Large loading machine for loading and unloading train skin materials

A technology of loading machines and materials, which is applied in the field of construction machinery, can solve the problems of excessive time to find faults and high work intensity of drivers, and achieve the effect of simple structure, reasonable design and saving working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

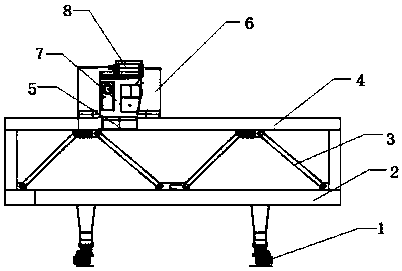

[0011] This embodiment provides a large-scale loading machine for loading and unloading materials on train skins, characterized in that: the large-scale loading machine for loading and unloading materials on train skins includes a traveling device (1), a vehicle frame (2) , Support reinforcement column (3), slide rail (4), slider (5), top mounting frame (6), driver's cab (7), three-in-one geared motor (8);

[0012] Among them: including the car frame (2), the lower part of the car frame (2) is provided with a running device (1), the car frame (2) is provided with a horizontal slide rail (4), and the slide rail (4) is fixed On the top of the car frame (2), a number of support reinforcement columns (3) are arranged between the slide rail (4) and the lower part of the car frame (2), and the top is slidably installed on the slide rail (4) through a slider (5). Mounting frame (6), driver's cab (7) is set and installed in the top mounting frame (6), and the top of slide rail (4) is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com