Pipeline inner detector loop test platform and test method thereof

A technology of internal detector and loop test, applied in the direction of material magnetic variable, etc., can solve the problems of insufficient height, insufficient wear resistance, fault detection accuracy and positioning accuracy, etc., so as to reduce the probability of failure and meet the requirements of use effect of demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

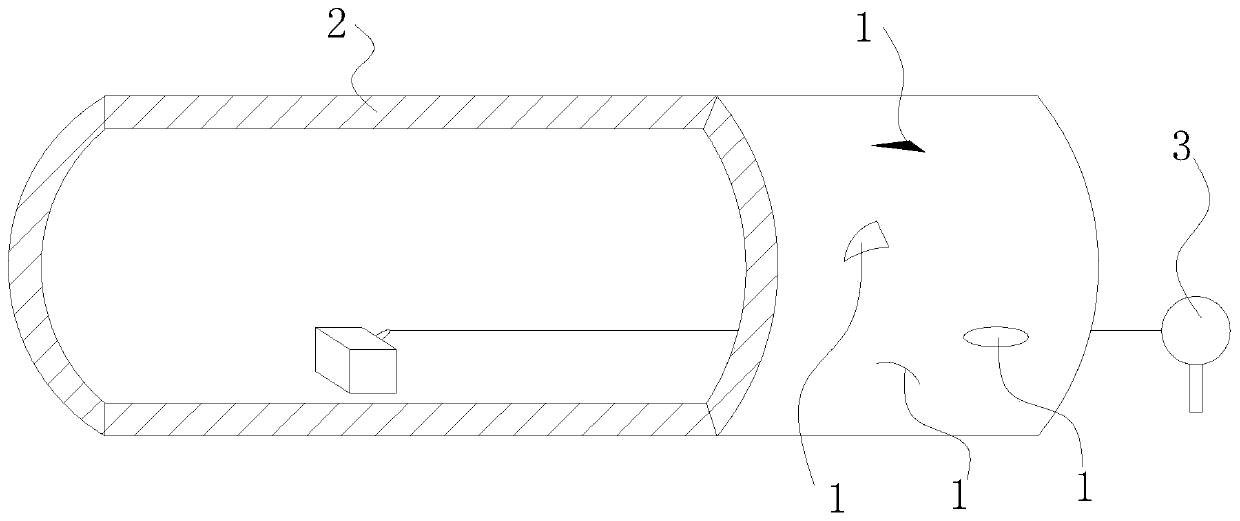

[0031] Such as figure 1 As shown, the present preferred embodiment provides a loop test platform for detectors in pipelines, the test platform includes a pipeline 2 and a power system with a defective sample 1 preset on the hollow pipe wall, and the outside of the pipe wall of the pipeline 2 is coated with Covered with anti-corrosion layer. The power system includes traction automatic control device 3, working condition experiment device, electrical power supply device and instrument control device.

[0032] Wherein, traction automatic control device 3 is used for providing traction force for inner detector, preferably, traction automatic control device 3 comprises winch, and winch provides inner detector and carries out traction. The working condition experiment device is used to fill the pipeline 2 with liquid or gas to test the working environment in the submarine pipeline. The electrical power supply unit supplies power to devices within the test platform. The instrumen...

Embodiment 2

[0053] This preferred embodiment provides an in-pipeline detector loop test platform, the structure of which is basically the same as that of the first preferred embodiment. The test platform includes a pipe 2 with a defective sample 1 preset on the hollow pipe wall and a power system; the power system includes a traction automatic control device 3, a working condition experiment device, an electrical power supply device and an instrument control device. Wherein, the traction automatic control device 3 is used to provide traction for the inner detector. Preferably, the traction automatic control device 3 includes a hoist, and the hoist provides traction to the inner detector. The working condition experiment device is used to fill the pipeline 2 with liquid or gas to test the working environment in the submarine pipeline. The electrical power supply unit supplies power to devices within the test platform. The instrument control device includes a controller and a plurality of ...

Embodiment 3

[0059] This preferred embodiment provides a test method for the wear resistance of the inner detector by using the least number of tests on the loop test platform of the inner detector in the pipeline, and its structure is basically the same as that of the first preferred embodiment.

