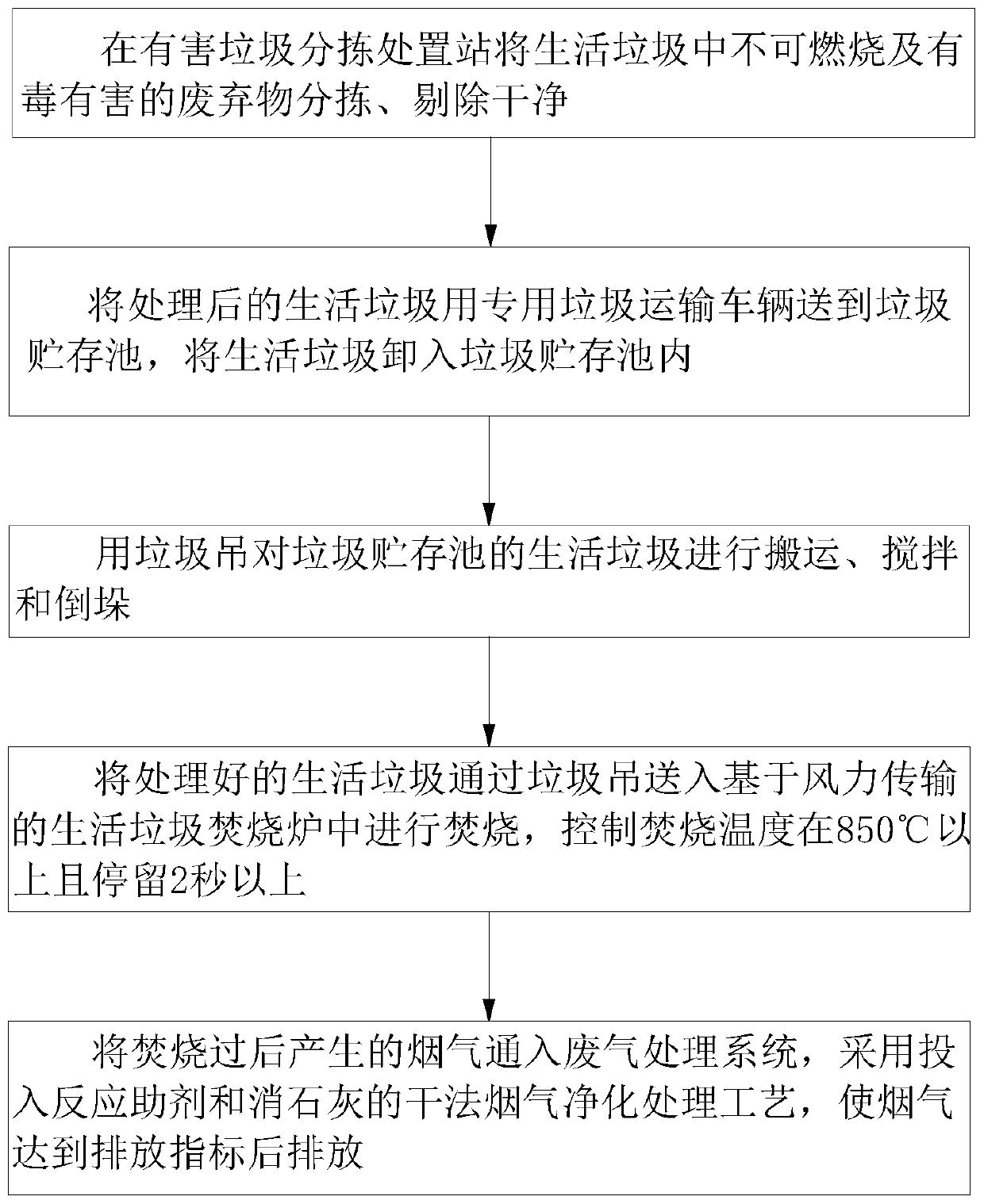

Domestic garbage incinerating technology

The invention relates to the technical field of a garbage treatment technology, in particular to a domestic garbage incinerating technology. The domestic garbage incinerating technology comprises thefollowing steps of sorting waste which cannot be combusted, toxic and harmful in domestic garbage in a harmful garbage sorting treatment station, and performing thorough removing; then transporting the treated domestic garbage to a garbage storing pond through a special garbage transporting vehicle; then performing carrying, stirring and stack transferring on the domestic garbage discharged into the garbage storing pond with a garbage crank; guaranteeing the situation that the components of the domestic garbage in an incinerator is uniform and the incineration efficiency is improved; and thentransporting the domestic garbage into the incinerator through the garbage crank for incineration, ventilating flue gas produced after incineration into a waste gas treating system, and after the fluegas achieves the discharging indexes, exhausting the flue gas. According to the domestic garbage incinerating technology disclosed by the invention, domestic garbage is pretreated, and then is pouredinto the incinerator to enable the domestic garbage to be sufficiently combusted; and the combusted flue gas is treated, and after reaching the standard, the flue gas is exhausted. The incinerator issimple in structure, convenient to use and high in incineration efficiency.

Owner:淮安方之形企业管理有限公司

Method for producing belite-gypsum material from roasted sludge and waste gypsum of furnace in fluid bed

The invention discloses a method for producing a belite-gypsum material from roasted sludge and waste gypsum of a furnace in fluid bed. The method comprises the following steps: (1) transforming high water-content sludge ridge grain seeds into modified sludge residues; (2) carrying out raw material compounding and homogenizing on the modified sludge residues obtained in the step (1) with waste gypsum, waste rock ballasts and a corrective material; (3) drying the raw material mixture obtained in the step (2) by virtue of hot exhaust air of the furnace in fluid bed, and carrying out flue gas desulfuration and sulfur fixation; (4) mixing the raw material mixture dried in the step (3) with a proper amount of fire coal, adding to the furnace in fluid bed and roasting into a clinker; and (5) grinding the clinker obtained in the step (4) to obtain powder, namely the belite-gypsum material, or taking the clinker obtained in the step (4) as the belite-gypsum material. The method is simple in process, low in control requirements, and low in grinding energy consumption and firing energy consumption; bulk waste residues such as sludge and industrial waste gypsum can be largely and widely dissolved; and the prepared belite-gypsum material is wide in application.

Owner:长沙紫宸科技开发有限公司

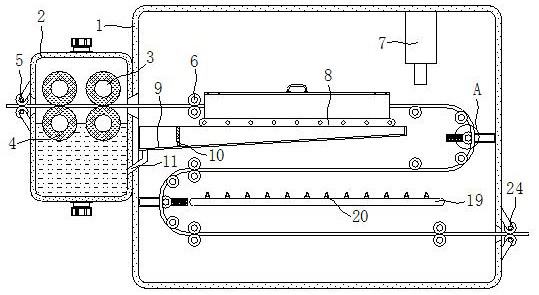

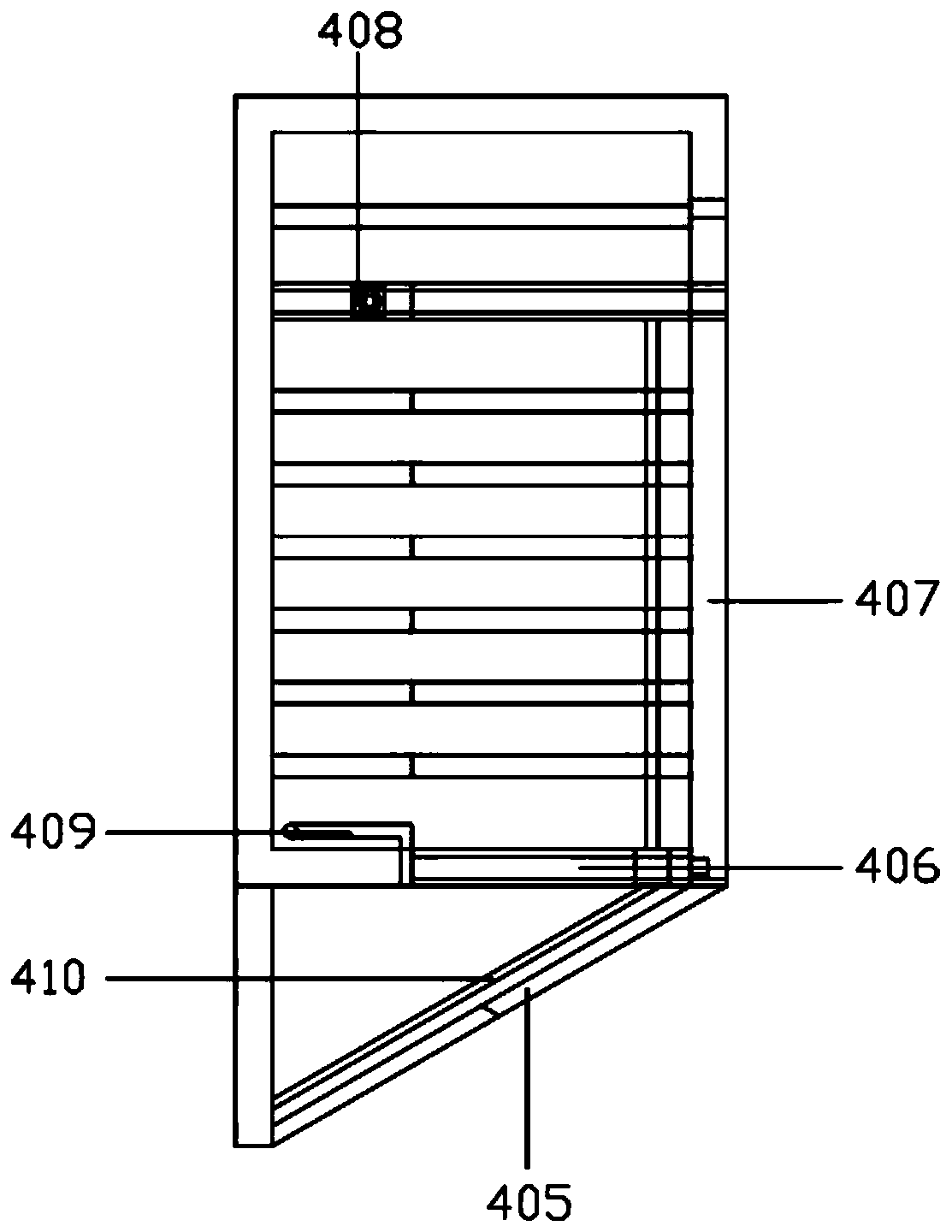

Wire insulating paint efficient-clearing device

InactiveCN109290270AHandle cleanImprove work efficiencyDrying gas arrangementsCleaning using toolsEngineering

The invention relates to the field of unmanned aerial vehicles, in particular to a wire insulating paint efficient-clearing device which comprises a box body, wherein a partition plate is arranged atthe upper end of the interior of the box body; a cleaning cavity is positioned on the lower side of the partition plate; a pay-off roll is mounted at the left end of the upper side of the partition plate; a take-up roll is mounted at the right end of the upper side of the partition plate; a groove is formed in the middle of the partition plate; a connecting hood is mounted inside the groove through a bolt; supporting rods are welded to the left and right ends of the upper side of the connecting hood; gear racks are arranged at the left and right ends of the interior of the connecting hood; a connecting plate is arranged at the upper end of the clearance between the gear racks; the left and right sides of the connecting plate are connected with gears through connecting shafts; a connectingpipe is welded to the lower side of the connecting plate; a brush is welded to the lower side of the connecting pipe and arranged at the lower end of the interior of the cleaning cavity; a baseplate is fixedly mounted at the bottom of the cleaning cavity and positioned below the brush; and limiting plates are arranged on the left and right sides of the baseplate. By the adoption of the wire insulating paint efficient-clearing device provided by the invention, the effective and convenient disposal of insulating paint on a wire can be achieved, thereby improving the working efficiency of the wire insulating paint efficient-clearing device and facilitating the use of the wire insulating paint efficient-clearing device.

