High pressure nitrogen-low temperature liquid nitrogen composite fracturing method for oil and gas production increasing

A technology of low-temperature liquid nitrogen and high-pressure nitrogen, which is applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., can solve the problems of impossibility of proppant entering, improve the effect of fracturing and increase production, improve self-supporting ability, improve Effect of Reservoir Fracture Degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0033] A high-pressure nitrogen-low temperature liquid nitrogen composite fracturing method for increasing oil and gas production of the present invention comprises the following steps:

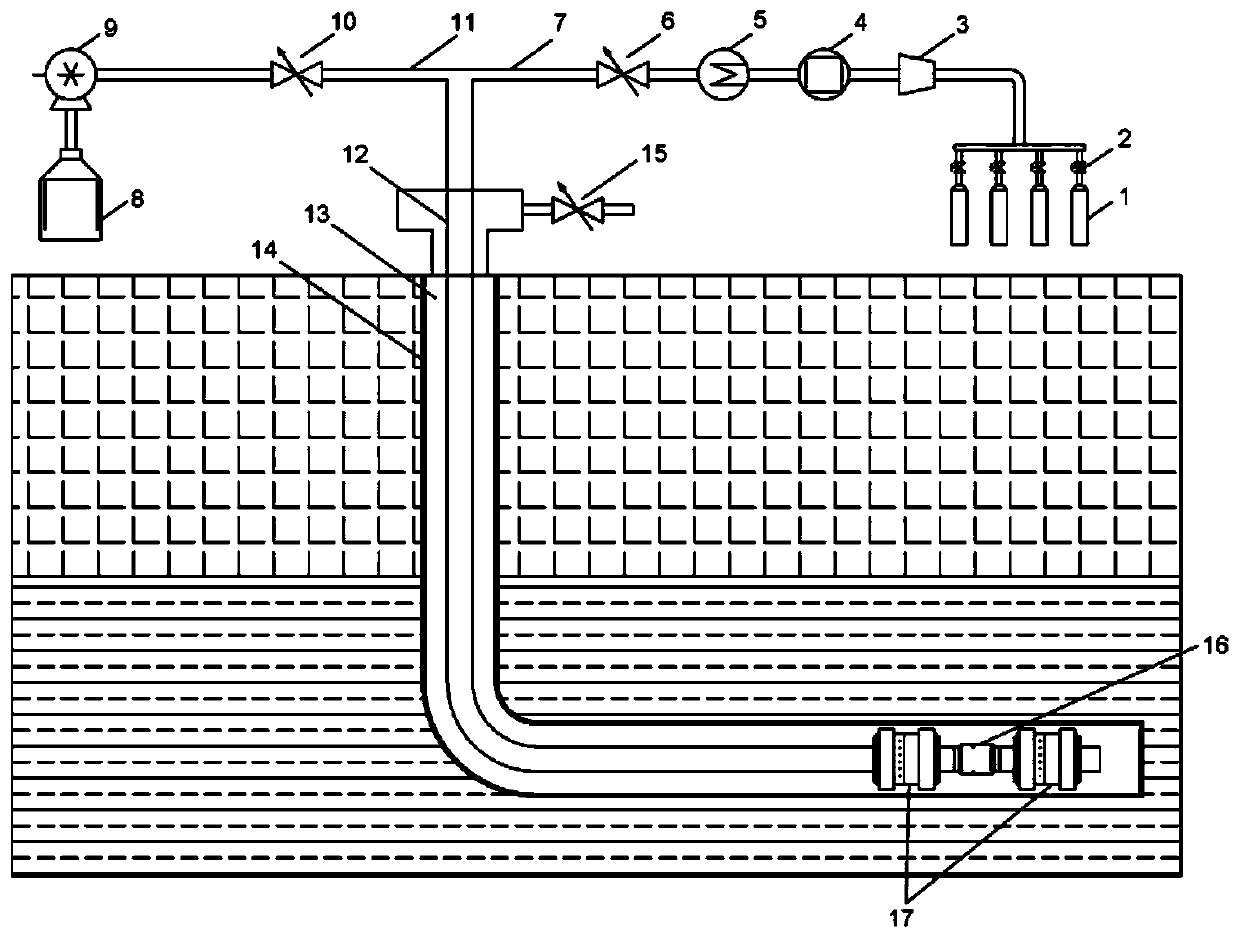

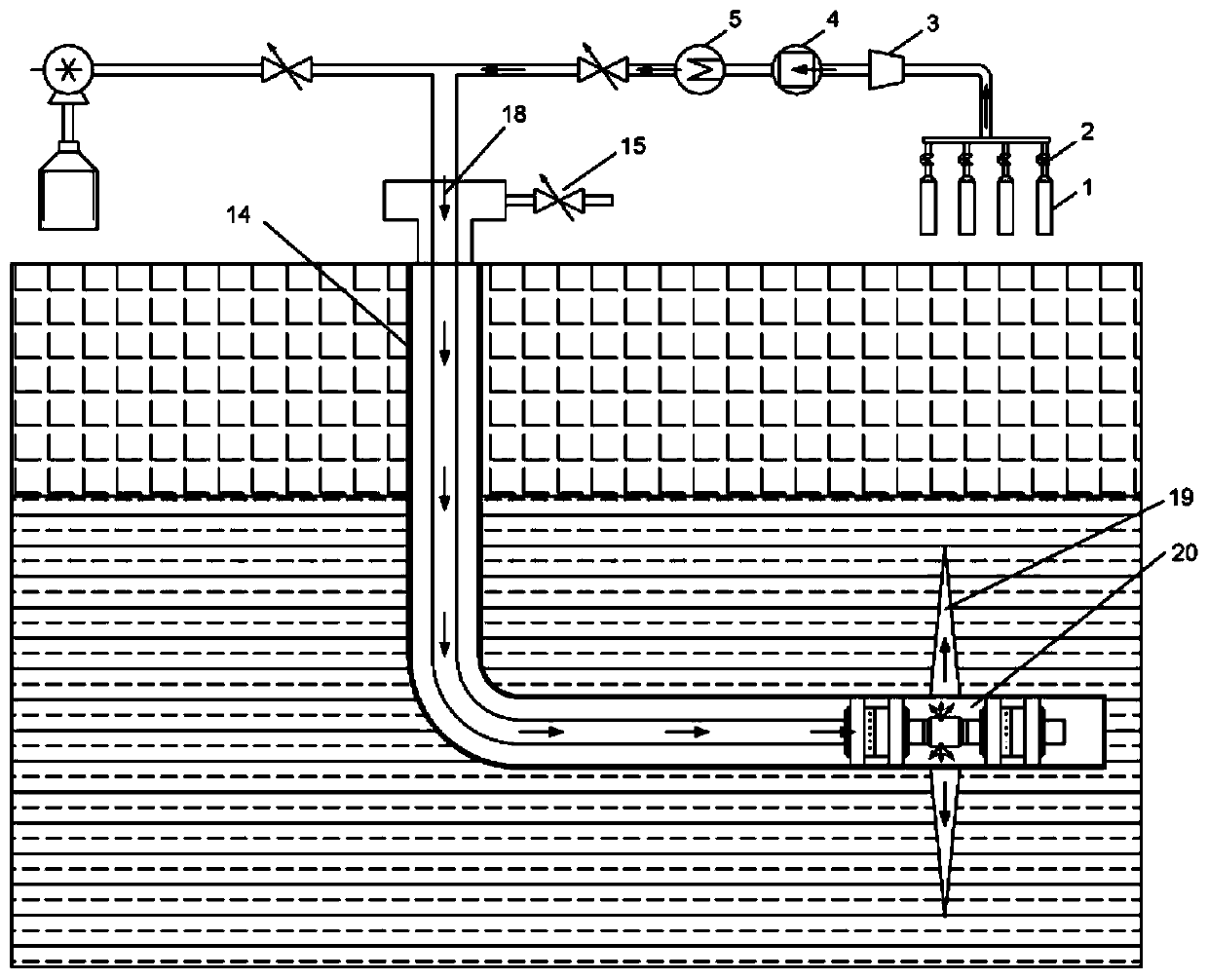

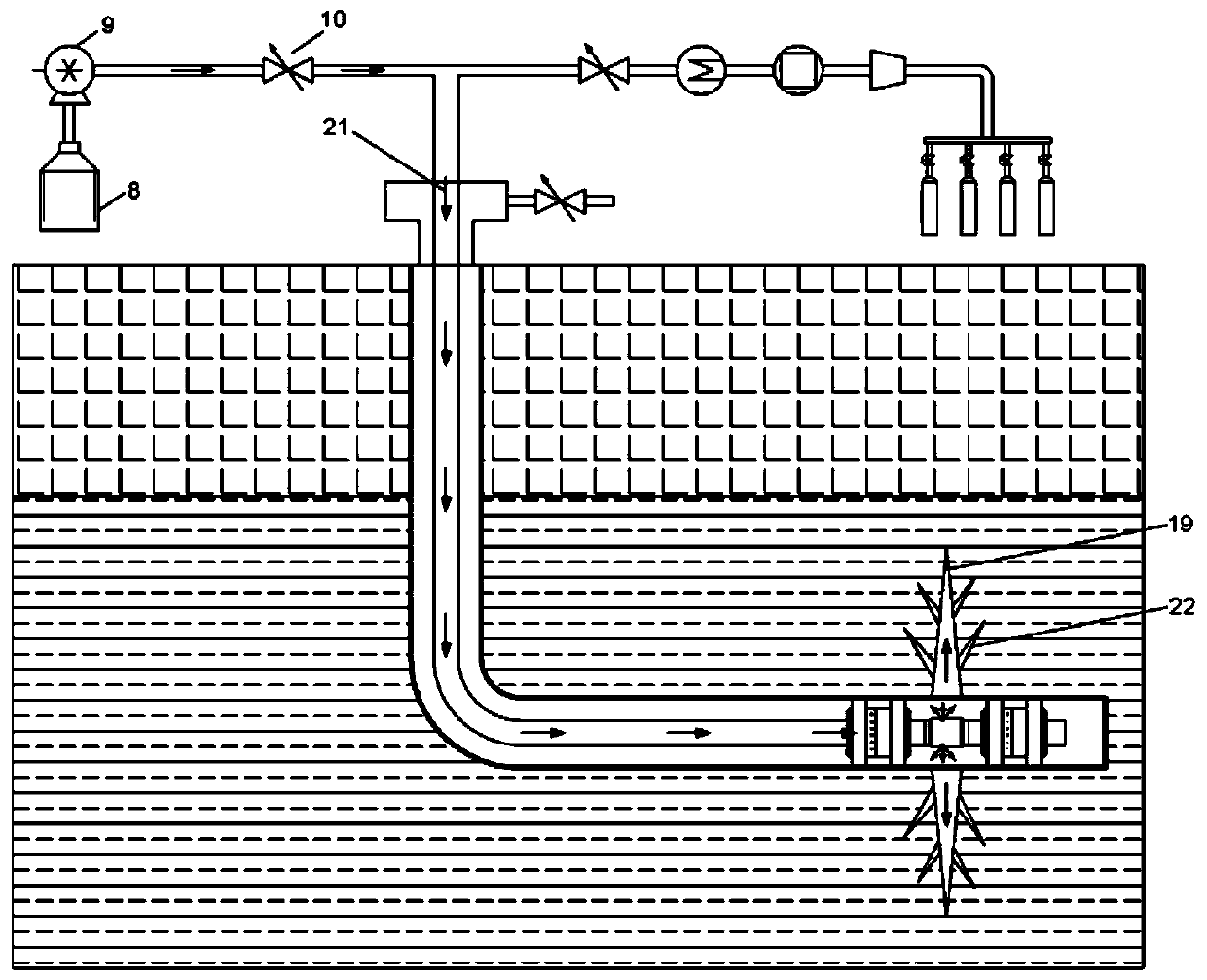

[0034] 1) if figure 1 As shown, a fracturing tool 16 with a packer 17 is lowered into the interval to be stimulated in the wellbore 14 through the oil pipe 12, and then the wellhead is installed and connected to the surface equipment; The nitrogen cylinder group 1, the gas compressor 3, the gas booster 4, the heater 5 and the nitrogen valve 6, and the liquid nitrogen container 8, the liquid nitrogen plunger pump 9 and the liquid nitrogen connected in sequence through the liquid nitrogen injection pipeline 11 The valve 10, the nitrogen injection pipeline 7 and the liquid nitrogen injection pipeline 11 are respectively connected with the oil pipe 12; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com