Cold matching hot pot dip and preparation method thereof

A technology for hot pot and dipping sauce, applied in food science and other directions, can solve problems such as loss of flavor, and achieve the effects of controlling microbial indicators, reducing bacterial contamination, and retaining traditional flavors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

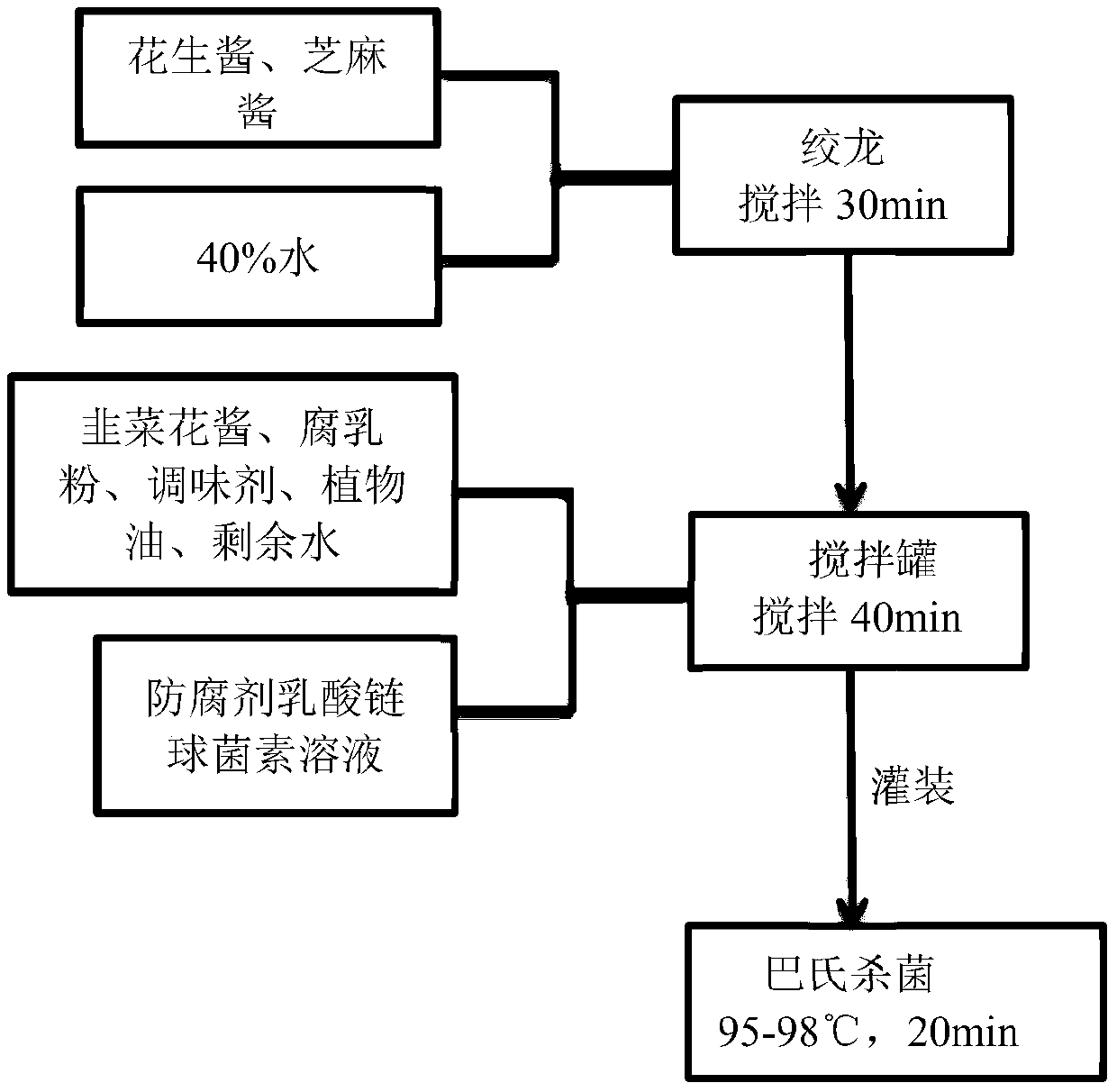

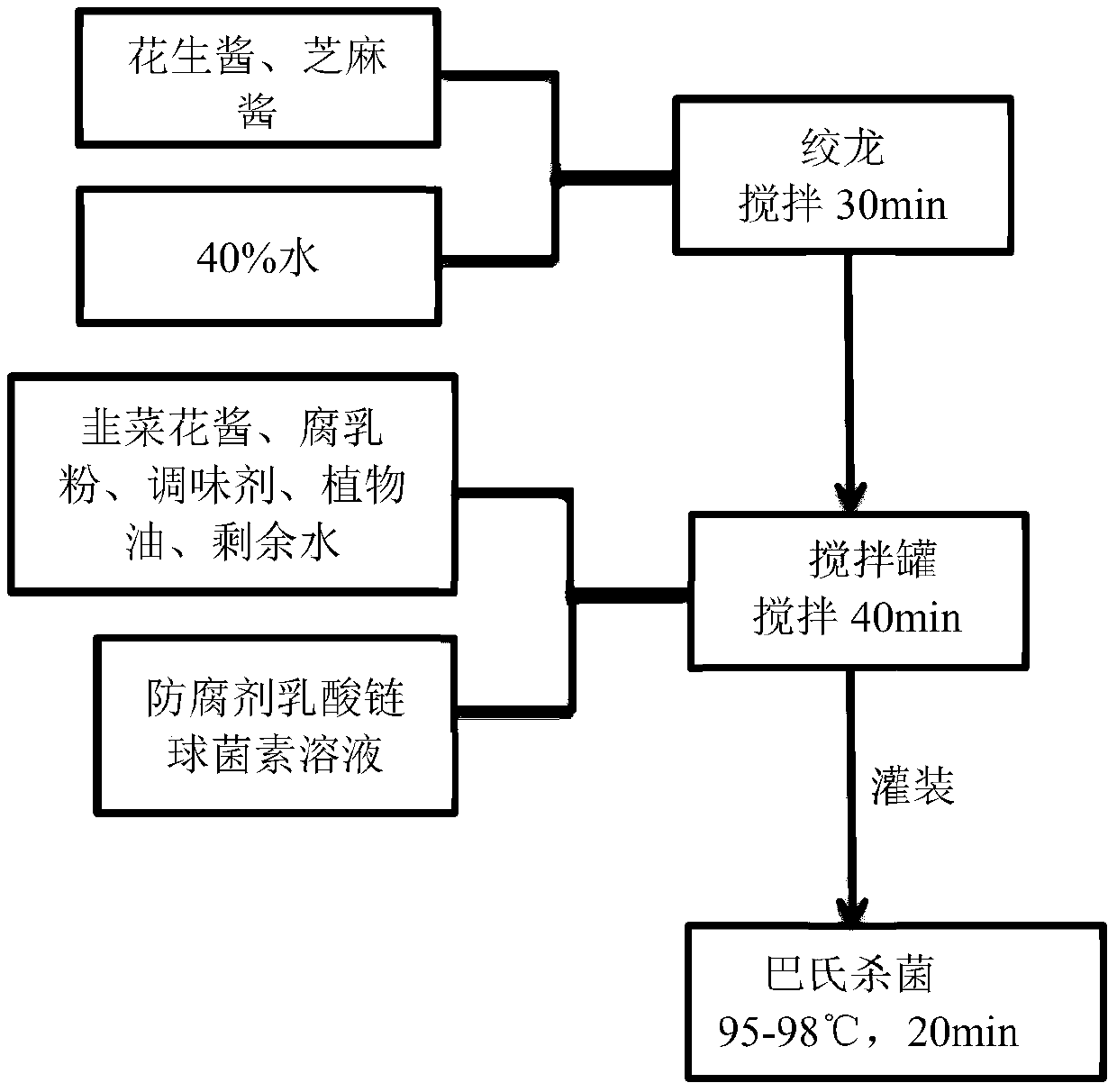

[0025] A preparation method for cold hot pot dipping sauce as described above, comprising the following steps,

[0026] 1) Dissolve nisin completely in water at 30°C-32°C for later use;

[0027] 2) Add peanut butter, sesame paste and 40% of the water in the formula to the auger, continue to stir until the material is uniform, and beat the evenly stirred material to the blending tank;

[0028] 3) According to the proportion of the formula, add the leek flower sauce, flavoring agent, and nisin mixture into the blending tank, start stirring until the materials are uniform;

[0029] 4) After stirring evenly, put the material into the finished product tank through the emulsification pump, and prepare for filling;

[0030] 5) When the water temperature of the water bath rises to 95°C-98°C, put the airtight product into the water bath, and the product will take 25-30 minutes from entering the hot water pot to leaving the hot water pot to ensure that the product is hot water The tem...