Owner:FUJIAN NANAN XIAMEI ELECTRONICS EQUIP FACTORY

Dyeing device for textile processing

ActiveCN108411523AAvoid uneven dyeingImprove dyeing qualityLiquid/gas/vapor removal by squeezing rollersLiquid/gas/vapor removal by gas jetsEngineeringUltimate tensile strength

The invention discloses a dyeing device for textile processing. The device comprise a dyeing pool, a mounting table is arranged above the dyeing pool, the top of the mounting table is vertically provided with a first storage channel, the inner portion of the first storage channel is provided with four transfer rollers in parallel, the four transfer rollers are distributed in trapezoid, the four transfer rollers are provided with a conveyor belt, connecting blocks are fixed on the outer wall of the conveyor belt, the sides, away from the conveyor belt, of the connecting blocks are rotationallyconnected with fixing plates, a first mounting plate is fixed at one end of the top of the mounting table, a linear actuator arranged aslant is fixed on the first mounting plate, a connecting plate located in the first storage channel is fixed at an output end of the linear actuator, and the two ends of the side wall, close to the conveyor belt, of the connecting plate are both rotationally connected with rotating plates. The dyeing device for the textile processing has the advantages that the occurrence of uneven dyeing of the textile caused by winding and curling during dyeing is avoided, the dyeing quality of the textile is improved, the labor intensity of workers is reduced, and the use needs of people are met.

Owner:HAINING WARP KNITTING IND ZONE HUAWEI TEXTILE

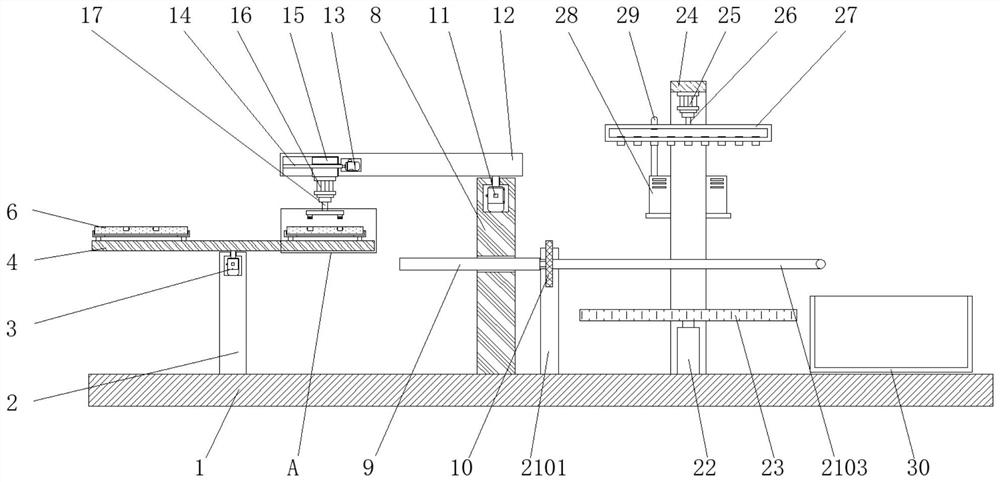

Both-side printing equipment for medical paper-plastic bag production

ActiveCN111409357AEasy to operateSimple structureRotary pressesPrinting press partsEngineeringPlastic bag

The invention discloses both-side printing equipment for medical paper-plastic bag production, and relates to the technical field of medical paper-plastic bags. The equipment comprises a base. The twosides of the upper end of the base are symmetrically provided with two side plates. A baffle is arranged at the portions, below the front portion of an unreeling roller, of the inner sides of the side plates. A first sweeping plate is arranged at the portion, at the front side of the baffle, of the inner sides of the side plates. A first guiding roller is arranged below the front sides of the first sweeping plate. A first auxiliary plate is arranged over the first guiding roller. Surface treatment is performed on the two side faces of a paper-plastic bag through the sweeping plate before printing, air-drying treatment is performed at the printed position by means of a cooling mechanism, meanwhile, by cooperatively using the adjustable auxiliary plate and a printing roller, the position ofthe auxiliary plate can be conveniently adjusted, and therefore the problem that when the paper-plastic bag and the printing roller are in contact printing, printing is not clear enough due to the influence of stretchable tension of the paper-plastic bag is avoided. The both-side printing quality of the paper-plastic bag is improved, and the both-side printing speed of the paper-plastic bag is increased.

Owner:安徽宜人医用包装有限公司

Automatic osmanthus tree bark cutting and collecting equipment

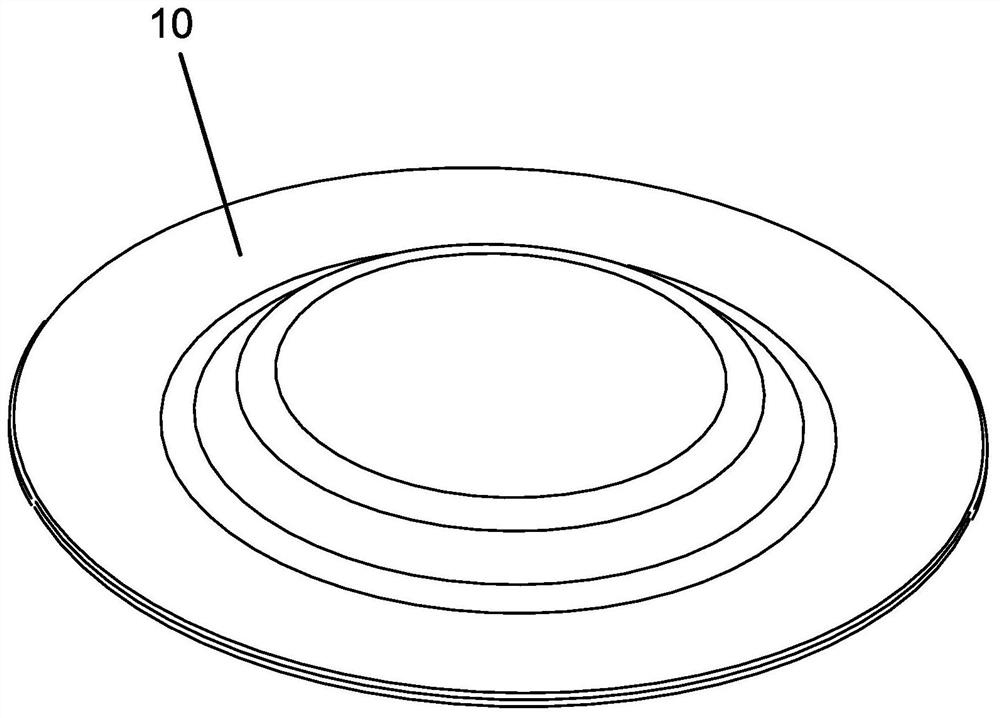

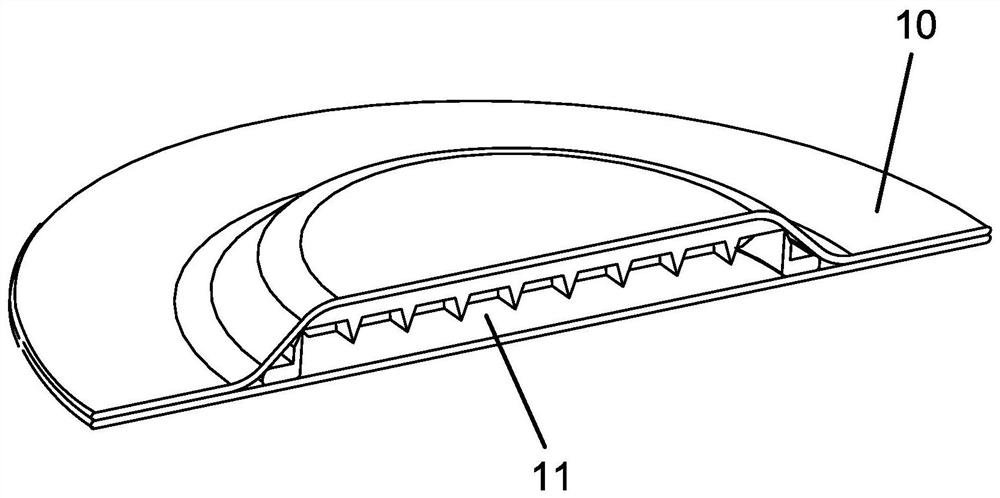

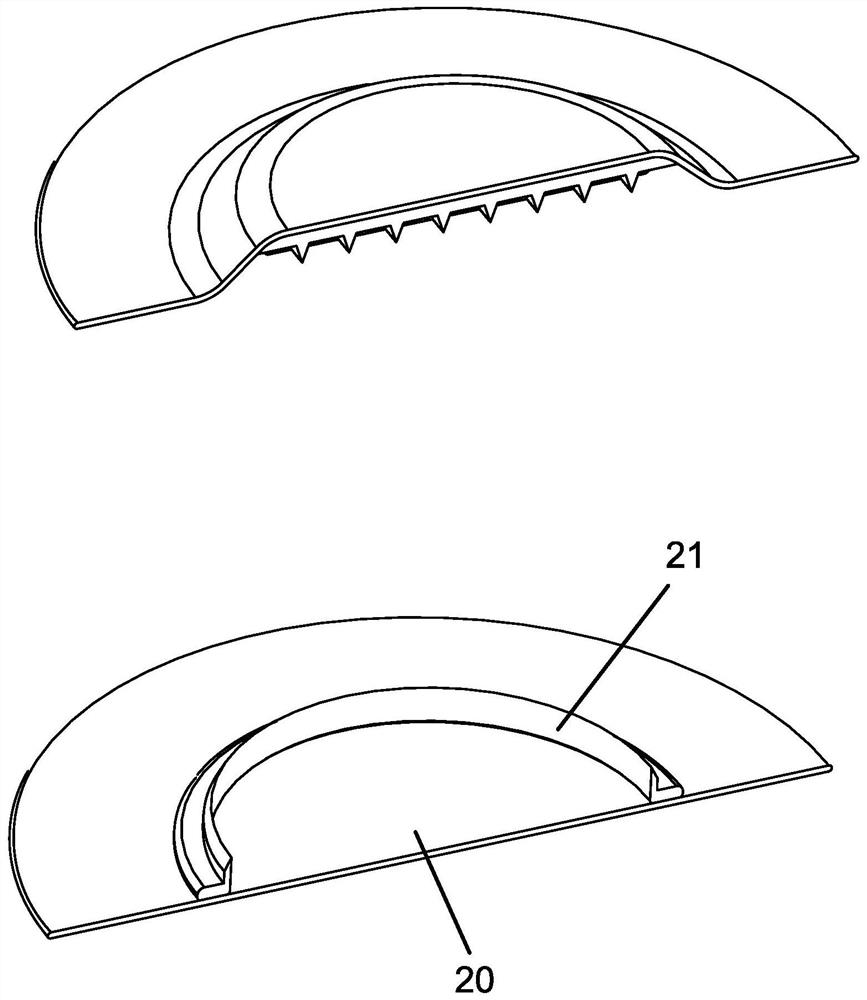

InactiveCN112166807ACutting depth and radian neatAppropriate depthHarvestersHorticultureElectric machinery

