Stirring device for preparing magnesium-based composite material, and container

A stirring device and composite material technology, applied to mixers with rotating stirring devices, mixers, chemical instruments and methods, etc., can solve problems such as unsatisfactory stirring effects, reduce void ratio and oxidize slag inclusions, prevent Incorporation of agglomeration enhancer, effect of uniformity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

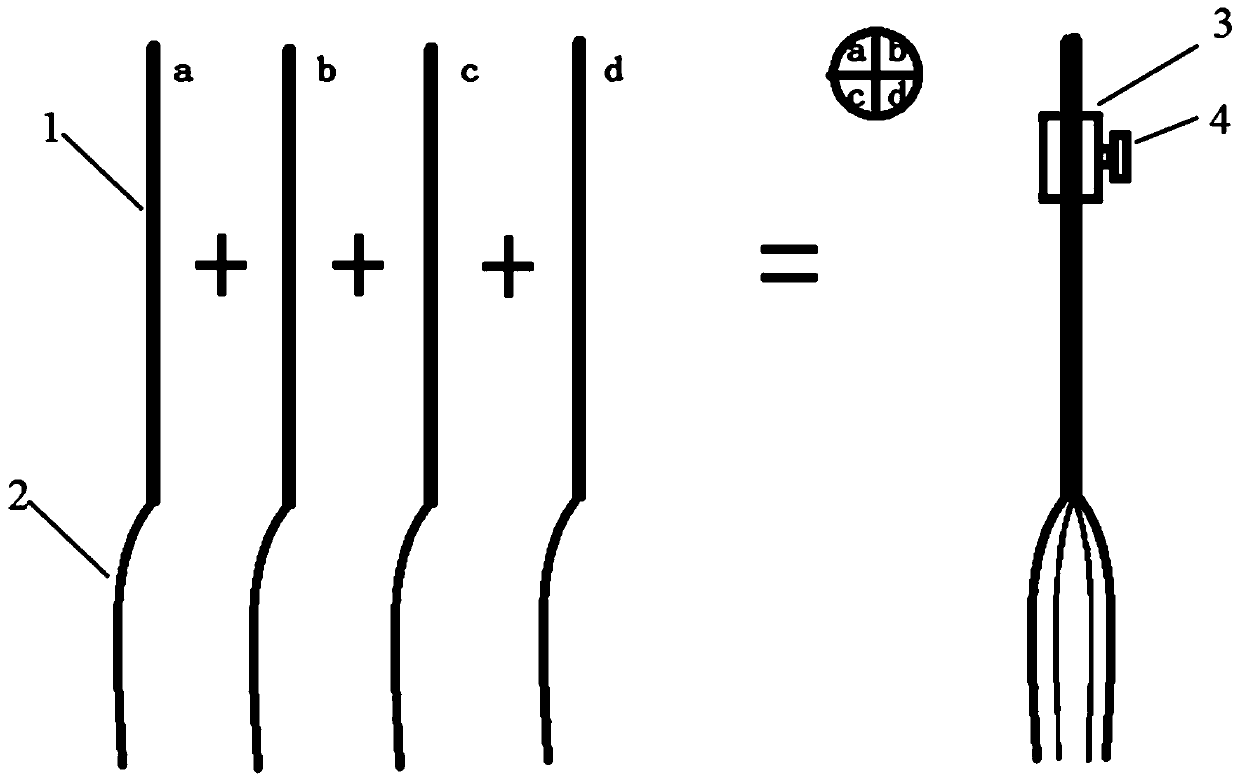

[0075] The stirring paddle used to prepare the magnesium-based composite material includes a single paddle composed of a connecting rod 1 and a stirring paddle 2. After combining four single paddles into a set of stirring paddles, they are inserted into the fixing device 3 and connected by bolts 4 to fix.

[0076] The shape of the stirring blade is a sickle-shaped blade, the initial section is arc-shaped, and the subsequent section is straight-line, which conforms to the streamline form of the J-shaped curve.

[0077] The width of the stirring blade gradually narrows outward from the connecting rod, and the width of the tip of the blade is 50% of that of the root of the blade.

[0078] The cross-sectional dimension of the root of the stirring blade is width:thickness=4:1.

[0079] The axial height of the stirring paddle is 75% of the height of the melt in the crucible, and the ratio of the length of the stirring shaft to the length of the sickle-shaped paddle is 1.6:1. The l...

Embodiment 2

[0091] The stirring paddle used to prepare the magnesium-based composite material includes a single paddle composed of a connecting rod 1 and a stirring paddle 2. After combining four single paddles into a set of stirring paddles, they are inserted into the fixing device 3 and connected by bolts 4 to fix.

[0092] The shape of the stirring blade is a sickle-shaped blade, the initial section is arc-shaped, and the subsequent section is straight-line, which conforms to the streamline form of the J-shaped curve.

[0093] The width of the stirring paddle gradually narrows outward from the connecting rod, and the width of the paddle tip is 70% of that of the paddle root.

[0094] The cross-sectional dimension of the root of the stirring blade is width:thickness=3:1.

[0095] The axial height of the stirring paddle is 90% of the height of the melt in the crucible, and the ratio of the length of the stirring shaft to the length of the sickle-shaped paddle is 0.8:1. The length of th...

Embodiment 3

[0106] The stirring paddle used to prepare the magnesium-based composite material includes a single paddle composed of a connecting rod 1 and a stirring paddle 2. After combining four single paddles into a set of stirring paddles, they are inserted into the fixing device 3 and connected by bolts 4 to fix.

[0107] The shape of the stirring blade is a sickle-shaped blade, the initial section is arc-shaped, and the subsequent section is straight-line, which conforms to the streamline form of the J-shaped curve.

[0108] The width of the stirring blade gradually narrows outward from the connecting rod, and the width of the tip of the blade is 30% of that of the root of the blade.

[0109] The cross-sectional size of the root of the stirring blade is width:thickness=5:1.

[0110] The axial height of the stirring paddle is 50% of the height of the melt in the crucible, and the ratio of the length of the stirring shaft to the length of the sickle-shaped paddle is 2:1. The length o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com