Anti-skid chain ring with no damage to tire and pavement

A technology of anti-skid chains and chain rings, which is applied in anti-skid devices, tire parts, transportation and packaging, etc. It can solve problems such as difficult control of the state, flat tires, and reduced service life of tires, so as to increase the grip force, The effect of not easily moving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

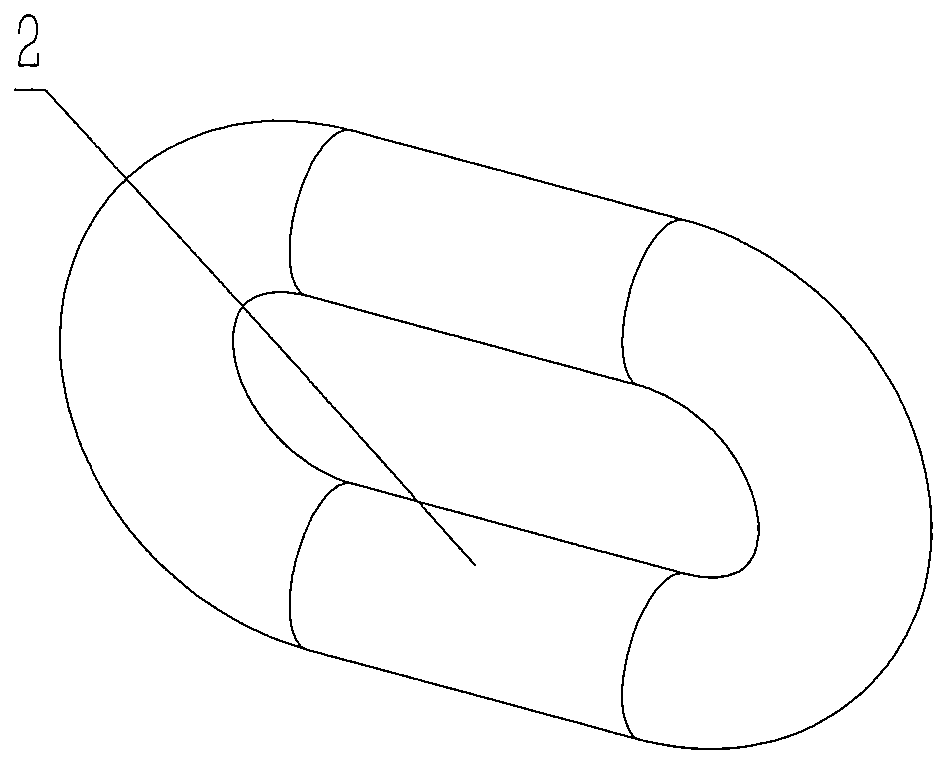

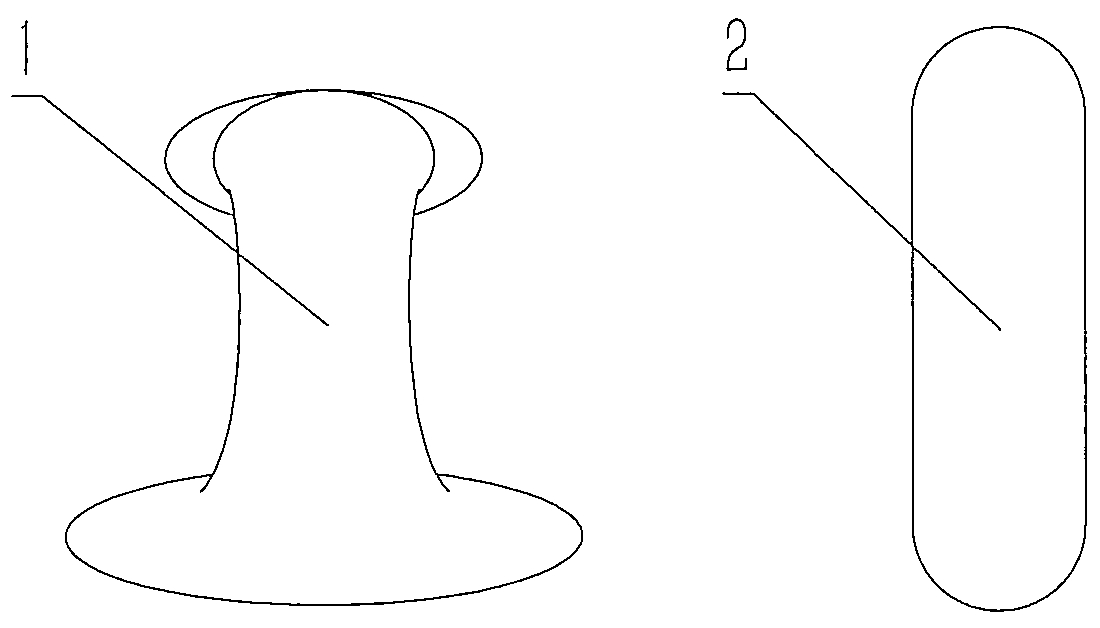

[0025] Embodiment 1: as Figure 5 , Image 6 As shown, when a certain section of anti-skid chain is arranged horizontally on the tire surface, the tire rotates counterclockwise, and the chain link touches the ice and snow road instantly, one side of the flat top formed by the new chain link forms a cut angle with the ice and snow layer, and is planed into The ice and snow layer provides forward power to the tire; when the new chain ring is pressed between the tire and the road, the tire rotates counterclockwise, at this time the brake is applied, the chain ring is blocked and rolls over a certain angle along the tread, the new chain ring The other side of the resulting flat top hooks firmly into the ice and snow, making braking easy and effortless.