The invention discloses automatic osmanthus tree bark cutting and collecting equipment. The equipment comprises a shell, wherein reciprocating cavities which are vertically symmetrical are formed in the left side of the shell, reciprocating motors are arranged on the left side walls of the reciprocating cavities, reciprocating motor shafts are rotatably arranged on the right sides of the reciprocating motors, left half gears are fixedly arranged on the left sides of the reciprocating motor shafts, right half gears are fixedly arranged on the right sides of the reciprocating motor shafts, and reciprocating shafts are rotatably arranged on the upper side walls of the reciprocating cavities. The automatic osmanthus tree bark cutting and collecting equipment can adapt to the diameter of an osmanthus tree, compared with a traditional cinnamon collecting method, the automatic osmanthus tree bark cutting and collecting equipment is more convenient and faster, does not need to be operated by people, and is neater in cutting depth and radian, the obtained cinnamon is more complete and attractive, natural growth of the cut osmanthus tree can be effectively prevented from being affected, thecut cinnamon is proper in depth, excessive waste and damage to the osmanthus tree are avoided, and operation of subsequent processes such as air-drying and sun-curing of the cinnamon is facilitated.

Owner:DONGYANG BOTONG CHINESE MEDICINE TECH CO LTD

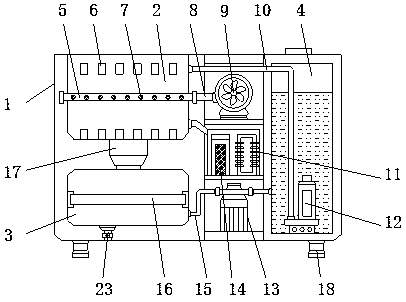

Automatic cleaning device for quartz wafers

InactiveCN110479696AAchieve circular flowAchieve reflowDrying gas arrangementsCleaning using liquidsAir blowerCirculating pump

The invention discloses an automatic cleaning device for quartz wafers. The automatic cleaning device comprises a shell, wherein the bottom of the cleaning tank is connected with a filtering tank through a drainage pipeline, a filter screen plate is arranged in a filter tank, limiting blocks are symmetrically arranged on the side wall inside the cleaning tank, a first pipeline is arranged inside amounting groove, spray heads are uniformly arranged on the surface of the first pipeline at equal intervals, an air blower is installed inside the shell, the output end of the blower is connected with the first pipeline through a second pipeline, a circulating pump is installed inside the shell, a water pump is installed inside the water tank, an ultrasonic generator is connected with an ultrasonic transducer, and the output end of the ultrasonic transducer is connected with one side of the cleaning tank. According to the automatic cleaning device, by arranging the first pipeline, the limiting blocks, the spray heads, the second pipeline, the air blower, the water pump, the circulating pump and the filter screen plate structure, the problems of no air drying function and low cleaning efficiency of existing equipment are solved.

