Method for realizing rapid growth of biological membrane in nitrosation process

A rapid growth and biofilm technology, applied in chemical instruments and methods, aerobic process treatment, sustainable biological treatment, etc., can solve the problems of long generation cycle, slow growth, and difficulty in enrichment and cultivation, and achieve high vigor and optimization Effect of treatment conditions, macrobiofilm growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

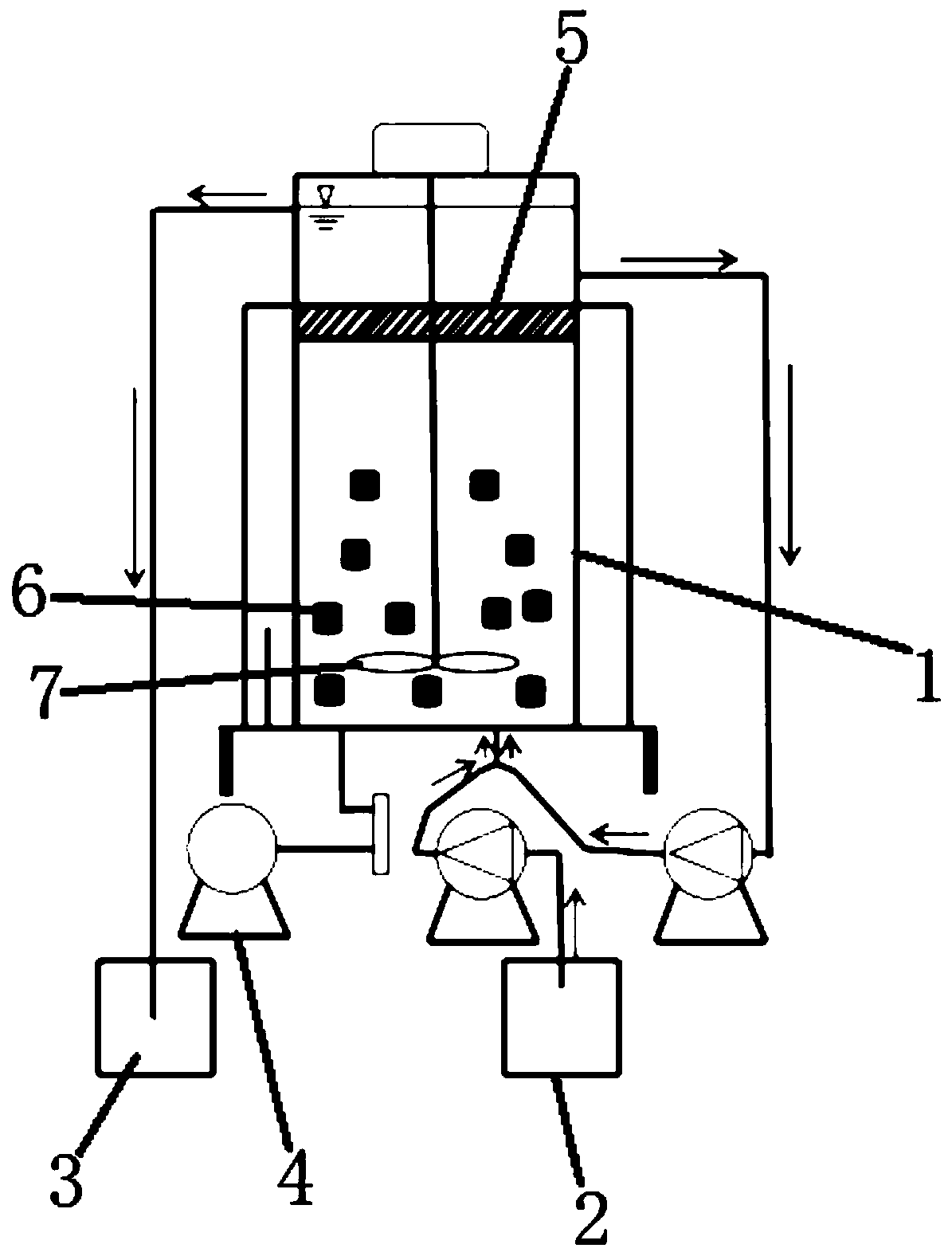

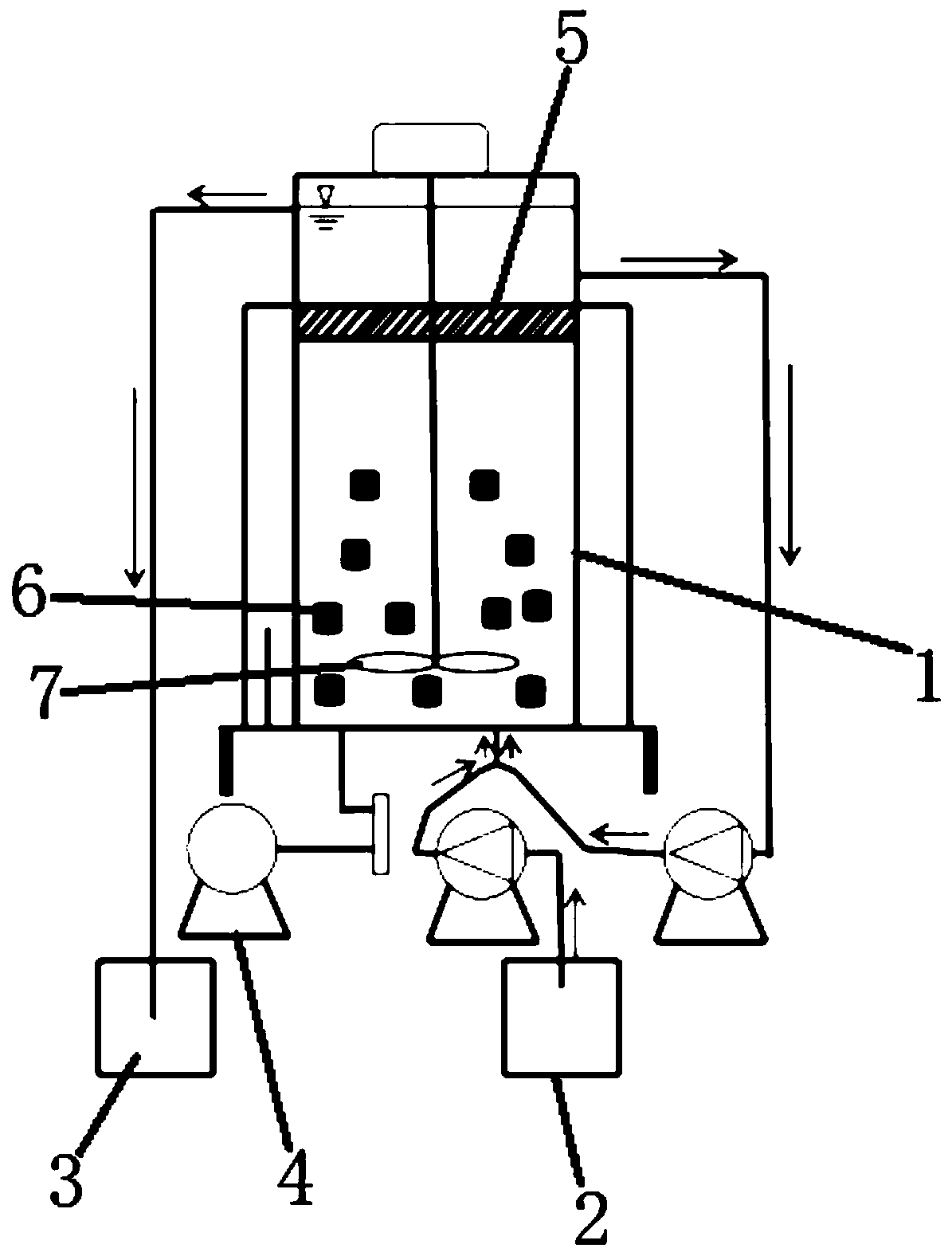

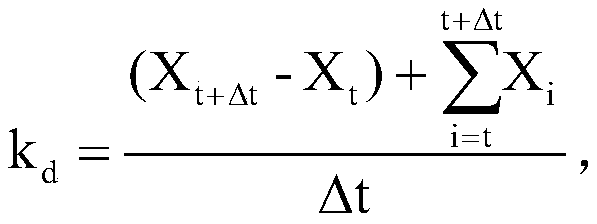

[0027] In this embodiment, the biofilm growth rate is measured by calculating the biofilm growth / separation rate under different operating modes and influent COD conditions, and the optimal condition for the fastest growth rate is determined. In order to achieve the above purpose, in this example, by inoculating mature nitrosative sludge, under continuous aeration and intermittent aeration conditions, the COD of the reactor influent was gradually increased, and the biofilm growth / separation rate was measured at each experimental stage.

[0028] The first step, the establishment of nitrosation process system

[0029] The 160-day stable nitrosation sludge was inoculated into the moving bed biofilm reactor (MBBR) with continuous aeration (RC) and RI with intermittent aeration (RI), respectively, in RC and RI reactors The sludge concentrations of the two reactors were 10449g SS / L and 9577g SS / L; the parameters of the two reactors were the same, the inner diameter was 15cm, the hei...

Embodiment 2

[0054] A method for realizing the rapid growth of biofilm in the nitrosation process. The method adopts a moving bed biofilm reactor system, and ammonia nitrogen wastewater is input into the moving bed biofilm reactor. Under continuous aeration conditions, the ammonia nitrogen wastewater is sub Nitrification treatment; in ammonia nitrogen wastewater, the mass concentration ratio of COD to ammonia nitrogen is 0.1.

