Arc type magneto-rheology and friction transmission device for electromagnetic thermal memory alloy extrusion

A friction transmission and thermal memory technology, applied in the transmission field, can solve the problem of wasting magnetorheological fluid materials, and achieve the effects of saving consumption, reducing costs, and increasing the extrusion strengthening effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

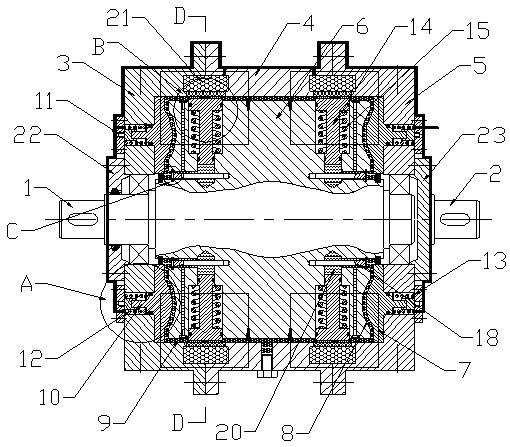

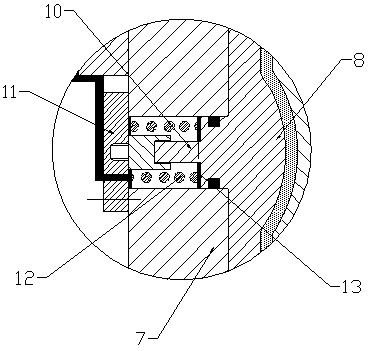

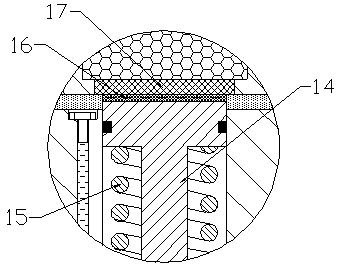

[0034] Example: see Figure 1 to Figure 5 , An arc type magnetorheological and friction transmission device extruded by electromagnetic thermal memory alloy, comprising a driving shaft 1, a driven shaft 2, a left end cover 3, an outer cylinder 4 and a right end cover 5. The left end cover 3, the outer cylinder 4, and the right end cover 5 are connected in sequence to form a housing. The drive shaft 1 is connected to the left end cover 3 and the right end cover 5 through a bearing, and its left end passes through the left end cover 3 and extends out of the housing. The driven shaft 2 is fixedly connected with the right end cover 5, and the axis line of the driving shaft 1 and the axis line of the driven shaft 2 coincide. In specific implementation, a through cover 22 is provided on the outer side of the left end cover 3. The through cover 22 is sleeved on the driving shaft 1 and is fixedly connected to the left end cover 3, and is provided between the through cover 22 and the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com