Owner:马鞍山荣泰科技有限公司

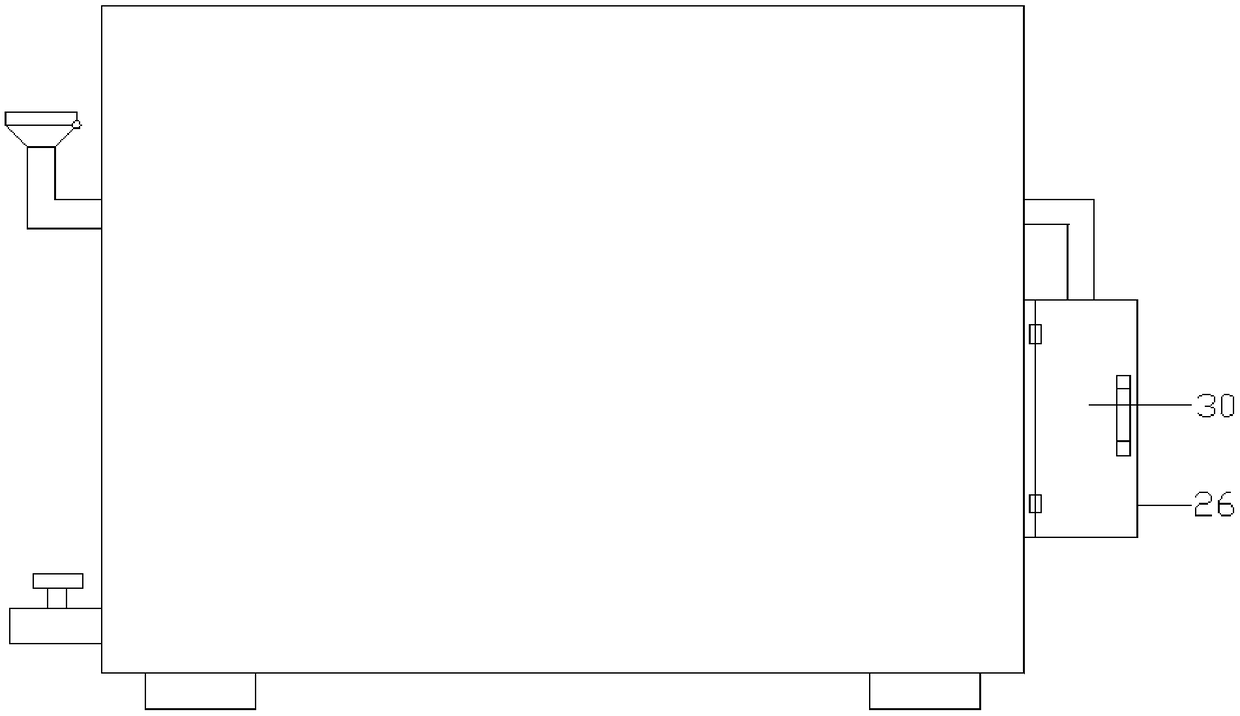

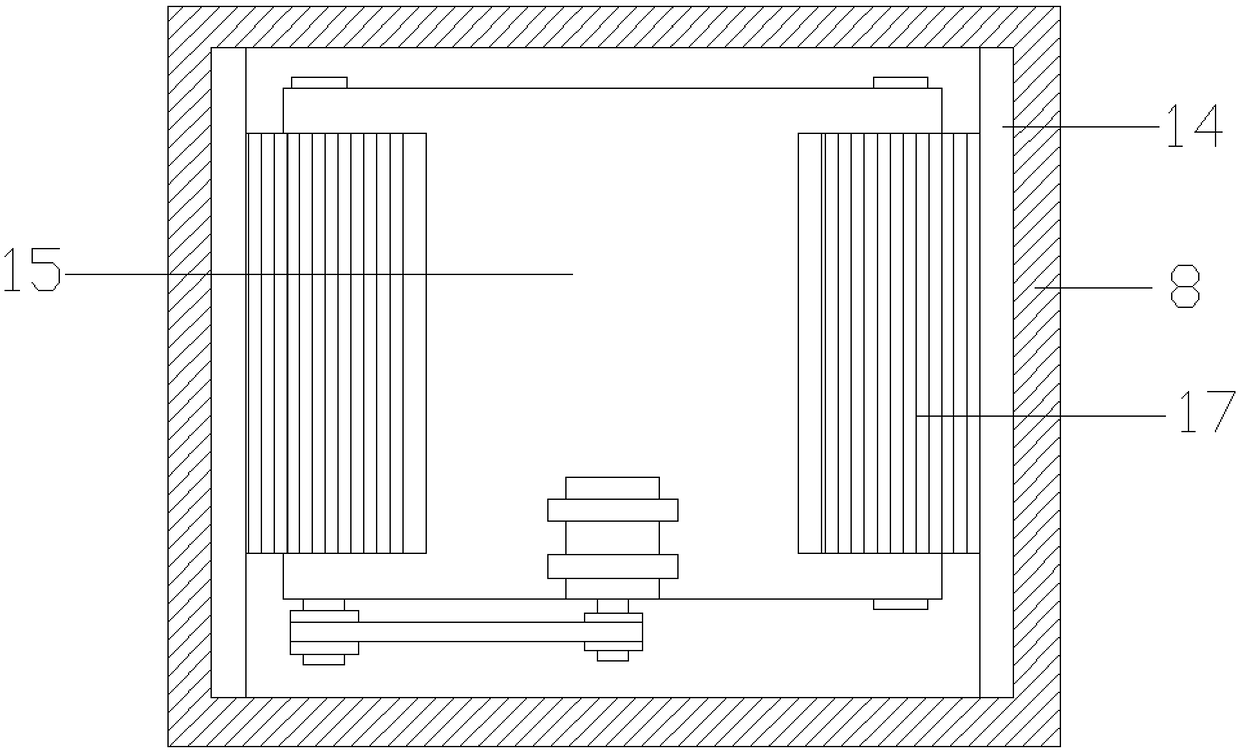

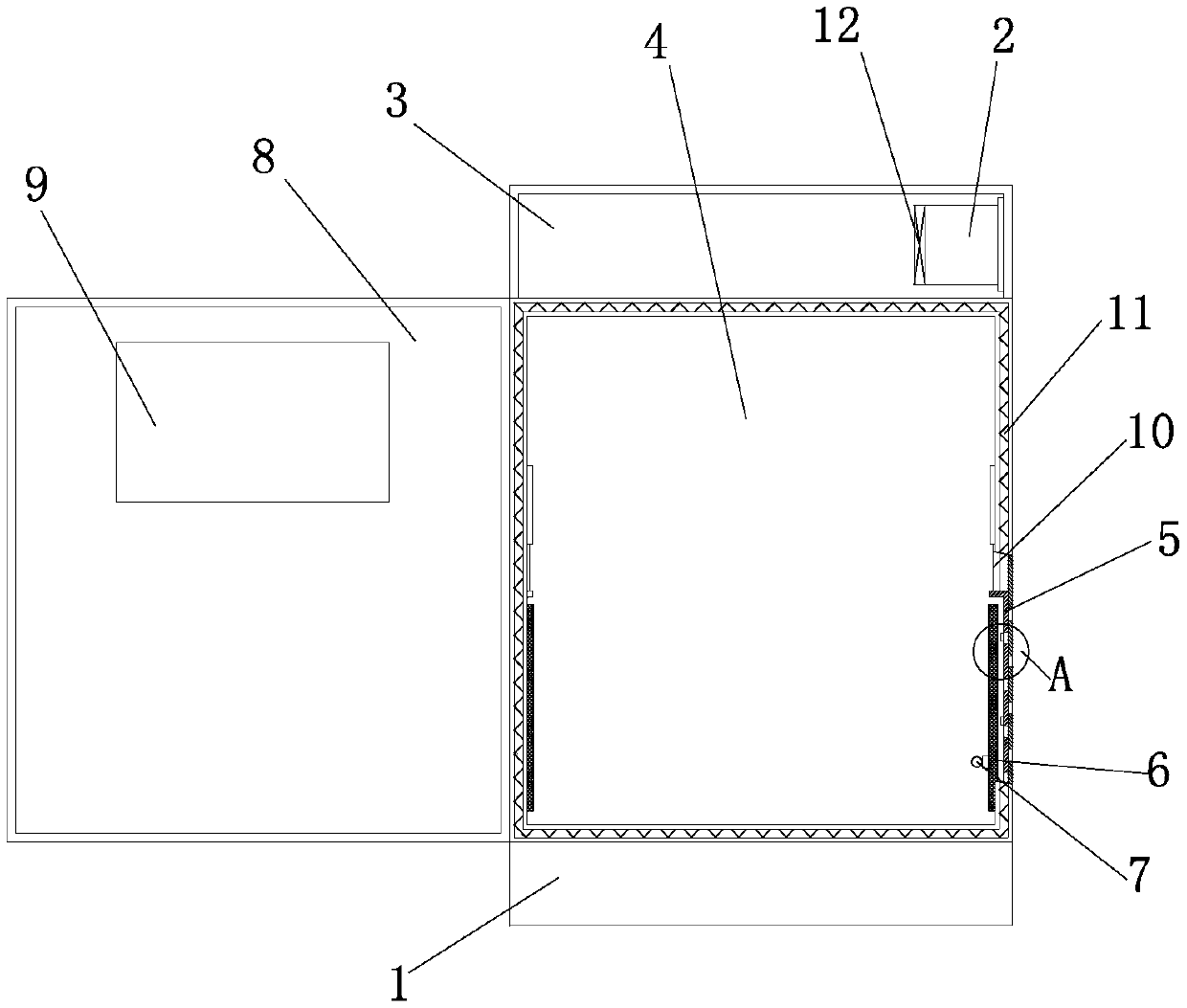

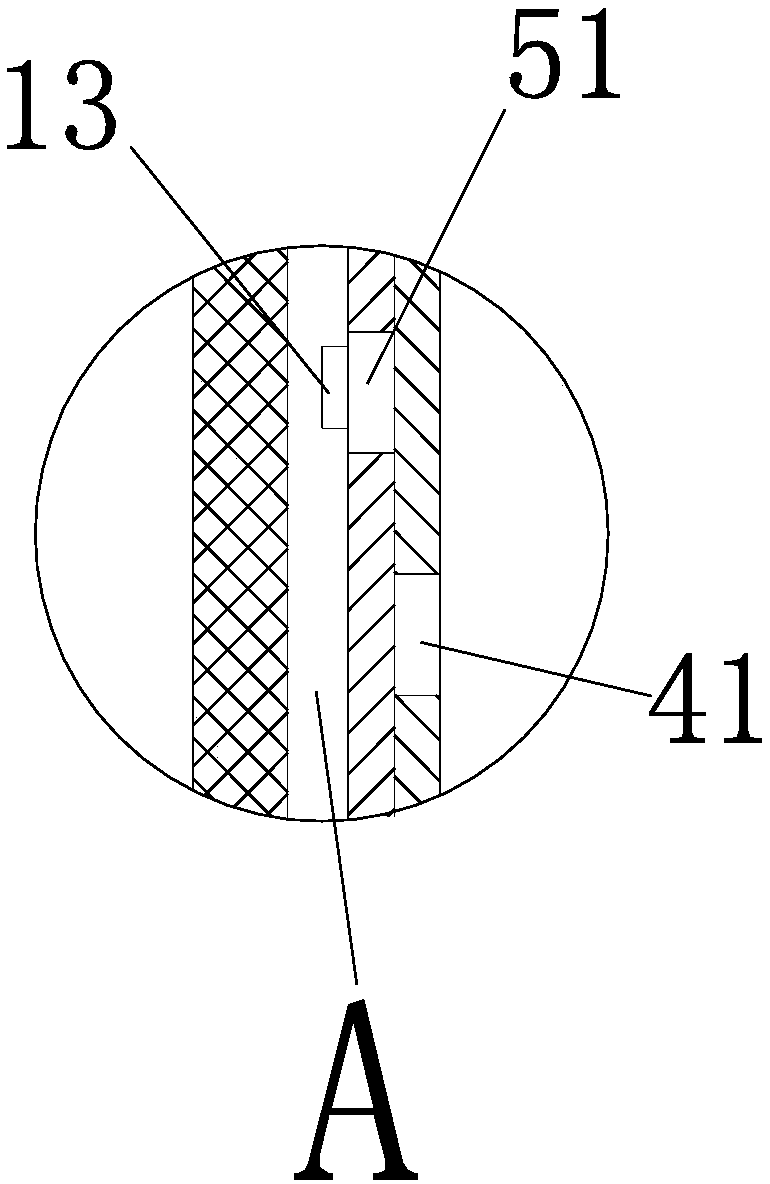

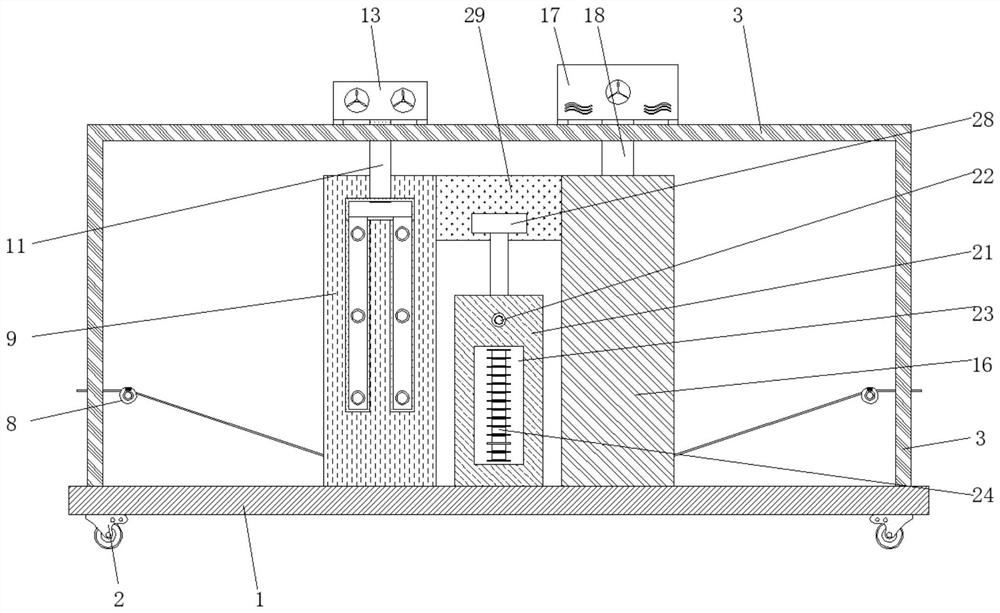

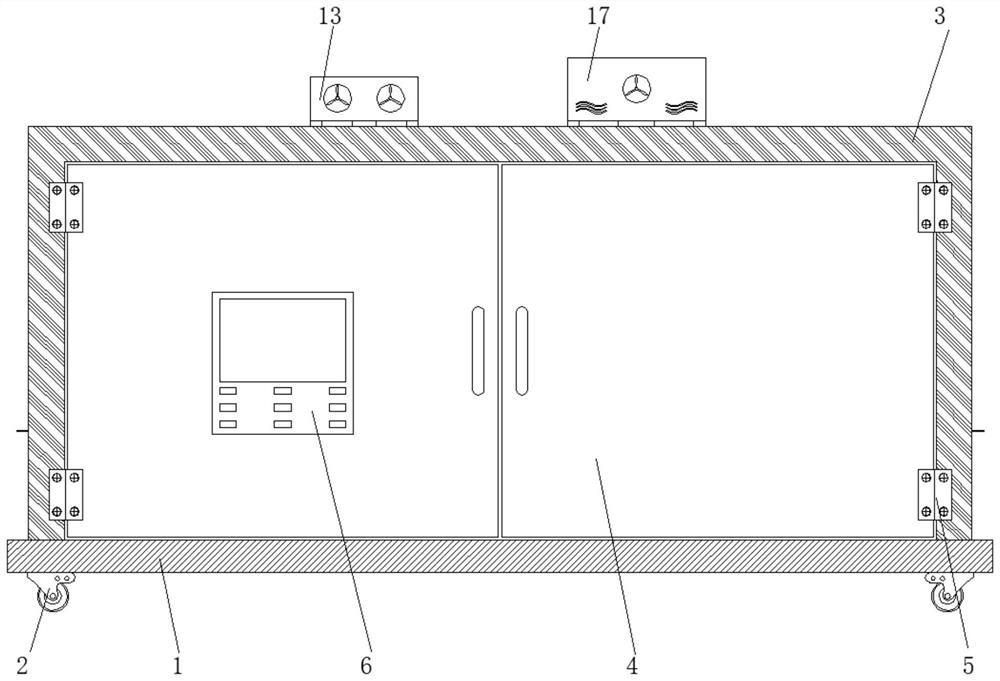

Power distribution control cabinet

InactiveCN111276887AAvoid enteringEasy to air drySubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsDistribution controlMoisture absorption

The invention discloses a power distribution control cabinet. The cabinet comprises a cabinet body, an exhaust cavity and an equipment cavity are arranged in the cabinet body from top to bottom. A through hole communicated with the exhaust cavity is formed in the top of the left side of the equipment cavity; a plurality of first air inlets are formed in the left side and the right side of the lower portion of the equipment cavity, baffles are slidably arranged on the inner sides of the first air inlets, a moisture absorption layer is arranged in the equipment cavity on the inner sides of the baffles, a temperature and humidity sensor is arranged on the moisture absorption layer, a cabinet door is arranged on the left side of the cabinet body in an openable and closable mode, and a controlpanel is arranged on the cabinet door. The moisture absorption layer is arranged near the air inlets, so it is convenient to dry inlet air and moisture is prevented from entering the equipment cavity;parameters of the equipment cavity are controlled through a temperature and humidity sensor, signals are transmitted to thecontrol panel when the temperature is high, through a movable baffle, an airinlet channel is opened, an electric air door is opened, a draught fan is started, heat is discharged out of the cabinet body, and when the humidity of themoisture absorption layer is high, the signals are transmitted to the control panel to remind a user to replace moisture absorption materials.

Owner:重庆豪宏涞电气有限公司

Efficient dedusting, cooling and air-drying integrated equipment for cable processing

ActiveCN112216442APlay the role of limit supportAchieve dust removal effectCleaning using gasesCable/conductor manufactureWater storageWater storage tank

The invention discloses an efficient dedusting, cooling and air-drying integrated equipment for cable processing. The equipment comprises a dedusting mechanism, a primary cooling mechanism, a water storage tank and a limiting frame, a second bearing plate is arranged on the right side of a first bearing plate, the primary cooling mechanism penetrates through the top of a bearing table, and the water storage tank is fixed to the top of the bearing table in a penetrating mode. A second fixed pulley is arranged on the upper side of the water storage tank, a third fixed pulley is rotatably connected into the water storage tank, a third bearing plate is arranged on the right side of the water storage tank, a fourth fixed pulley is rotatably connected between the third bearing plate, and a fan is arranged on the right side between the fixing sleeve and the limiting frame. And the torsion mechanism is arranged on the limiting frame. According to the efficient dedusting, cooling and air-dryingintegrated equipment for cable processing, water needs to be introduced into the water storage tank before the equipment is used, in the process that a cable is wound around the third fixed pulley, water in the water storage tank can conduct secondary cooling treatment on the cable, and the cooling effect is conveniently enhanced.

Owner:镇江市沃通机械有限公司

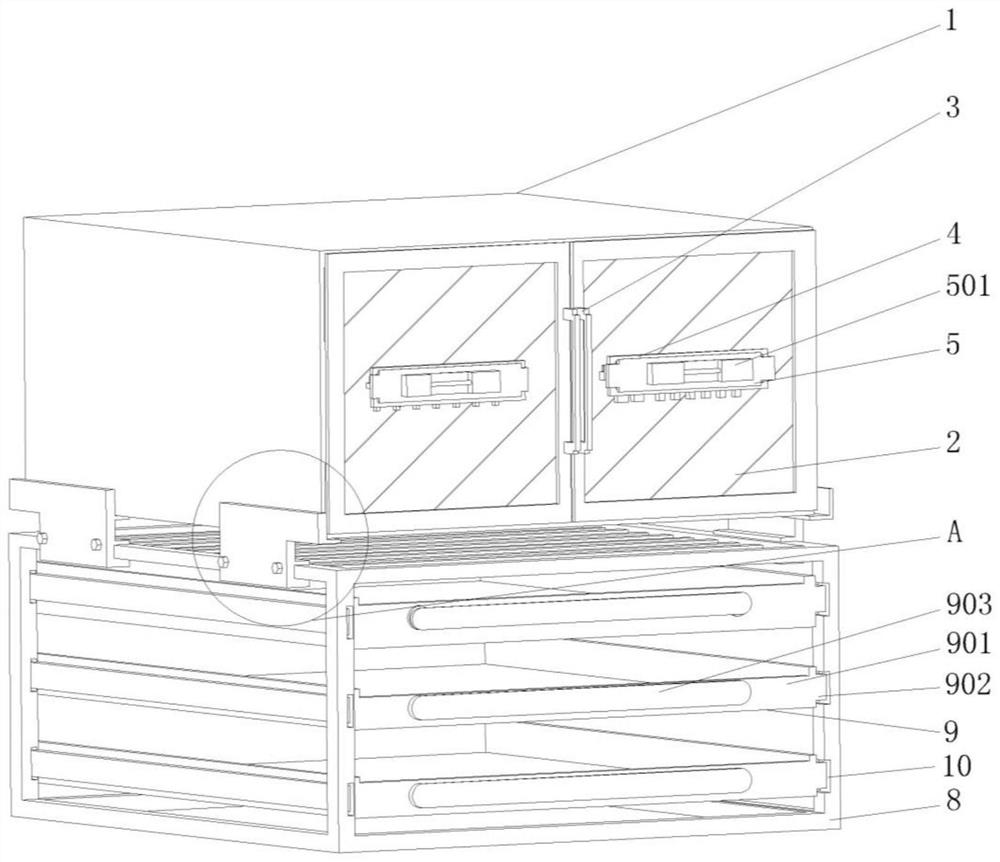

Double-opening type sauce brushing bread baking system

ActiveCN114041476AEffective brush materialQuick installationFood processingBaked articles handlingWindow openingEngineering

The invention discloses a double-open type sauce brushing bread baking system which comprises a baking machine, a glass door is installed at the front end of the baking machine, handles are arranged on the two sides of the glass door, a window opening frame is installed in the middle of the glass door, a sauce brushing mechanism is installed in the middle of the window opening frame, and an installation mechanism is installed in the middle of the sauce brushing mechanism. Fixing mechanisms are installed at the four corners of the baking machine, a bottom frame is installed at the bottom ends of the fixing mechanisms, a storage assembly is installed in the middle of the bottom frame, and sliding groove frames are arranged on the two sides of the bottom frame. According to the double-open type sauce brushing bread baking system, a series of structures are arranged, in the actual use process, a push rod of a hydraulic oil cylinder drives a feeding plate and a feeding box to move, the lower end of the feeding box is connected with a guide pipe, sauce in the feeding box is drained to a flowing box through the guide pipe and finally flows into a sauce brush, and the sauce brushing effect is improved. And the push rod of the hydraulic oil cylinder drives the sauce brush to move back and forth, so that bread in the baking machine can be effectively brushed.

Owner:东莞市利明轩食品有限公司

Payment barrier gate for intelligent parking lot

InactiveCN113585124AGuaranteed weightEasy to air dryTicket-issuing apparatusLighting elementsDriver/operatorEngineering

The invention discloses a payment barrier gate for an intelligent parking lot. The payment barrier gate comprises a base, a first supporting sleeve, a third supporting sleeve, a supporting plate, an electric drainage valve and an air drying mechanism; a cushion supporting plate is fixed to the front side of the right side of the upper end face of the base through first fixing bolts, and second supporting frames are fixed to the left side and the right side of the upper end face of the base correspondingly; a bearing frame is fixed between the top of the first supporting frame and the top of the second supporting frame, the supporting plates are fixed to the front side and the rear side of the upper end face of the base, the electric drainage valve penetrates through the right end face of the base and communicates with the water storage groove, and the air drying mechanism is fixed to the rear side of the right side of the upper end face of the base. According to the payment barrier gate for the intelligent parking lot, after a driver completes code scanning operation, a gate rod on the front side of the first supporting frame automatically rotates and is opened, and after a vehicle runs to a draining net plate, an air spraying head blows air to the vehicle, air drying treatment on the vehicle is facilitated, and the phenomenon that water is accumulated in the parking lot due to excessive water on the surface of the vehicle is avoided.

Owner:江苏火星科技有限公司

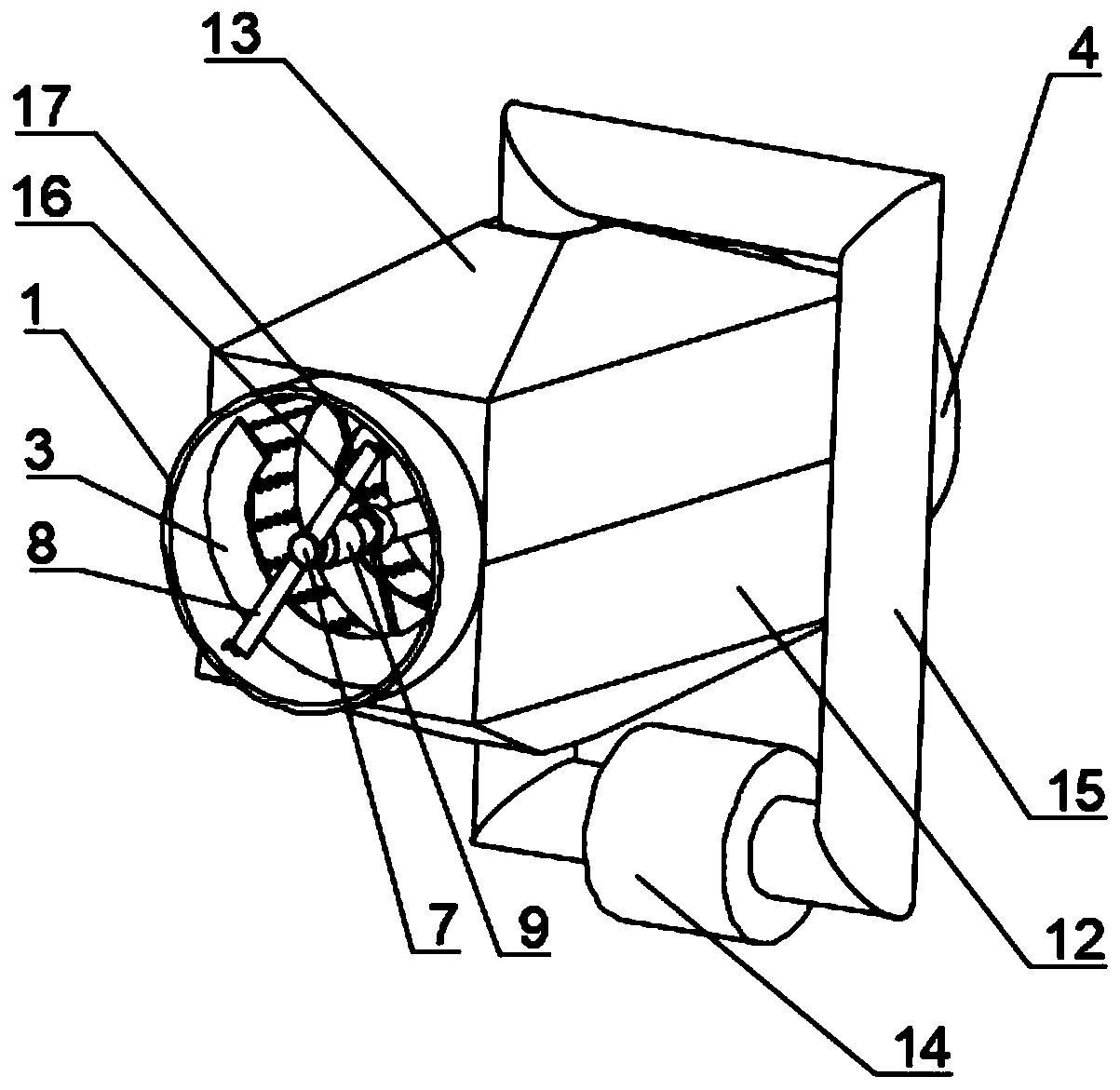

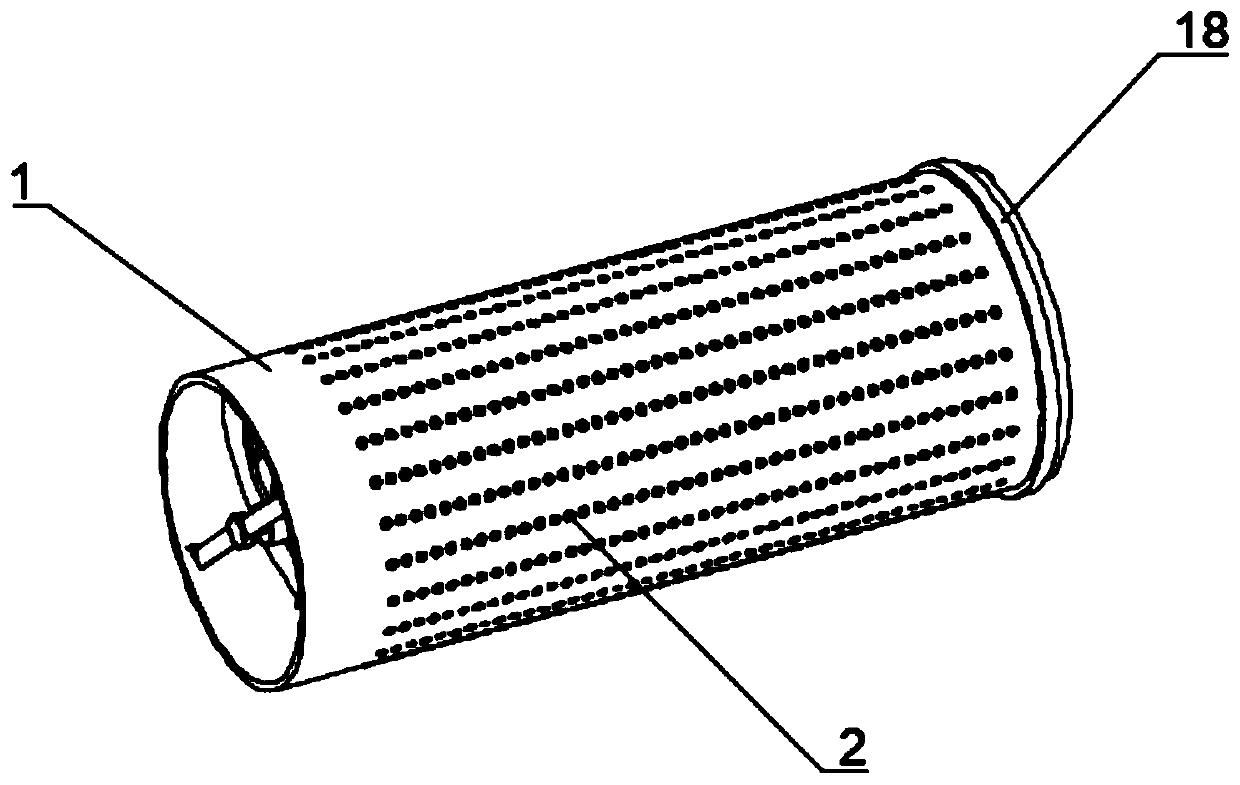

Slicing air dryer

PendingCN110186260AReduces the risk of sticking to the cutterEasy to air dryDrying gas arrangementsDrying solid materialsSpiral bladePulp and paper industry

The invention belongs to the technical field of food processing, and particularly relates to a slicing air dryer capable of reducing the possibility that dried bean curds adhere to a cutter when the dried bean curds are sliced and directly carrying out air drying treatment on the sliced dried bean curds. The device comprises an air drying roller, ventilation small holes are formed in the outer wall of the air drying roller, and an air supply hopper for supplying air to the ventilation small holes is arranged below the air drying roller; a spiral blade is fixed on the inner wall of the air drying roller, the discharge end of the air drying roller is provided with a discharge guide cylinder, the feeding end of the air drying roller is provided with a slicing structure for the dried bean curds, and the slicing structure for the dried bean curds is located in the air drying roller. The risk that the dried bean curd slices adhere to the cutter can be reduced, the dried bean curds is conveniently subjected to air drying treatment, and the processing time is shortened.

Owner:HEZE UNIV

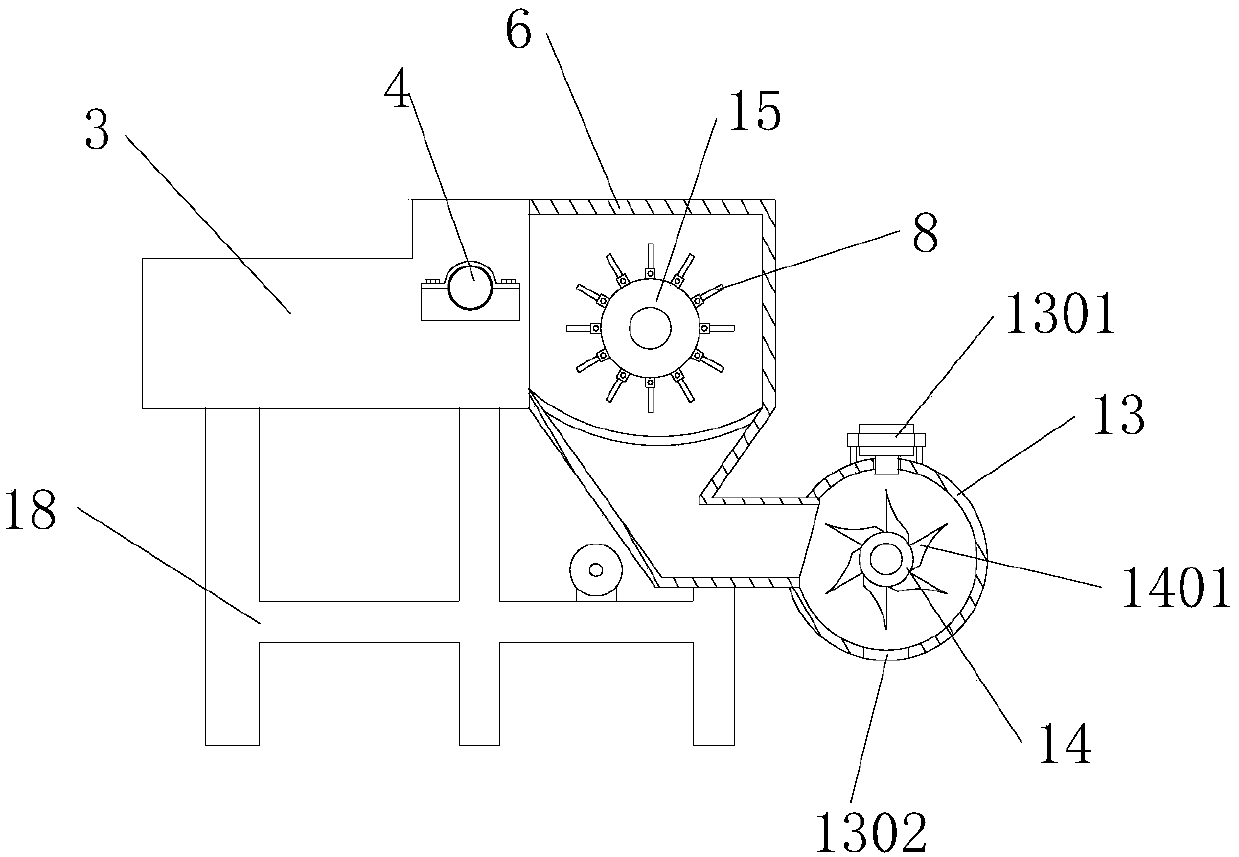

Edible mushroom waste treatment device

InactiveCN109603978AEasy to separateEasy to air dryDrying gas arrangementsDrying machines with non-progressive movementsEdible mushroomAir blower

The invention discloses an edible mushroom waste treatment device. The edible mushroom waste treatment device comprises a fixing plate, a first electric push rod, a discharging frame, a strip groove,a second electric push rod, a fixing seat, a crushing box, a first pulley, rotating blocks, a screen board, a first bearing, a second pulley, a second bearing, an air drying box, a hot air blower, a discharging port, a second rotating roller, rotating pieces, a first rotating roller, threaded holes, bolts and a bracket. The edible mushroom waste treatment device has the advantages of high functionality, convenient use, and stable operation; the waste and plastic bags are separated conveniently and quickly, the edible mushroom waste treatment device is beneficial to the rapid pulverization of the waste, the pulverization effect is good, the pulverized waste is air-dried conveniently, and the operation time of ground drying is shortened; and the waste can be recycled advantageously and preserved and used as feed, and the situation that the waste placed everywhere results in mycete generated to pollute the environment is avoided.

Owner:闽清县振兴农业专业合作社

Garment processing printing equipment with flattening function

PendingCN113858787APlay a role in taking overEasy to collectRotary pressesOther printing apparatusHydraulic cylinderEngineering

The invention discloses garment processing printing equipment with a flattening function. The garment processing printing equipment comprises a base, a second motor, a rotating frame, a flattening mechanism, an electric telescopic column, a bearing frame and a collecting box, a second support is fixed to the middle of the upper end face of the base, the rotating frame is rotationally connected to the top of the second support, and a first hydraulic cylinder is fixed to the bottom of a sliding block; and the flattening mechanism comprises a third support, a third electric telescopic rod and pull supporting rods, the third support is fixed to the base, the inner side of the third support is connected with the pull supporting rods through the third electric telescopic rod, and the electric telescopic column and the bearing frame are fixed to the other side of the upper end face of the base. A second hydraulic cylinder is fixed to the inner top of the bearing frame, and an air heater is fixed to the rear side of the bearing frame. According to the garment processing printing equipment with the flattening function, after the outer sides of the pull supporting rods are sleeved with clothes, the two pull supporting rods are far away from each other, so that the clothes are conveniently pulled, supported and flattened, and the clothes are smoother.

Owner:建湖县利达制衣有限公司

Self-cleaning type surface code spraying device for wires and cables for integrated circuits

InactiveCN114536997AEasy to tightenConvenient self-cleaning functionTypewritersOther printing apparatusStructural engineeringPrinting ink

The invention discloses a skin code spraying device for wires and cables for a self-cleaning integrated circuit, and relates to the technical field of wire and cable code spraying. The self-cleaning type surface code spraying device for the electric wire and the cable for the integrated circuit comprises a box body, a shell, a self-cleaning assembly, a blow-drying and collecting mechanism and a printing ink drying mechanism, the shell is fixedly installed on one side of the box body, a code spraying head is arranged on the inner wall of the box body, and a transition wheel is rotationally installed in the box body. According to the self-cleaning type surface code spraying device for the electric wire and cable for the integrated circuit, washing type self-cleaning is conveniently carried out before traction code spraying of the electric wire and cable, compared with a scraping cleaning mode, the situation that the surface of the electric wire and cable is deformed is avoided, the rotation direction of the cleaning sponge is opposite to the traction direction during cleaning, the cleaning quality is remarkably improved, and the cleaning efficiency is improved. And ink on the surface of the electric wire and cable can be conveniently dried by hot air after the electric wire and cable are subjected to code spraying, and the phenomenon that code spraying data are scratched when the electric wire and cable are pulled after code spraying and drying treatment are not performed in time is avoided.