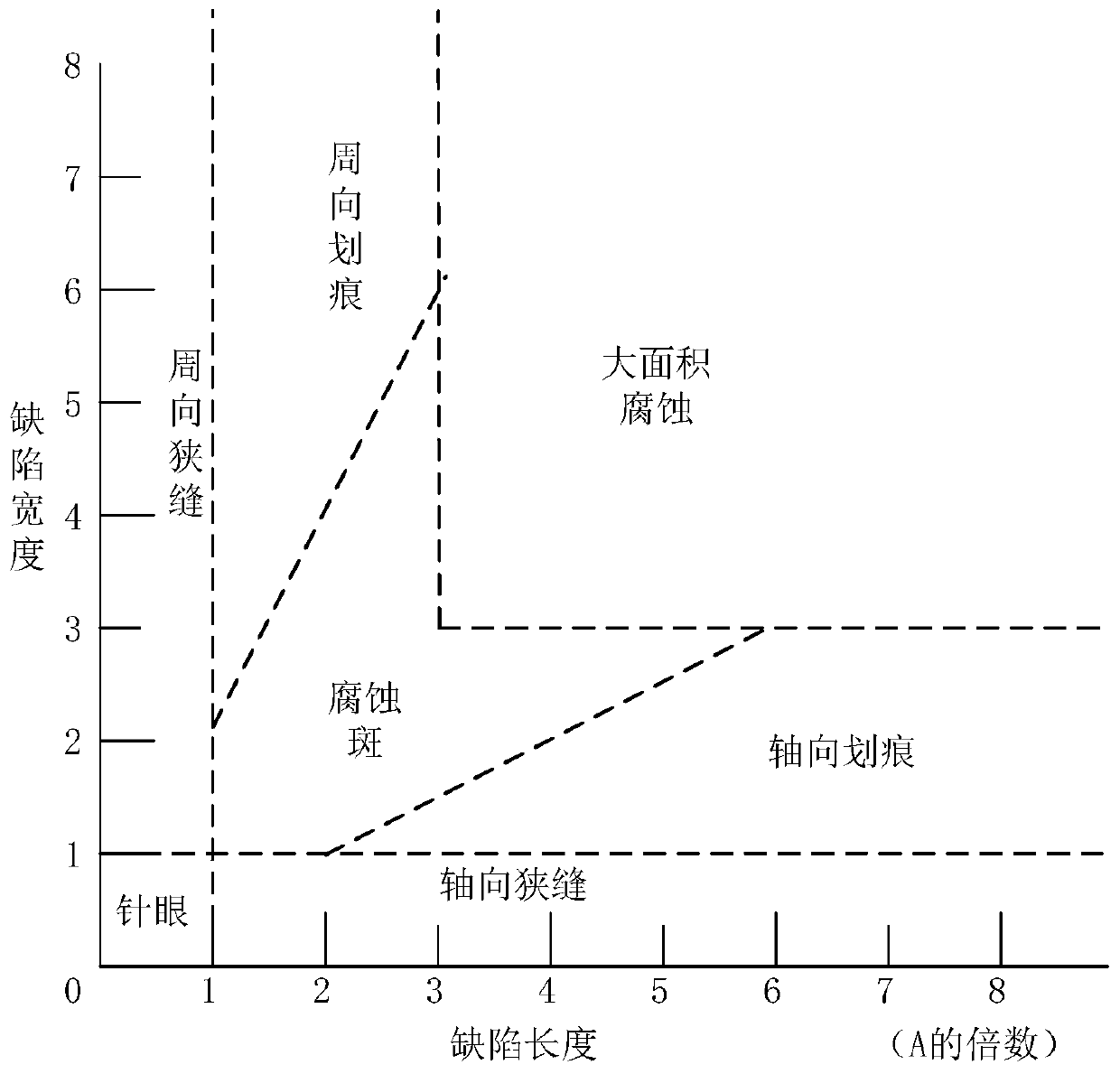

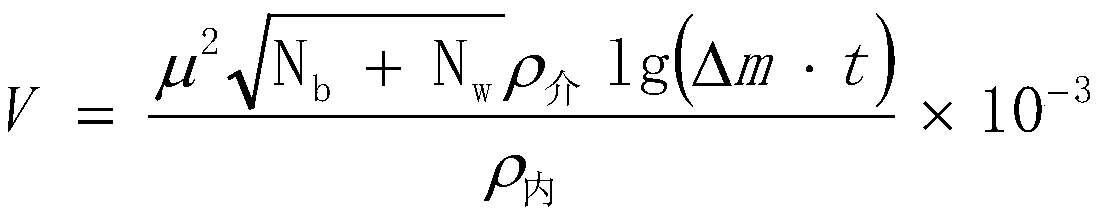

[0060] First, manually detect and record parameters such as the quality of the internal detector, material density, medium density under different experimental conditions, the number of detector petals, and the number of elbows in the pipeline 2; secondly, use the traction automatic control device 3 as the internal detector Provide traction to run the inner detector in the experimental pipeline in the experimental inner detector loop test bench. After each experiment, record the current weight and running time of the inner detector, count the weight change and total running time of the inner detector up to the current experiment, put the statistical results in Table 1, and obtain the wear resista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com