A method for repairing and treating the corroded part of the original composite layer of the tank body

A repair method and technology of treatment method, which are applied to the two types of repair treatment fields with different corrosion areas and different corrosion degrees of the original composite layer of the tank body, can solve the problems of large welding deposition surface, time-consuming and labor-intensive, waste of materials, etc. Welding deposited surface, simple and quick operation, anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

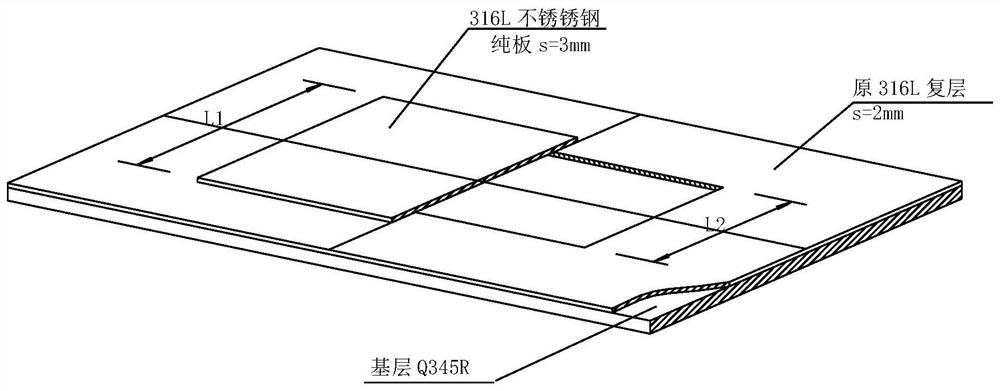

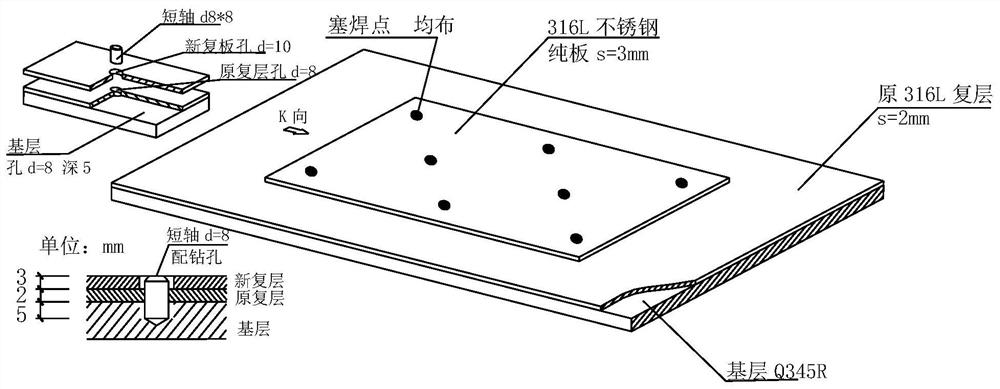

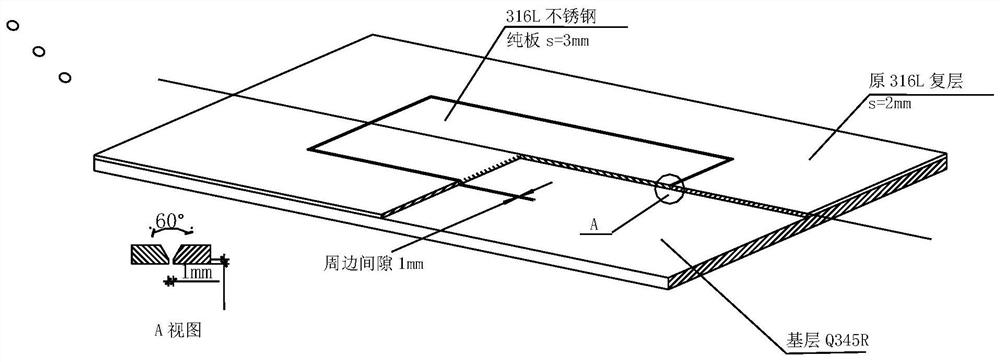

[0032] like figure 1 As shown in the figure, the original 316L stainless steel cladding is repaired by a "patch-type" veneer repair method using 316L stainless steel pure plate with s=3mm. , using "Ruiling" brand WS-315 high-frequency argon arc welding machine for welding.

[0033] specific measure:

[0034] Mechanically grind the original cladding of the rusted parts to be repaired until the metallic luster is exposed;

[0035] According to the size and area of the rusted part and the relevant technical requirements, the typesetting and blanking of the pure plate are carried out. The size should be slightly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com