Auxiliary welding turnover machine for semitrailer frame

An auxiliary welding and semi-trailer technology, which is applied in auxiliary welding equipment, auxiliary devices, welding equipment, etc., can solve the problems of unguaranteed quality of the frame, obvious intermittent welds, and inability to operate continuously, achieving good sightlines, Avoid shaking or falling, and use a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be described in further detail below in conjunction with the accompanying drawings.

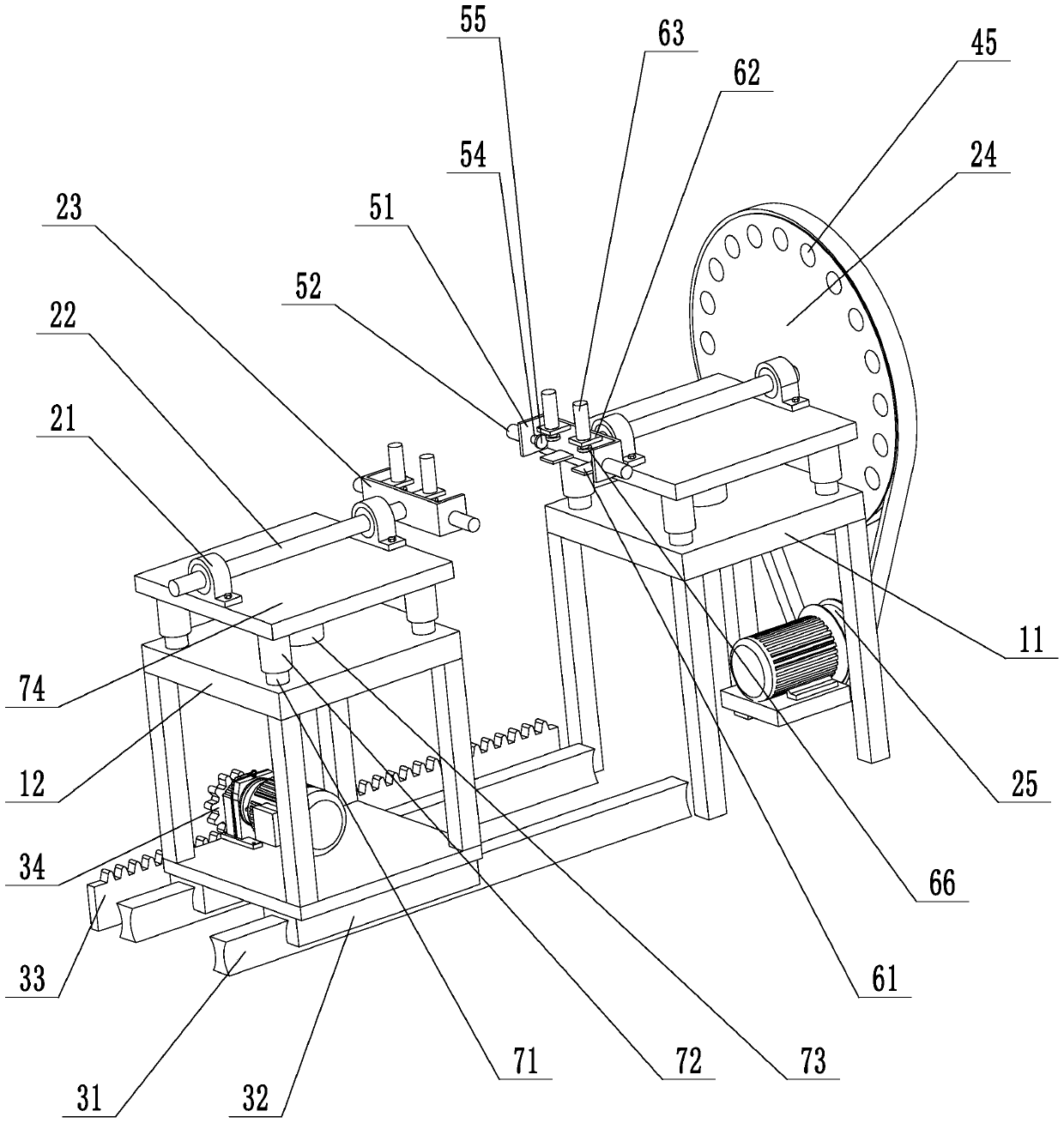

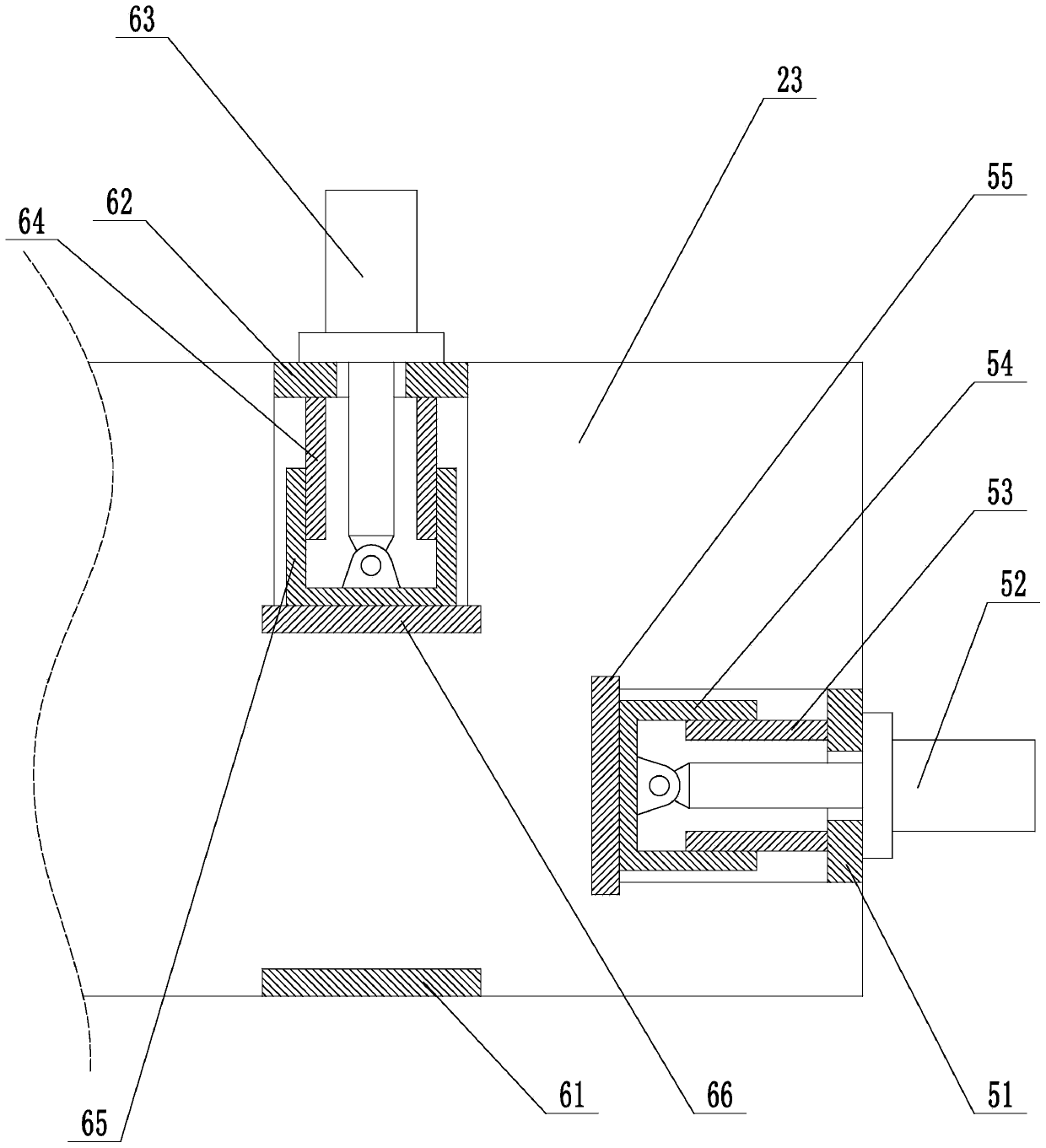

[0052] refer to figure 1 , is an auxiliary welding turning machine for a semi-trailer frame disclosed by the present invention, wherein the main body is the active turning platform 11 and the driven turning platform 12, and the remaining parts are installed on the driving turning platform 11 and the driven turning platform 12.