Owner:本信电子科技重庆有限公司

Cleaning device for nozzle system of flow cytometer and cleaning method

ActiveCN113926775AEasy to cleanTemperature flow rate controlHollow article cleaningDrying gas arrangementsTemperature controlThreaded pipe

The invention discloses a cleaning device for a nozzle system of a flow cytometer and a cleaning method. The cleaning device comprises a flow cytometer shell, a cleaning box and a sample tube, and the side wall of the sample tube is communicated with a threaded tube; a conveying pipe is arranged in the cleaning box, one end of the conveying pipe penetrates through the cleaning box to be connected with a mounting part, the mounting part is used for communicating the conveying pipe with the threaded pipe, a temperature control part and a flow detection part are arranged on the side wall of the conveying pipe, and a cleaning agent self-switching part and an air source part are arranged in the cleaning box; a cleaning agent circulating device is arranged on the side wall of the cleaning box and comprises a shunting part arranged at the liquid discharge end of the flow cytometer shell, a water quality detection part which is arranged on the outer wall of the cleaning box and is connected with the shunting part through a circulating pipe, and a circulating part which is arranged on the inner wall of the cleaning box and is used for circularly discharging liquid in the water quality detection part into the conveying pipe. According to the cleaning device and the cleaning method, the sample tube and the nozzle system of the flow cytometer can be conveniently cleaned together.

Owner:FIRST AFFILIATED HOSPITAL OF KUNMING MEDICAL UNIV

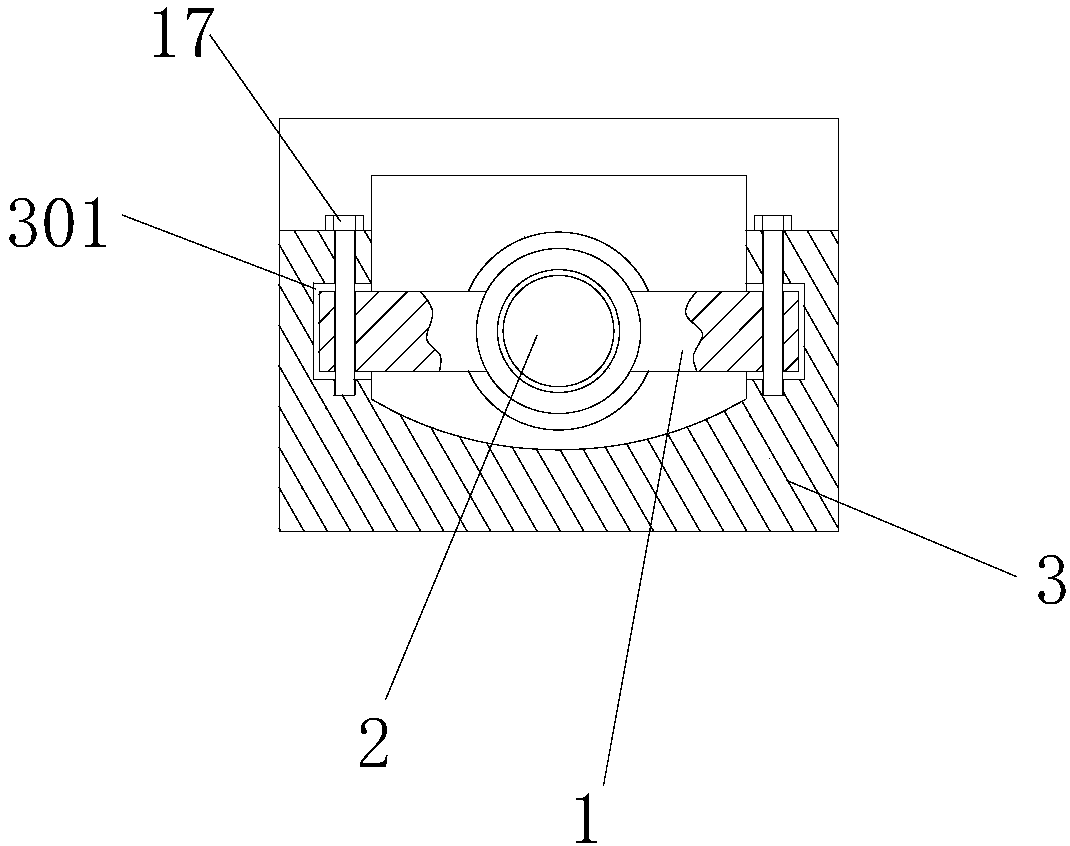

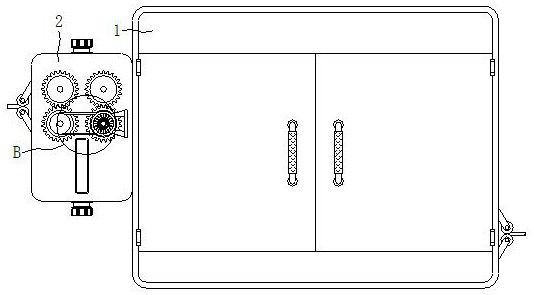

Simple duck egg cleaning machine

InactiveCN106000952AEasy to placeEasy to air dryTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentAnaerobic chamberReducer

The invention discloses a simple duck egg cleaning machine which comprises a cylinder body, a liner, a rotary base plate, a cross arm, a water pump, a water tank, a settling chamber, an anaerobic chamber, a first aerobic chamber, a second aerobic chamber, a sedimentation and drainage chamber and a flow valve. Supporting legs are arranged at the bottom of the cylinder body. The rotary base plate is arranged at the bottom end of the interior of the cylinder body. The lower end of the rotary base plate is connected with a central rotary shaft. The central rotary shaft penetrates through the cylinder body and extends downwards to be connected with a speed reducer. The speed reducer is connected with a motor. The motor is fixed to one supporting leg. A brush is arranged at the upper end of the rotary base plate. The liner is arranged above the brush. A fixing clamping groove is formed in the edge of the uppermost end of the liner. The fixing clamping groove is matched with the outer wall of the cylinder body. Handles are arranged on the outer side of the liner. A storage tank is arranged at the bottom of the liner. The bottom of the storage tank is hollowed out. The storage tank is located over the brush. The simple duck egg cleaning machine is simple in structure, convenient to use and clean, long in service life, capable of saving energy, environmentally friendly, good in cleaning effect and high in working efficiency, and the production cost is reduced.

Owner:SUQIAN HUAIHAI TECH SERVICES

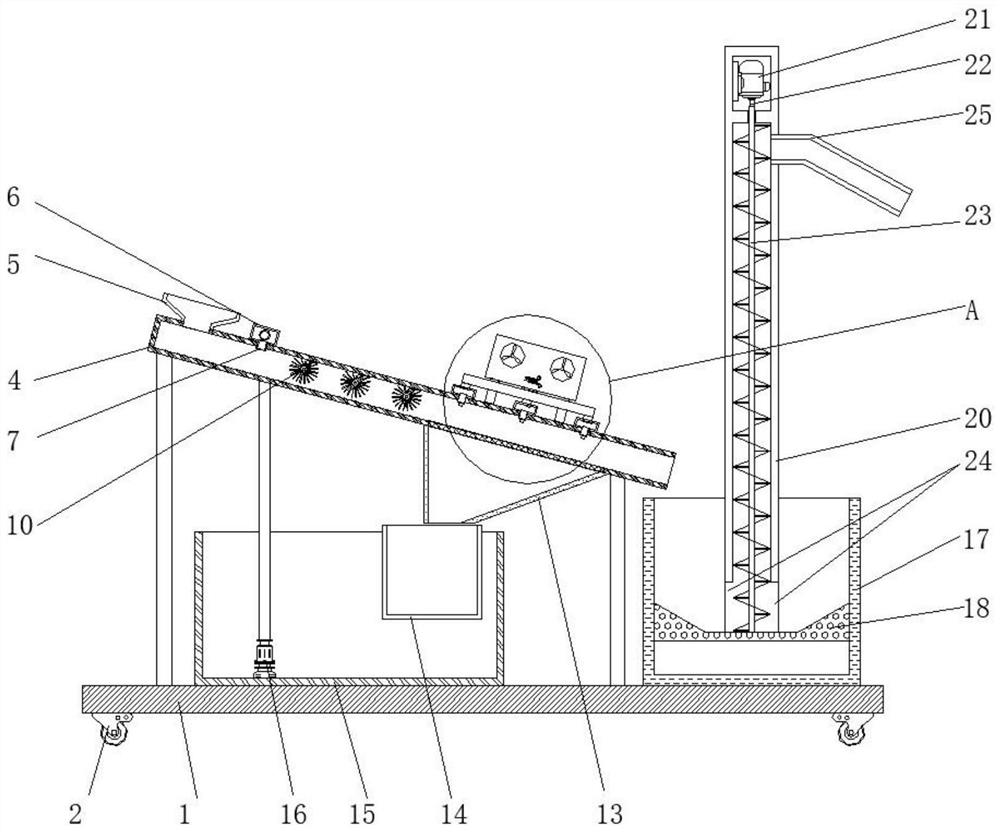

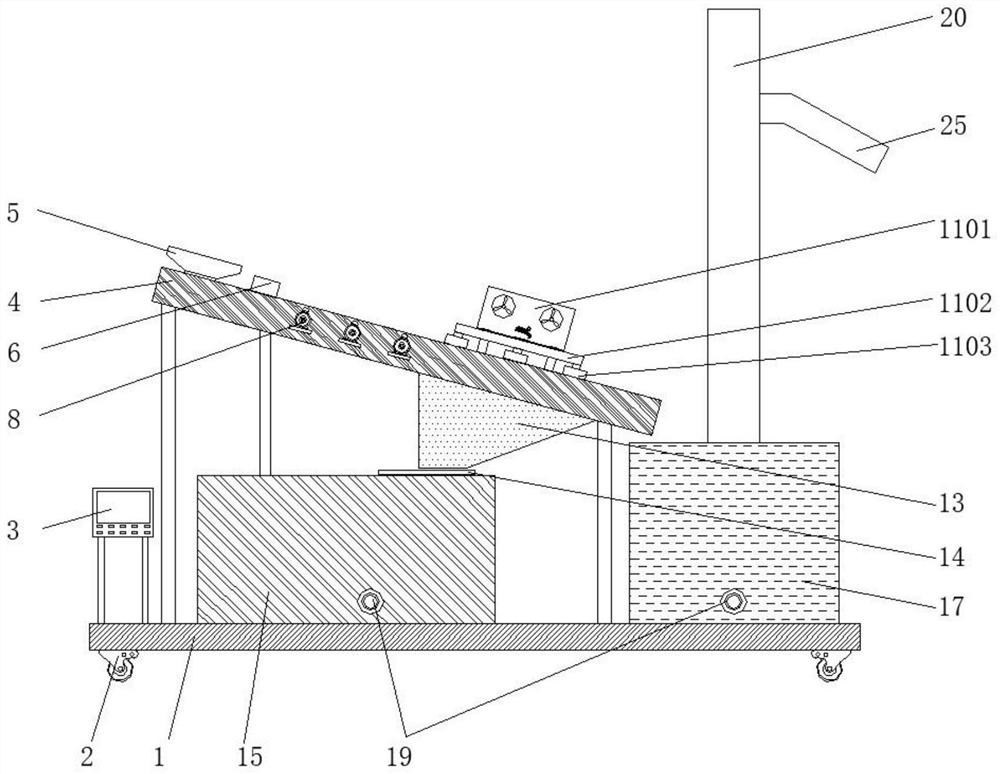

Automatic feeding machine for CPVC cable protection pipe production

InactiveCN113200281AIncrease cleaning powerConvenient loading operationPackagingSupporting framesElectric machineryProcess engineering

