Paddy magnetic separator

A magnetic separator and paddy technology, which is applied in paddy magnetic separation and rice processing fields, can solve the problems of magnetic metal residues, etc., and achieve the effect of increasing the area, improving the efficiency of magnetic separation, and improving the effect of magnetic separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following is further described in detail through specific implementation methods:

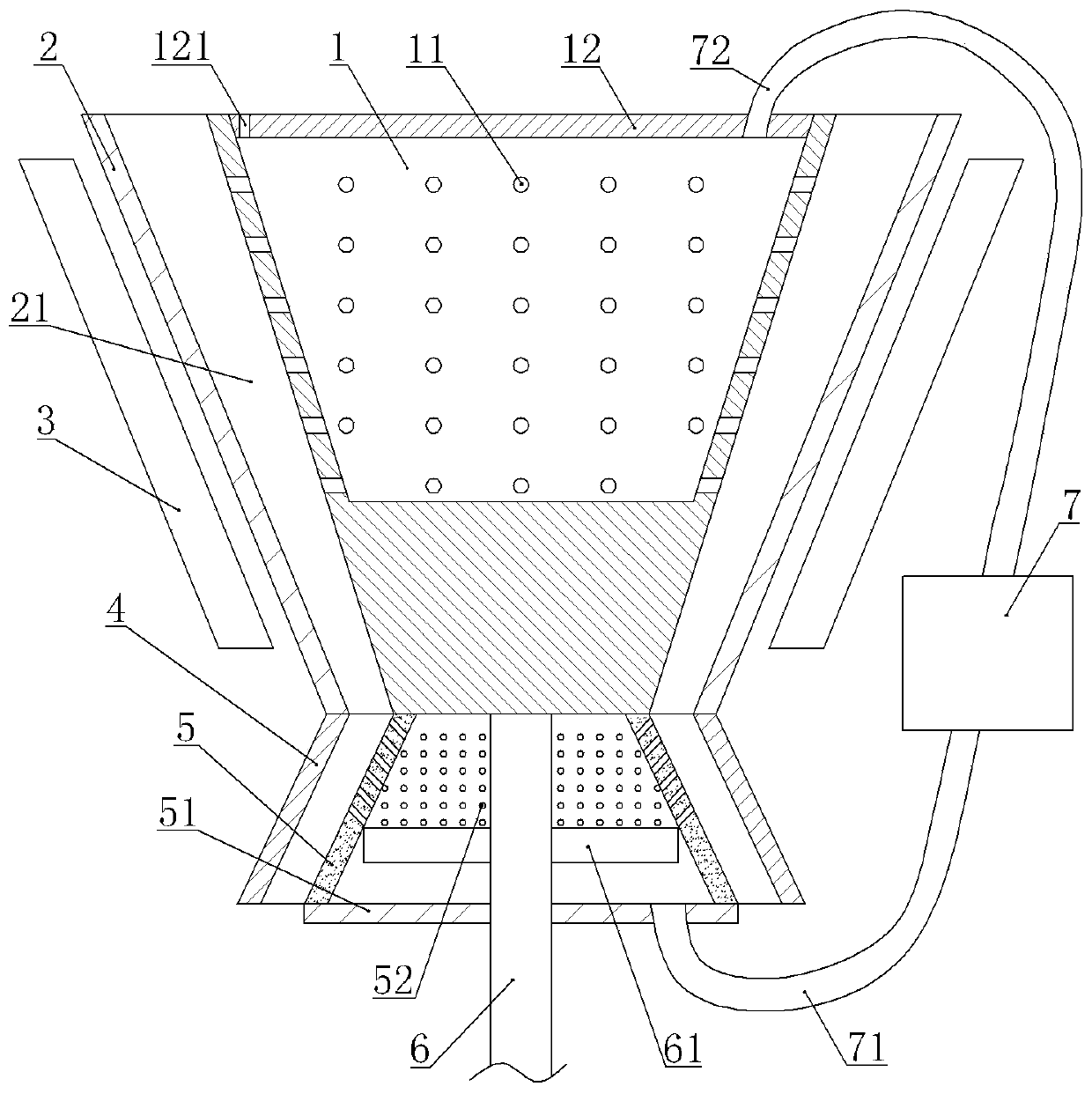

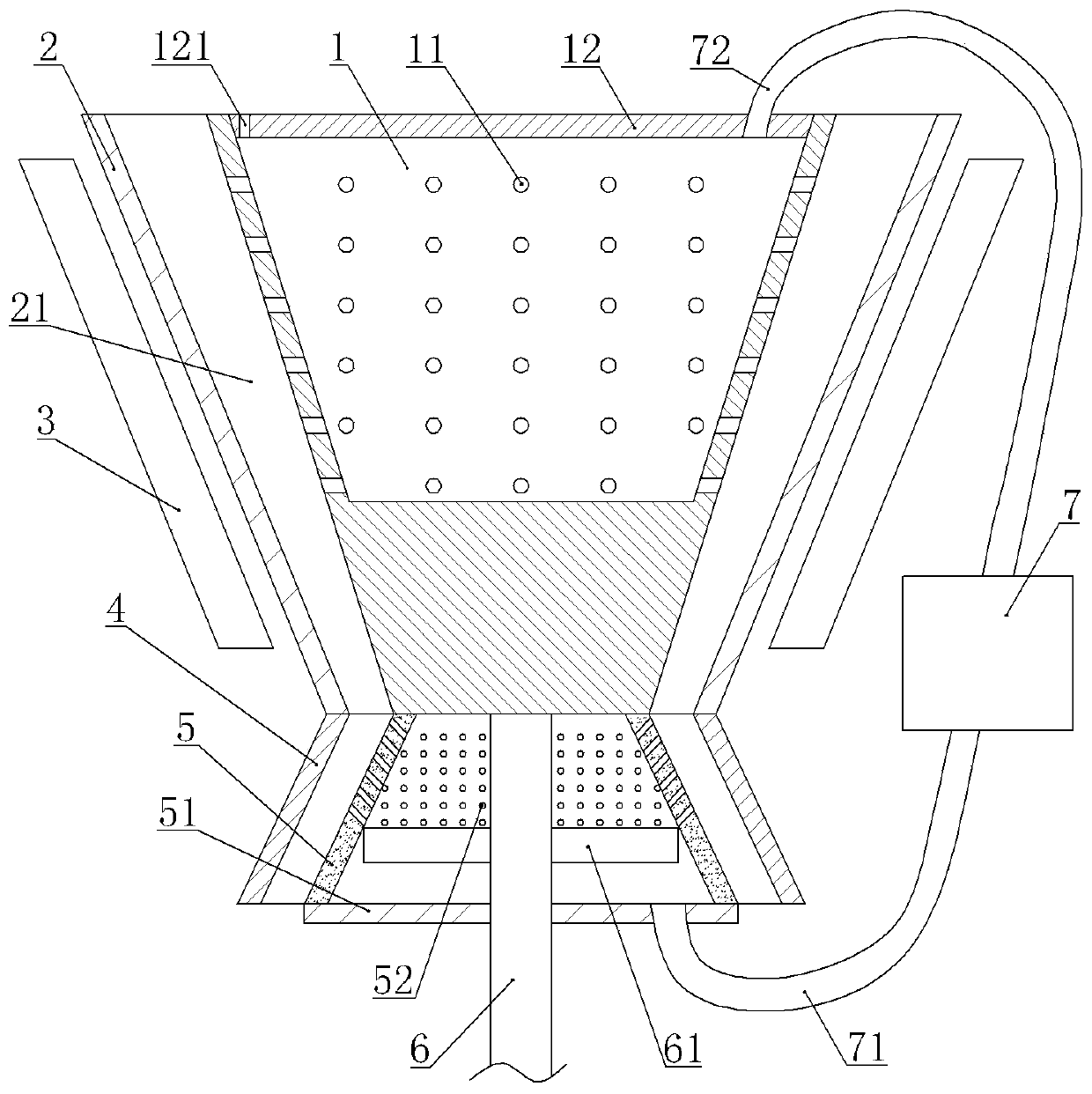

[0025] The reference signs in the drawings of the description include: drum 1, discharge hole 11, cover body 12, balance hole 121, retaining cylinder 2, magnetic separation chamber 21, magnetic part 3, guide ring 4, outer cover 5, bottom cover 51 , air vent 52, rotating shaft 6, axial flow blade 61, dust removal box 7, air intake pipe 71, negative pressure pipe 72.

[0026] The embodiment is basically as attached figure 1 Shown:

[0027] The rice magnetic separator includes a frame, an acceleration mechanism and an adsorption mechanism. The acceleration mechanism includes a driving member, a rotating drum 1 and a vertically arranged rotating shaft 6. The rotating drum 1 is connected to the frame in rotation, and the top of the rotating shaft 6 is welded to the bottom of the rotating drum 1. , the middle and upper parts of the drum 1 are provided with an inner cavity, and the top of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com