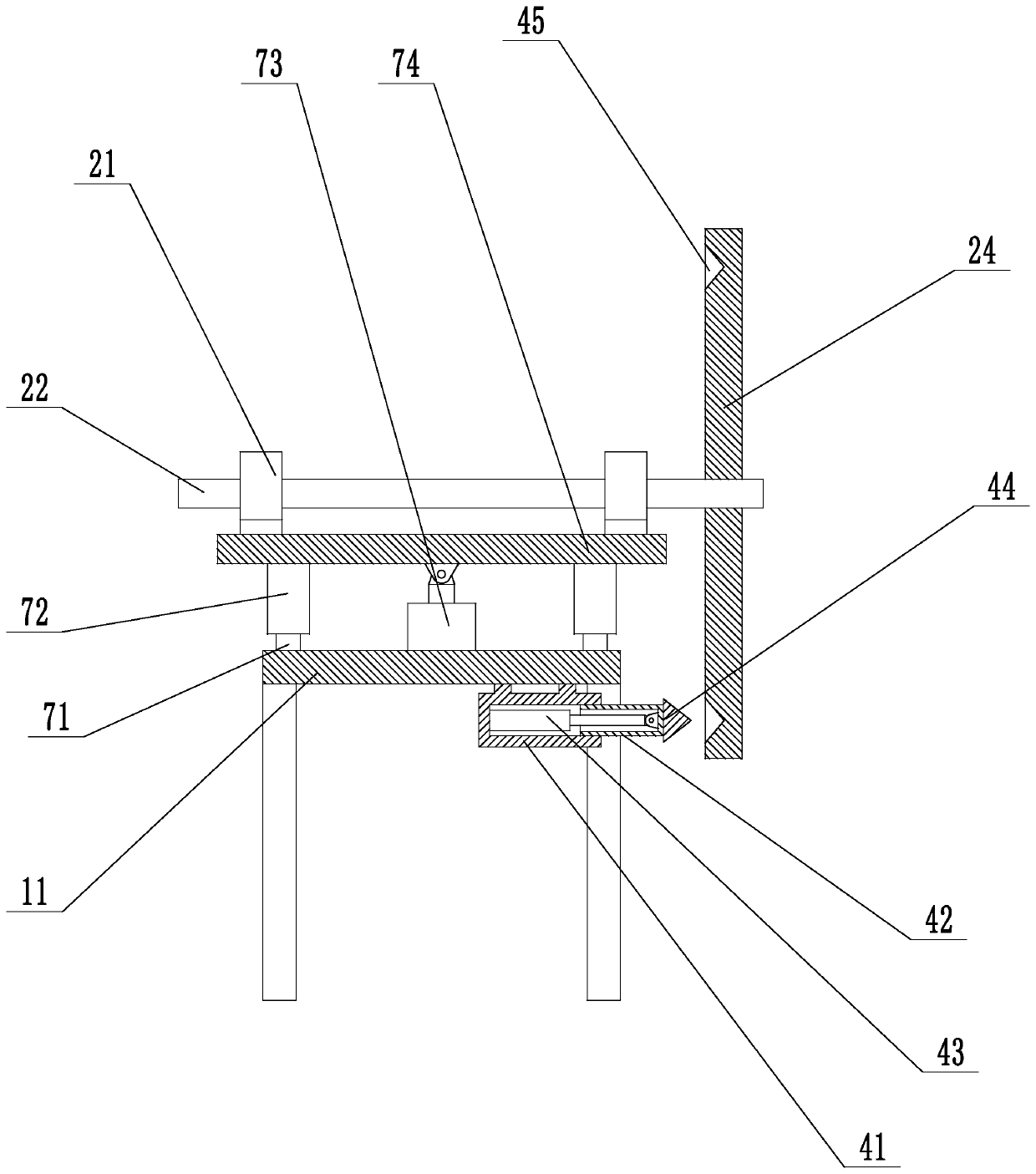

[0053] The active overturning table 11 is directly fixed on the floor of the workshop with anchor bolts or expansion bolts. Four corners on its upper surface are welded with four columns 71 respectively. A lifting hydraulic cylinder 73 is placed in the column 71 , the lower end of the lifting hydraulic cylinder 73 is hinged with the bottom surface of the column 71 , and the upper end is hinged with the top surface of the guide sleeve 72 . A workbench 74 is welded or bolted on the guide sleeve 72 and can move vertically under the push...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com