Two-row chain pre-pull and joint dismantling device

A chain and pre-pulling technology, used in metal chains, tools for repairing chains by metal processing, manufacturing tools, etc., can solve the problems of high precision requirements, reduced product quality, time-consuming and labor-intensive, etc., to improve chain quality, increase Contact area, the effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

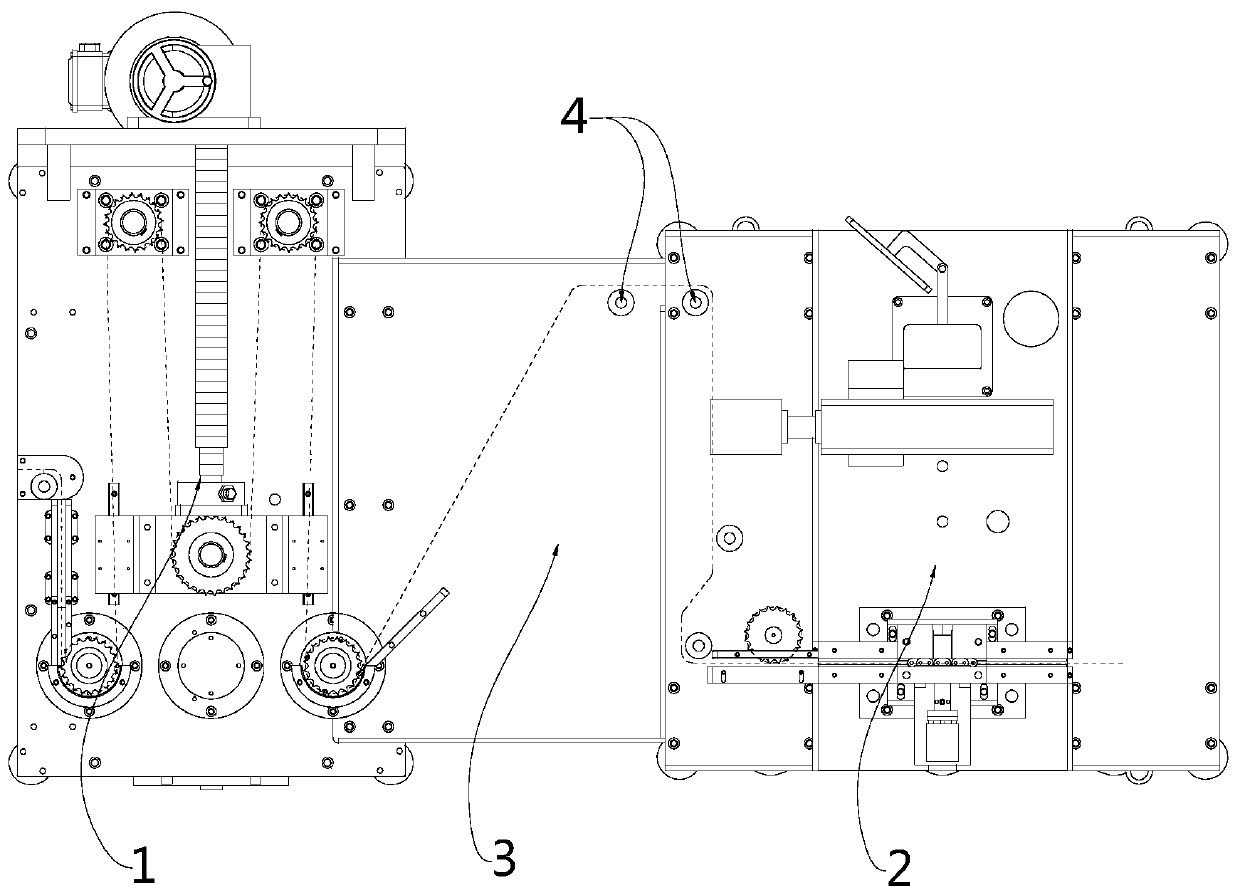

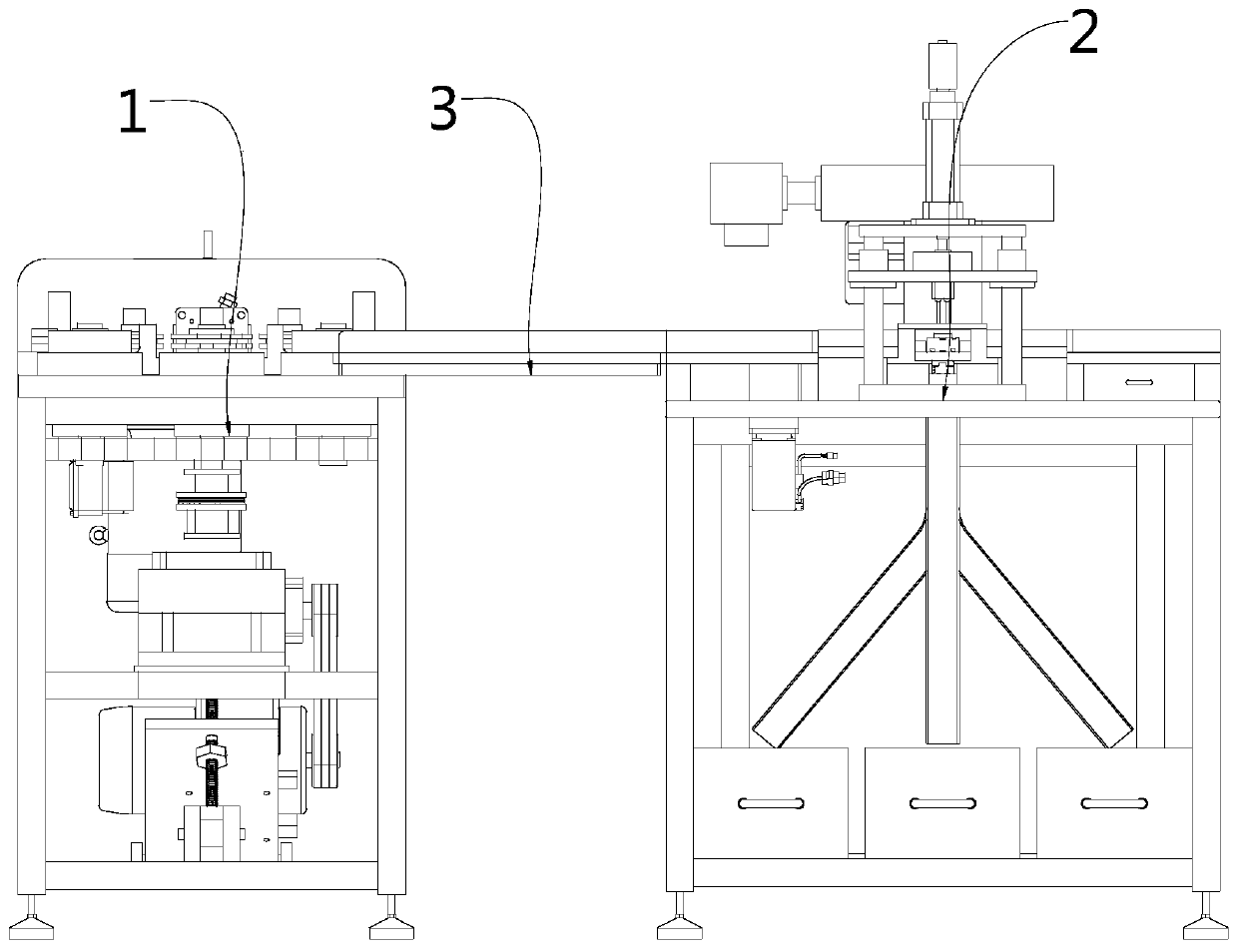

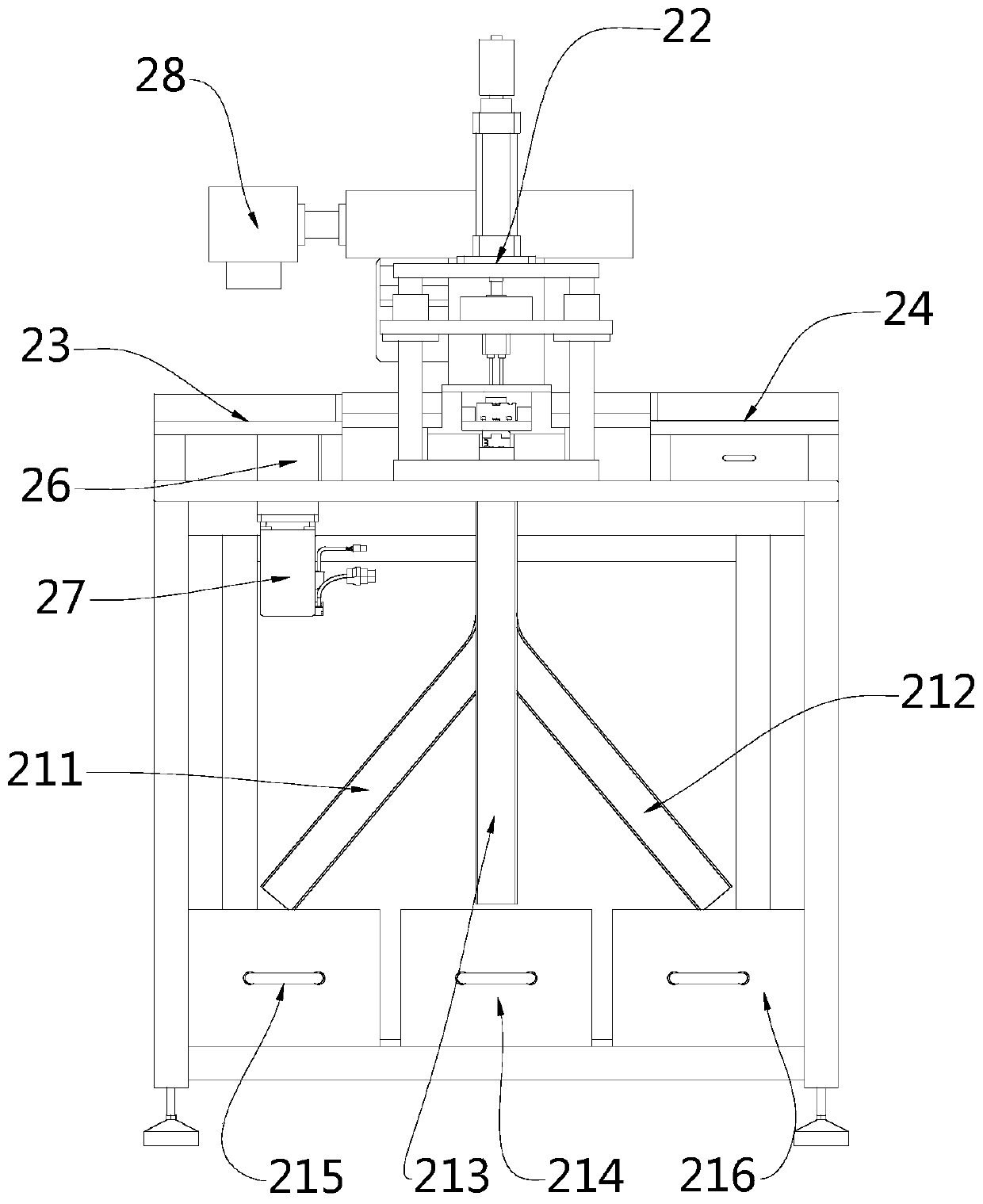

[0040] Embodiment: a double-row chain pre-drawing and dismantling device, the structure is as follows Figure 1 to Figure 16 As shown, it includes a pre-tensioning mechanism 1 and a joint removal mechanism 2. A chain stacking plate 3 is provided between the pre-tensioning mechanism 1 and the joint removal mechanism 2. The joint removal mechanism 2 includes a workbench 21 on which a dismantling The joint module 22, the two ends of the dismantling module 22 are respectively provided with a chain engaging channel 23 and a chain engaging channel 24, and the chain engaging channel 23 is provided with a driving sprocket 25, and the driving sprocket 25 is connected to a servo motor through a planetary reducer 26 A motor 27, a laser marking machine 28 is provided on the workbench 21 on one side of the chain meshing channel 23;

[0041] The dismantling module 22 includes a tooling mounting plate 40 arranged on the workbench 21, the tooling mounting plate 40 is provided with a dismantli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com