Automatic welding equipment of disc tube type diaphragm

An automatic welding, disc tube membrane technology, applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of dependence on imports, automatic membrane welding production equipment depends on imports, etc., to achieve high production efficiency, High production efficiency and high degree of automation, the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

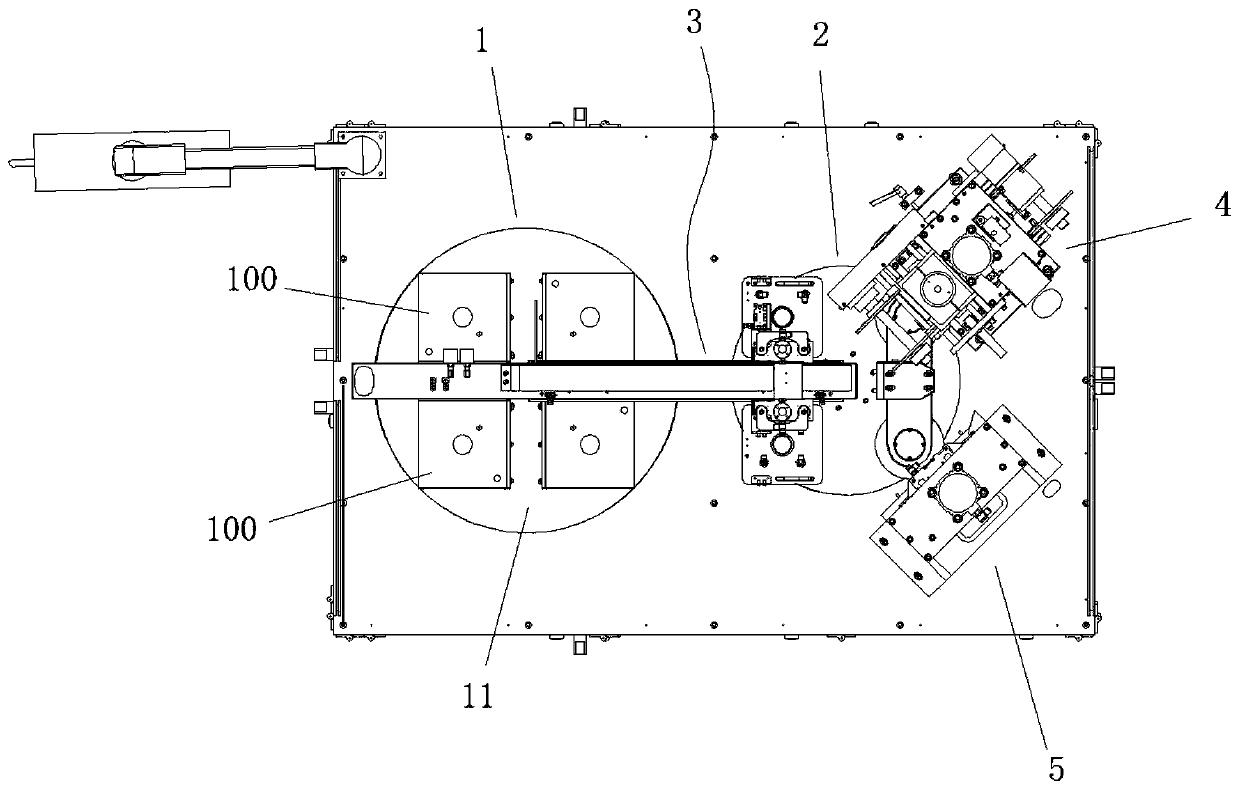

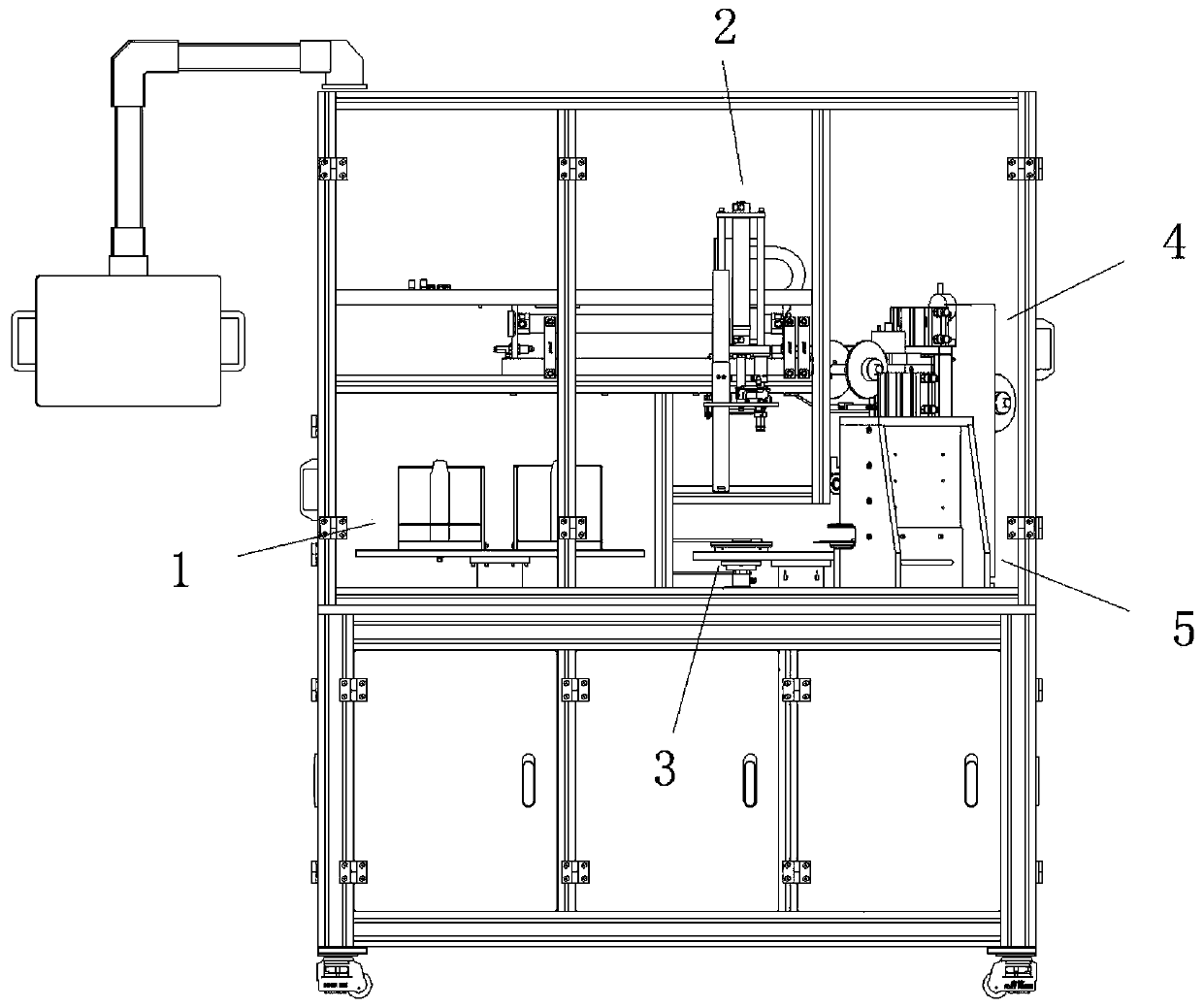

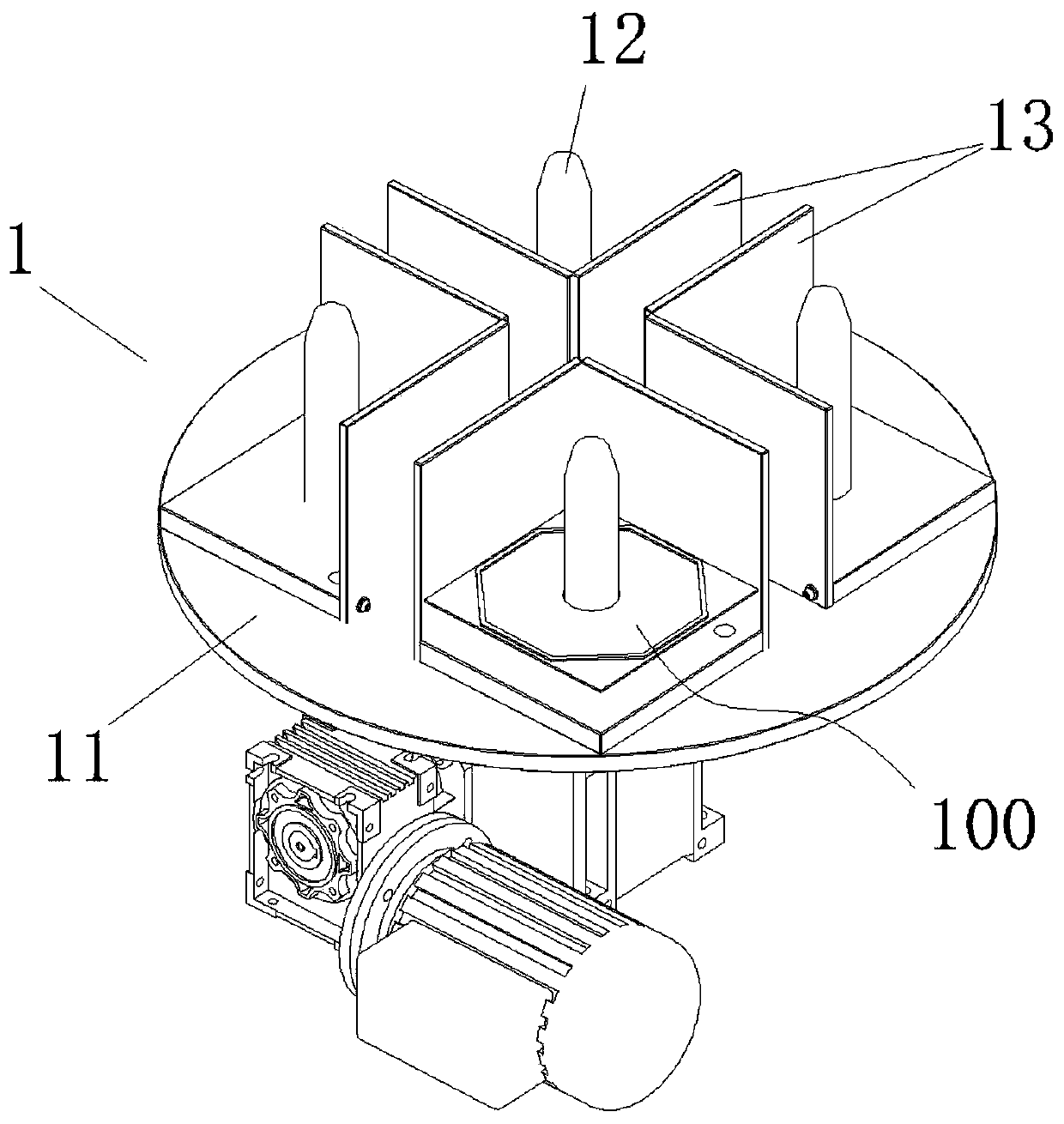

[0029] As shown in the accompanying drawings, the automatic welding equipment for disc tube type diaphragm includes at least the following functional parts: a part for storing materials, a moving part for transferring finished materials and semi-finished materials back and forth, carrying materials and providing them for welding Compared with the material processing part of the cutting process, the part with the welding function and the part with the cutting function, the material processing part uses its own movement to push the material for different processes, that is, pushing the material into the part with the welding function and the part with the cutting function. The functional part is processed.

[0030] This embodiment shows the functionally essential parts of the disc tube type diaphragm automatic welding equipment, divided by function to obtain ① the part used to store materials; ② the moving part used to transfer finished materials and semi-finished materials back ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com