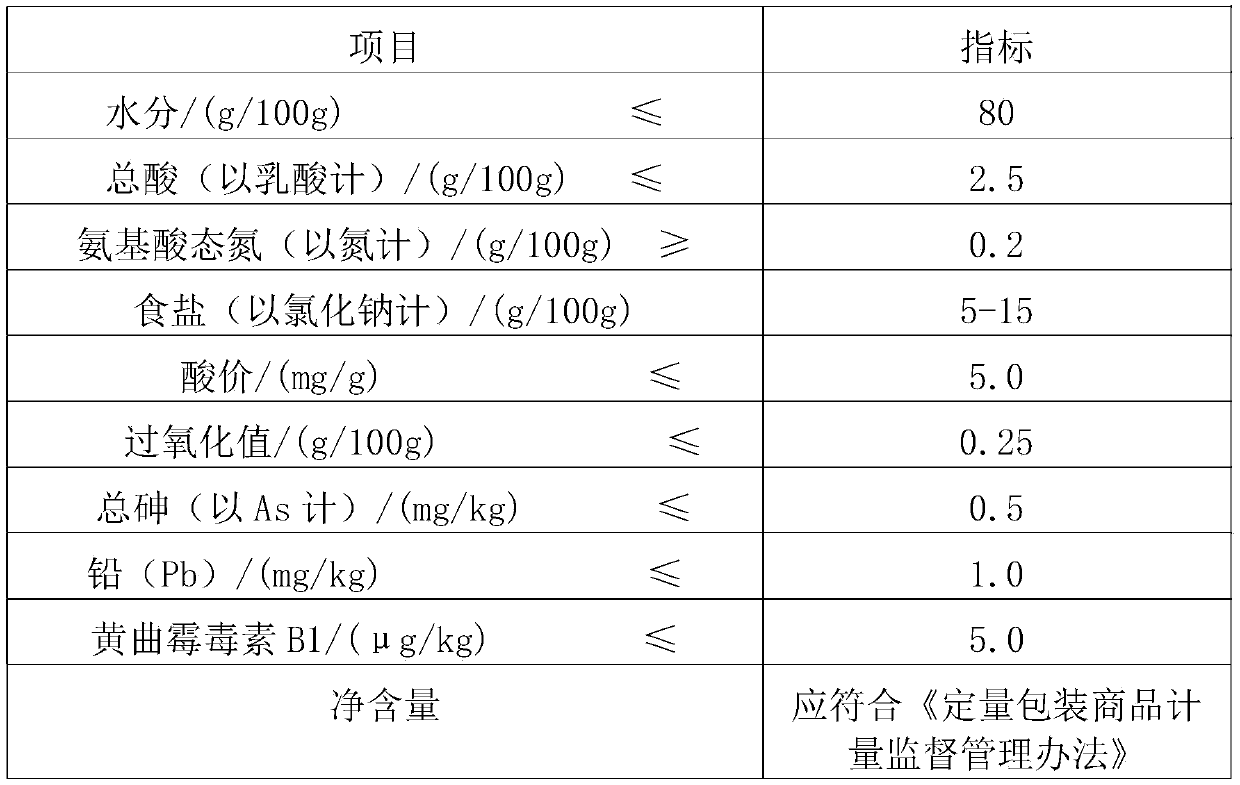

Embodiment 1

[0032] Adopt the above method to prepare cold hot pot dipping sauce, its raw material is made up of the following components by weight,

[0033] 30.635 parts of drinking water; 20 parts of peanut butter; 10 parts of sesame paste; 20 parts of chive flower sauce; 7 parts of vegetable oil; 0.3 parts of flavor enhancer; 0.05 parts of sesame oil essence; the peanut butter and sesame paste are 120 mesh, and the chive flower sauce is 80 mesh. The monosodium glutamate is sodium glutamate, and the sesame oil essence is obtained by supercritical extraction of sesame. The vegetable oil is soybean oil; the fermented bean curd powder is obtained by powdering the fermented bean curd at high temperature. Nisin is obtained from lactic acid fermentation.

Embodiment 2

[0035] Adopt the above method to prepare cold hot pot dipping sauce, its raw material is made up of the following components by weight,

[0036] 32.64 parts of drinking water; 25 parts of peanut butter; 7 parts of sesame paste; 15 parts of chive flower sauce; 7 parts of vegetable oil; 0.3 part of flavor enhancer; 0.05 part of sesame oil essence; monosodium glutamate is monosodium glutamate, and sesame oil essence is obtained by supercritical extraction of sesame. The peanut butter and sesame paste are 120 mesh, and the chive flower sauce is 80 mesh. The vegetable oil is obtained by pressing one or two kinds of oil crops among peanuts, soybeans and sunflower seeds; the fermented bean curd powder is obtained by spraying fermented bean curd at high temperature. Nisin is obtained from lactic acid fermentation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com