Embodiment 2

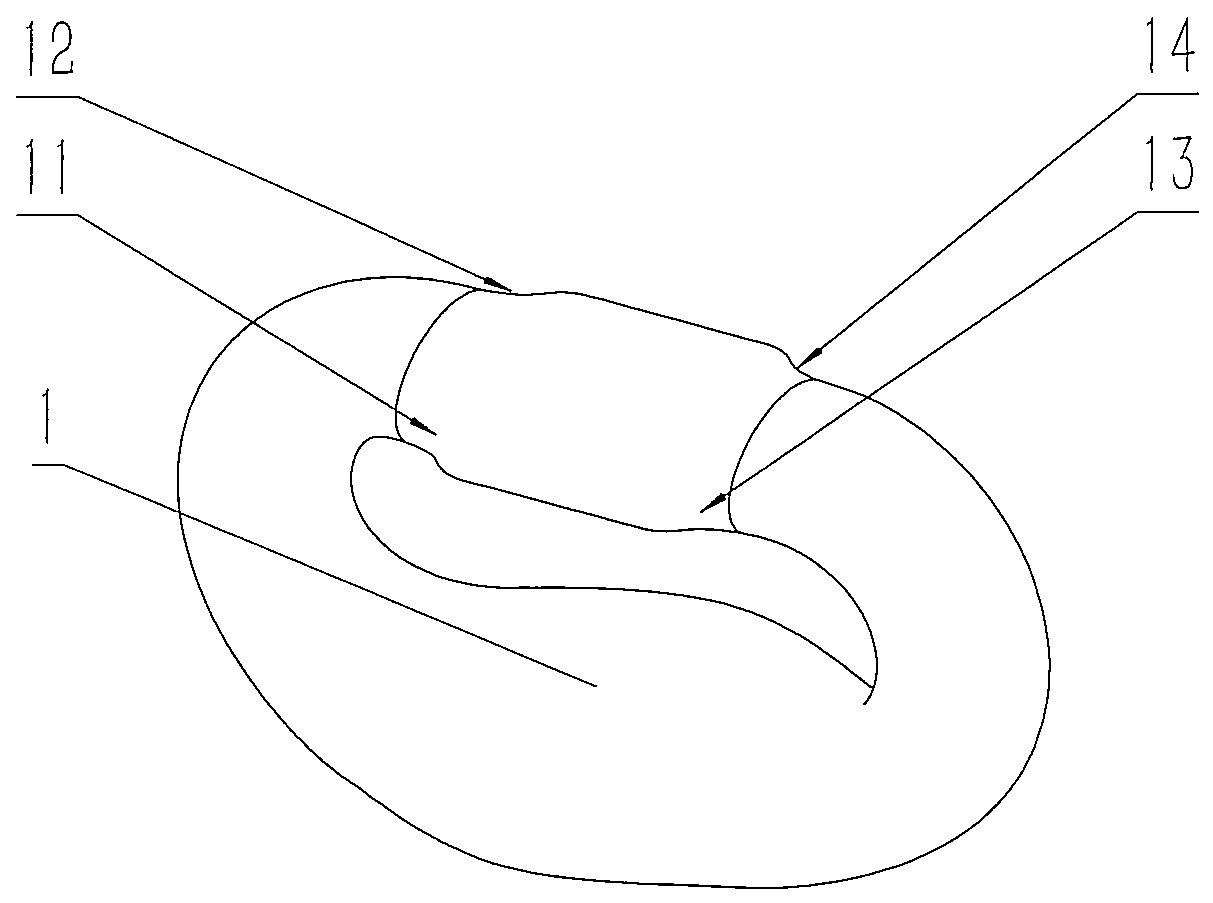

[0026] Embodiment 2: as Figure 7 As shown, when a certain segment of the anti-skid chain is circumferentially arranged on the surface of the tire, the tire rotates counterclockwise, and the new chain ring contacts the ice and snow road, the two "plow" surfaces on the right side of the 11 formed by the new chain ring will scrape and push the ice and snow, Make the tire generate forward power; when the new chain ring is pressed between the tire and the ground, the tire rotates counterclockwise, at this time the brake is applied, and the two "plow" surfaces on the left side of the 13 formed by the new chain ring will Blocking ice and snow, making braking easier.

Embodiment 3

[0027] Embodiment 3: When a certain section of the anti-skid chain is neither circumferentially arranged nor horizontally arranged with the tire surface, that is, it is arranged obliquely, the effects produced by embodiment row 1 and embodiment row 2 will be brought into play at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com