The invention discloses an automatic feeding machine for CPVC cable protection pipe production. The automatic feeding machine comprises a base, a first motor, an air drying mechanism and a storage box, the air drying mechanism is fixed on the upper end face of a first conveying channel, a first draining plate is arranged on the lower side of the air drying mechanism, and a water storage tank is arranged on the lower side of the first conveying channel. A water pump is fixed to the inner bottom of the water storage tank, the storage box is fixed to the right side of the upper end face of the base, a second conveying channel is fixed to the upper end face of a second draining plate, and openings are formed in the left side and the right side of the bottom of the second conveying channel. According to the automatic feeding machine for CPVC cable protection pipe production, in the process that granular raw materials roll downwards along the first conveying channel, water in the water storage tank can be sprayed out through a water passing channel and a water spraying head in sequence under the action of a water pump, the raw materials are conveniently cleaned, then a rotating brush rotates anticlockwise, the cleaning strength is conveniently enhanced, then an air spraying head sprays air downwards, and the cleaned raw materials can be air-dried conveniently.

Owner:江苏弛信管业科技有限公司

Light steel protecting window

PendingCN110778264AIncrease wind flowEasy to air dryFixed grillesOther drying apparatusHandrailVisor

The invention discloses a light steel protecting window. The window comprises a protecting window body, a telescopic sun shield, hooks, a hanging rod, an outer guardrail plate and sliding blocks, thefront plane of the protecting window body is provided with a window, a notch is formed in the corresponding rear plane of the window, the telescopic sun shield is arranged at the upper end of the rearplane notch of the protecting window body through screws, the hooks are arranged on the two sides of the lower end of the telescopic sun shield, handrails of the two sides of the protecting window protection are telescopic rods, the outer guardrail plate is arranged at the protecting window body rear plane notch, and is fastened with the handrails of the two sides in a welding mode, the hanging rod is arranged between the telescopic sun shield and the upper plane of the outer guardrail plate, sliding grooves are formed in the inner sides of the telescopic rods at the upper ends of the handrails at the two sides of the protecting window body, the sliding blocks are matched with the sliding grooves, and a push rod is used for connecting the left side sliding block with the right sliding block. According to the light steel protecting window, the outer guardrail plate can freely move back and forth through a main telescopic rod, the forward extending distance of the protecting window is increased, the space is conveniently and reasonably utilized, and the window is simple in structure and convenient to use.

Owner:湖南吉人住工装配式建筑有限公司

A dehumidification device for small electromechanical equipment

ActiveCN109068547BEasy to blow operationEasy to air dryCooling/ventilation/heating modificationsElectric machineryCoil spring

Owner:UNIV FOR SCI & TECH ZHENGZHOU

Potato detumescence patch

A provided potato detumescence patch comprises a fixed patch body, the middle of the fixed patch body protrudes upwards, so that a containing cavity is formed in the bottom face of the fixed patch body, meanwhile, an attaching part is formed on the outer edge of the bottom face of the fixed patch body, and a peelable release patch body adheres to the attaching part; and a potato tanning piece is placed in the containing cavity, and an extruding part which protrudes outwards and is used for extruding potato pieces to soften the potato pieces or rubbing the potatoes into mashed potatoes is arranged on one side, facing the release patch, of the potato tanning piece. The potato detumescence patch has the advantages of being convenient to fix, effectively moisturizing and improving the detumescence effect of the potato chip.

Owner:WENZHOU PEOPLES HOSPITAL

Sizing device for fabric processing

PendingCN113046950AEasy to remove dustReduce sizeMechanical cleaningPressure cleaningDust controlStructural engineering

The invention discloses a sizing device for fabric processing. The sizing device comprises a base, a guide mechanism and a second support, an air heater is fixed to the right side of the top of a cover frame, air outlet channels are fixed to the left side and the right side of the inner side of the second support, a stirring column is rotationally connected to the inner side of a storage box, and a material conveying pipeline penetrates through the top of the material storage box and is fixed between supporting plates. According to the sizing device for fabric processing, after a rotating door is opened by a worker, a fabric can penetrate through a material penetrating hole in the left side of the cover frame, sequentially bypass a first rotating rod and a second rotating rod and then penetrate out of a material penetrating hole in the right side of the cover frame, then limiting sleeves can be manually moved front and back to be close to each other, and the fabric is conveniently limited; the limiting sleeves can be fixed by tightening bolts, then the worker leaves the cover frame and closes the rotating door, a second rotating rod can rotate under the action of a first motor so as to drive the fabric to move rightwards in order, and subsequent dust removal, sizing and air drying operations can be completed conveniently, orderly and efficiently.

Owner:田峰

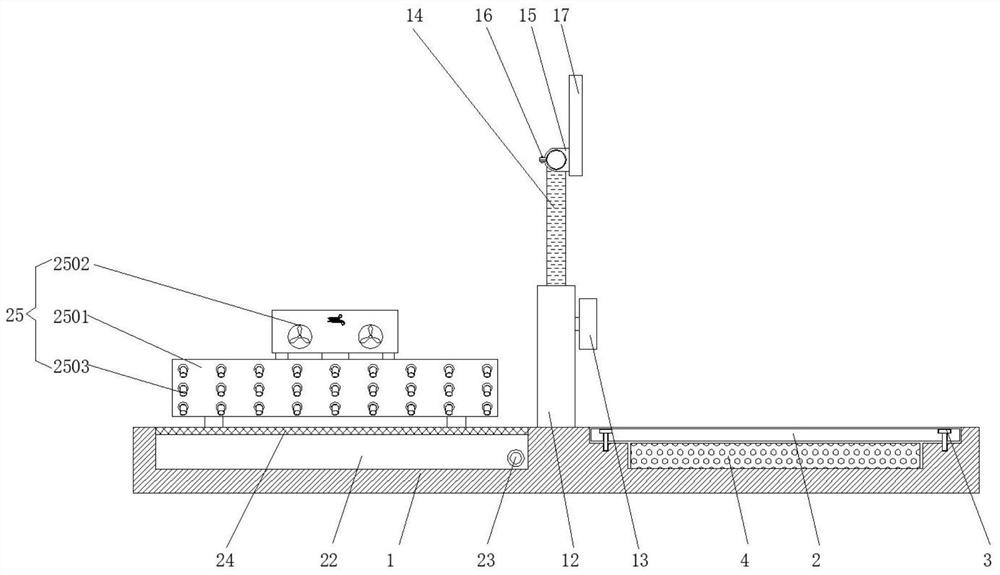

Air-drying equipment for aerated concrete blocks

InactiveCN111609705AEasy to move directionEasy to control the direction of movementDrying machine combinationsDrying gas arrangementsBrickEngineering

The invention discloses air-drying equipment for aerated concrete blocks, and belongs to the field of aerated bricks. The air-drying equipment comprises a base, wherein a conveyor belt support frame is arranged on the base; a conveyor belt is arranged on the conveyor belt support frame; supporting columns are arranged on the base; a top roof is arranged at the top ends of the supporting columns; aplurality of sets of heat dissipation fans are mounted at the lower surface of the top roof; the top roof is provided with a dryer; the base is provided with a sliding plate; one side of the base isprovided with a fixing frame; lifting rods are arranged on the fixing frame; the top ends of the lifting rods are provided with a top plate; an air-drying frame is in inserted connection through an insertion plate and an insertion opening of the fixing frame; the air-drying frame is provided with a plurality of partition plates; the air-drying frame is provided with a fan; the fan is electricallyconnected to a storage battery; and guide wheels are arranged at the bottom end of the air-drying frame. According to the air-drying equipment for the aerated concrete blocks, the heat dissipation fans are used for air blowing and the dryer is used for preliminary drying by removing water on the aerated blocks so as to avoid stickiness of the aerated blocks; and the fan is turned on while the aerated blocks on the air-drying frame are naturally air-dried so as to speed up the air-drying effect and efficiency of the aerated blocks, improve working efficiency and effect, ensure safety and facilitate use.

Owner:叶辉星

A domestic waste incinerator based on wind power transmission

The invention relates to the technical field of incineration equipment, in particular to a domestic waste incinerator based on wind power transmission. The domestic waste incinerator based on the windpower transmission comprises a furnace body, a base, a motor, a transmission shaft, a combustion chamber, a feeding door, a material blocking plate and an oil supply rod; the base is fixedly connected to the bottom of the furnace body, and a plurality of air inlet holes are formed in the base; and the motor is fixedly connected to the middle of the lower end of the base; the lower end of the transmission shaft is fixedly connected to a rotating shaft of the motor, a plurality of air blast blades are fixedly connected to the position, near the base, of the transmission shaft, and the upper endof the transmission shaft is fixedly connected to the bottom of the combustion chamber; and the combustion chamber is positioned at the central position of the inner part of the furnace body. According to the domestic waste incinerator based on the wind power transmission, the structure is simple, the usage is convenient, the incineration efficiency is high, domestic waste at the bottom of the furnace body is subjected to stirring and incision by arranging a stirring module, air drying and rising are convenient, the feeding efficiency is improved, and then the incineration efficiency is improved, the domestic waste falling into the combustion chamber is subjected to sufficient and even oil injection by arranging a plurality of successively increasing oil injection rods, the domestic wastecan be burned more fully, and the incineration efficiency can be improved.

Owner:徐州劲硕电气科技有限公司

Method for producing belite-gypsum material by roasting sludge and waste gypsum with fluidized fluidized furnace

ActiveCN104446068BReduce grinding energy consumptionGrinding energy consumption is goodSludgeHigh water content

Owner:长沙紫宸科技开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com