Alloy resistor and preparation method thereof

A technology of alloy resistors and alloys, which is applied in the field of high-power alloy resistors and its preparation, can solve the problems of adjusting resistance with half the effort, large resistance, and aggravated heating, and achieve the effects of maintaining integrity, simple preparation method, and increasing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below, the present invention will be described in further detail in conjunction with the accompanying drawings.

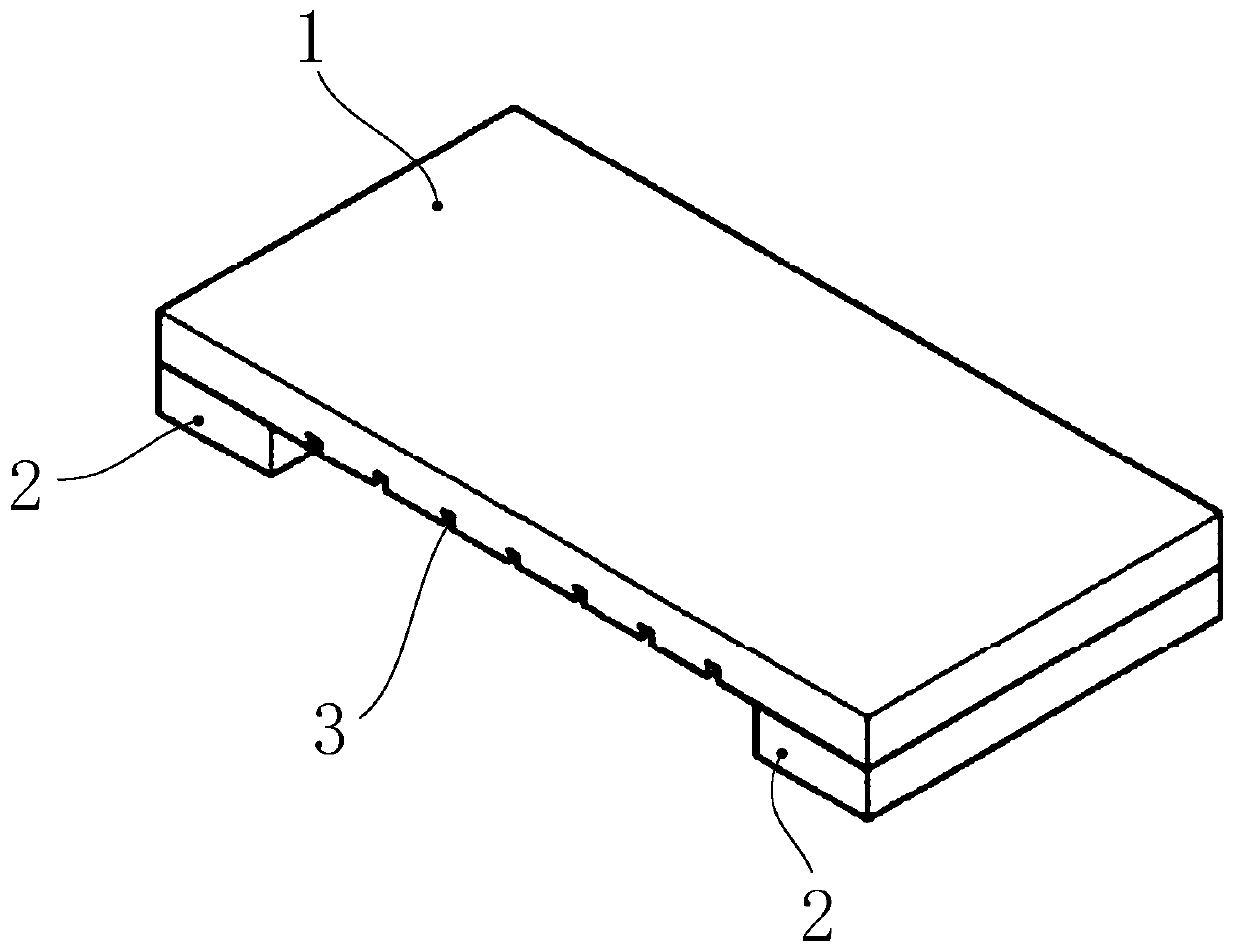

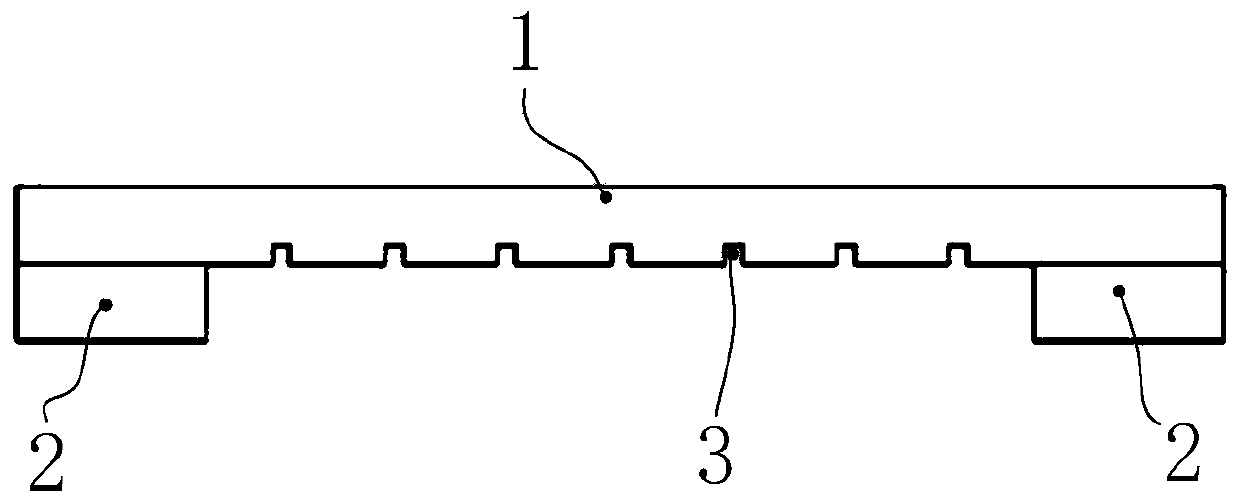

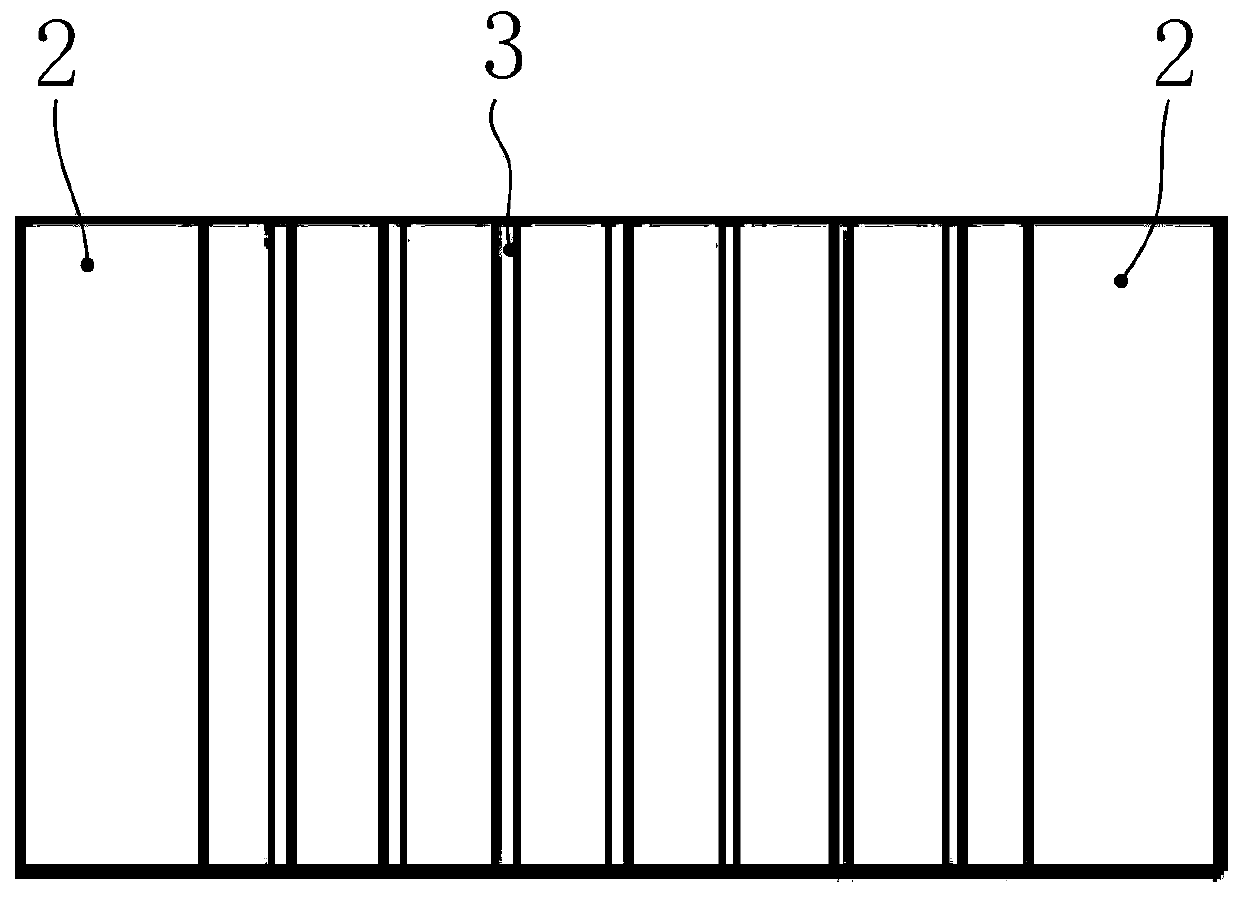

[0025] Such as Figure 1-3 As shown, this embodiment discloses an alloy resistor, which includes a resistor body 1 and two electrodes 2. The resistor body 1 is a sheet-shaped rectangular structure resistor body made of an alloy material, and the electrode 2 is a rectangular resistor body made of a copper material. Sheet electrodes, two electrodes 2 are respectively located at both ends of a surface of the resistor 1 and protrude from the surface, and the long side of the electrode 2 is equal to the short side of the resistor 1, and the two electrodes 2 The long sides are arranged close to the short sides of the two ends of the resistor body 1 respectively.

[0026] The surface of the resistor between the two electrodes 2 has a plurality of grooves 3 that are recessed from the surface to the inside of the resistor 1, and the plurality of grooves 3 are used a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com