[0055] Among them, in the ammonia nitrogen wastewater, the mass concentration of ammonia nitrogen is 320mg / L. The continuous aeration conditions are as follows: the aeration rate is 0.3L / min, and the dissolved oxygen content is 1.5mg / L. Nitrosification sludge was inoculated in the moving bed biofilm reactor. The internal temperature of the moving bed biofilm reactor was 31 °C. In the moving bed biofilm reactor, the influent flow rate of ammonia nitrogen wastewater is 0.75L / h, and the hydraulic retention time is 8h. In the moving bed biofilm reactor, the speed of ...

Embodiment 3

[0057] A method for realizing the rapid growth of biofilm in the nitrosation process. The method adopts a moving bed biofilm reactor system, and ammonia nitrogen wastewater is input into the moving bed biofilm reactor. Under continuous aeration conditions, the ammonia nitrogen wastewater is sub Nitrification treatment; in ammonia nitrogen wastewater, the mass concentration ratio of COD to ammonia nitrogen is 0.25.

[0058]Among them, in the ammonia nitrogen wastewater, the mass concentration of ammonia nitrogen is 280mg / L. The continuous aeration conditions are: the aeration rate is 0.5L / min, and the dissolved oxygen content is 0.5mg / L. Nitrosification sludge was inoculated in the moving bed biofilm reactor. The internal temperature of the moving bed biofilm reactor was 33°C. In the moving bed biofilm reactor, the influent flow rate of ammonia nitrogen wastewater is 0.35L / h, and the hydraulic retention time is 16h. In the moving bed biofilm reactor, the speed of the agitato...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap